Fruit picking robot end actuator and harvesting method

An end effector and picking robot technology, applied in the field of agricultural robots, can solve the problems of complex control, low efficiency, low level of mechanization, etc., and achieve the effects of simplifying harvesting steps, simple overall structure, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

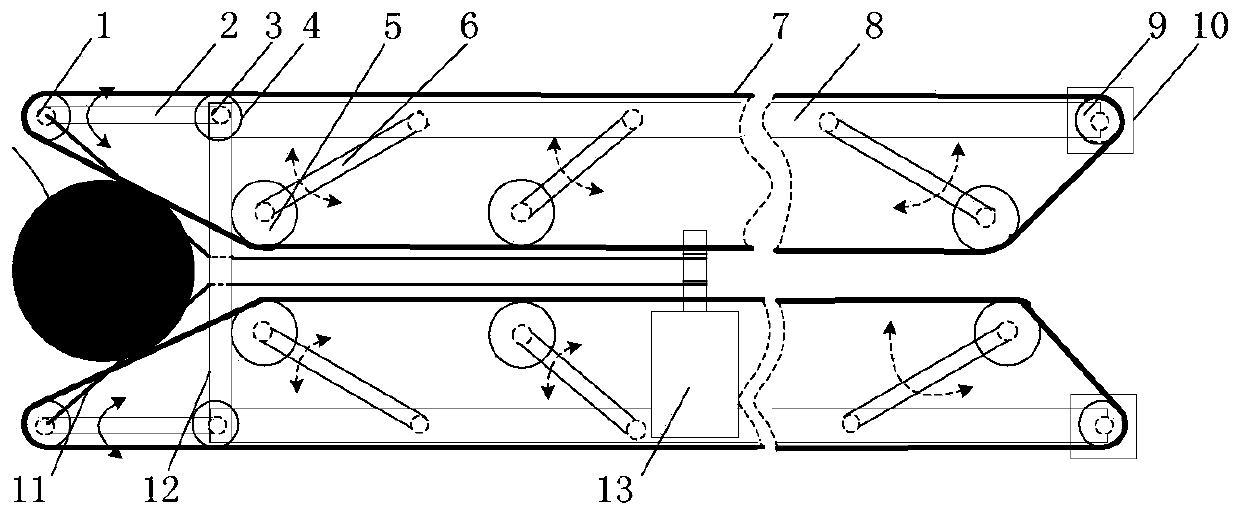

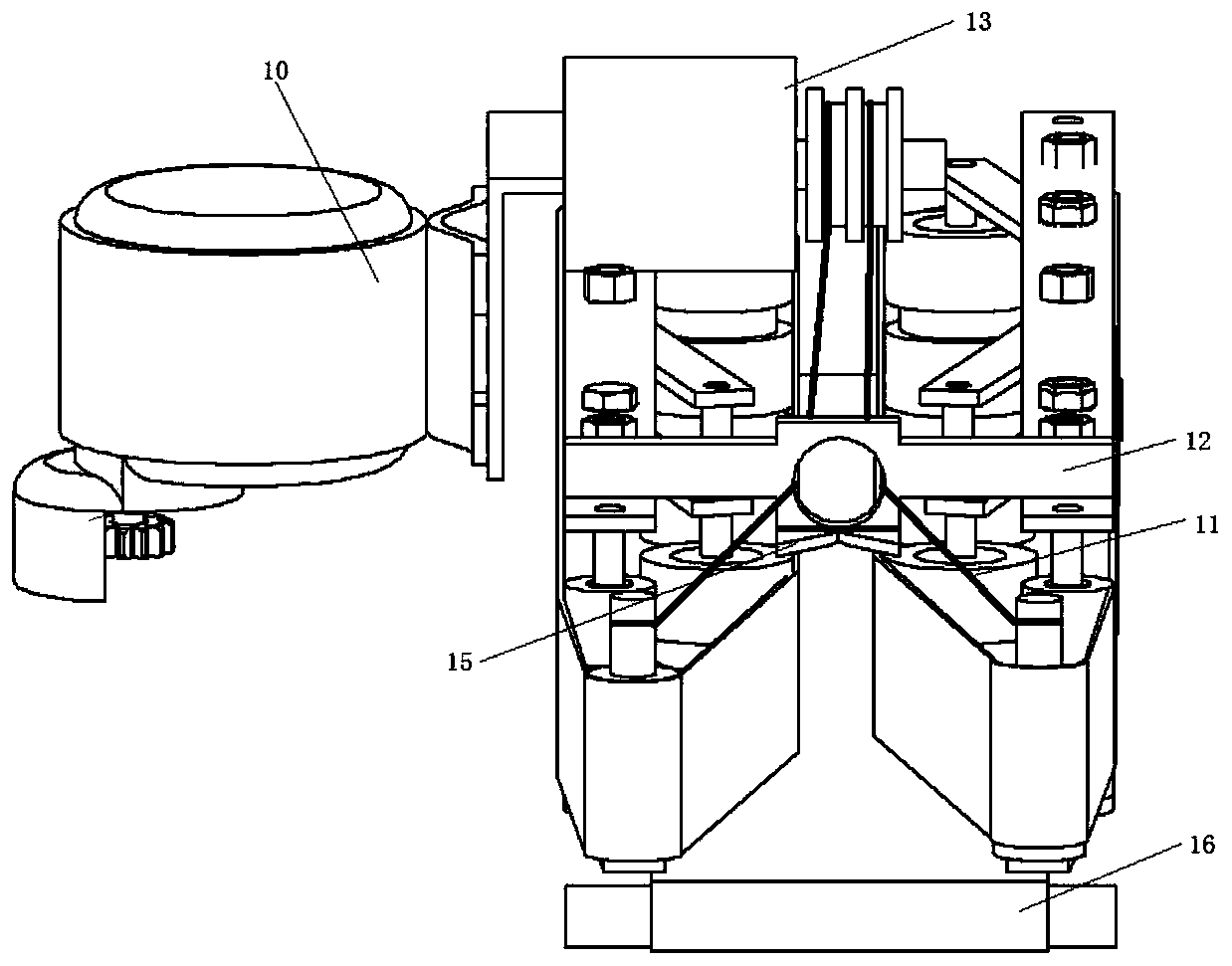

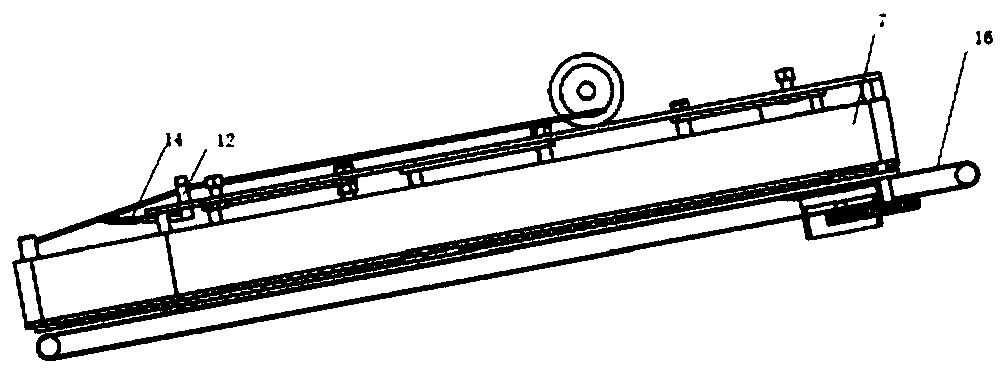

[0026] A fruit picking robot end effector of the present invention includes a frame 8, a flexible belt 7, a support wheel 5, a clamping adjustment mechanism, a floating adjustment mechanism, and a driving mechanism. The frame 8 is the skeleton of the entire end effector, and is used for fixing and installing various auxiliary mechanisms; the flexible belt 7 is used for clamping and picking fruit, and transporting the fruit; the support wheel 5 is used for supporting the flexible belt 7 , to maintain its tension state; the guide mechanism is used to guide the feeding of the fruit and complete the cutting of the fruit handle; the floating adjustment mechanism can adjust the rotation angle according to the size of the fruit and change the opening size of the end effector; The above-mentioned clamping adjustment mechanism is used to change the size of the clamping force to complete the clamping and picking of the fruit; the above-mentioned driving mechanism is used to drive the fle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com