A single-degree-of-freedom piezoelectric turntable and its excitation method

A degree of freedom, piezoelectric technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc. problems, to achieve the effect of expanding applications and improving mechanical output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

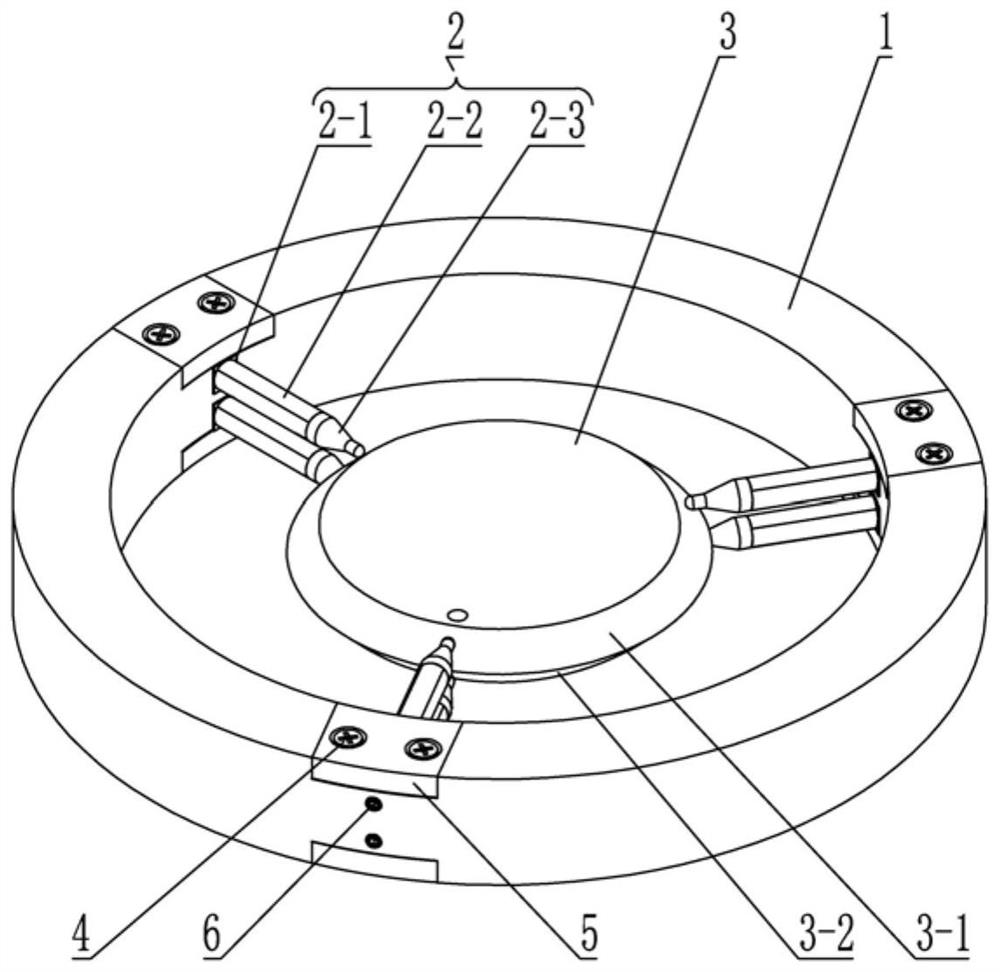

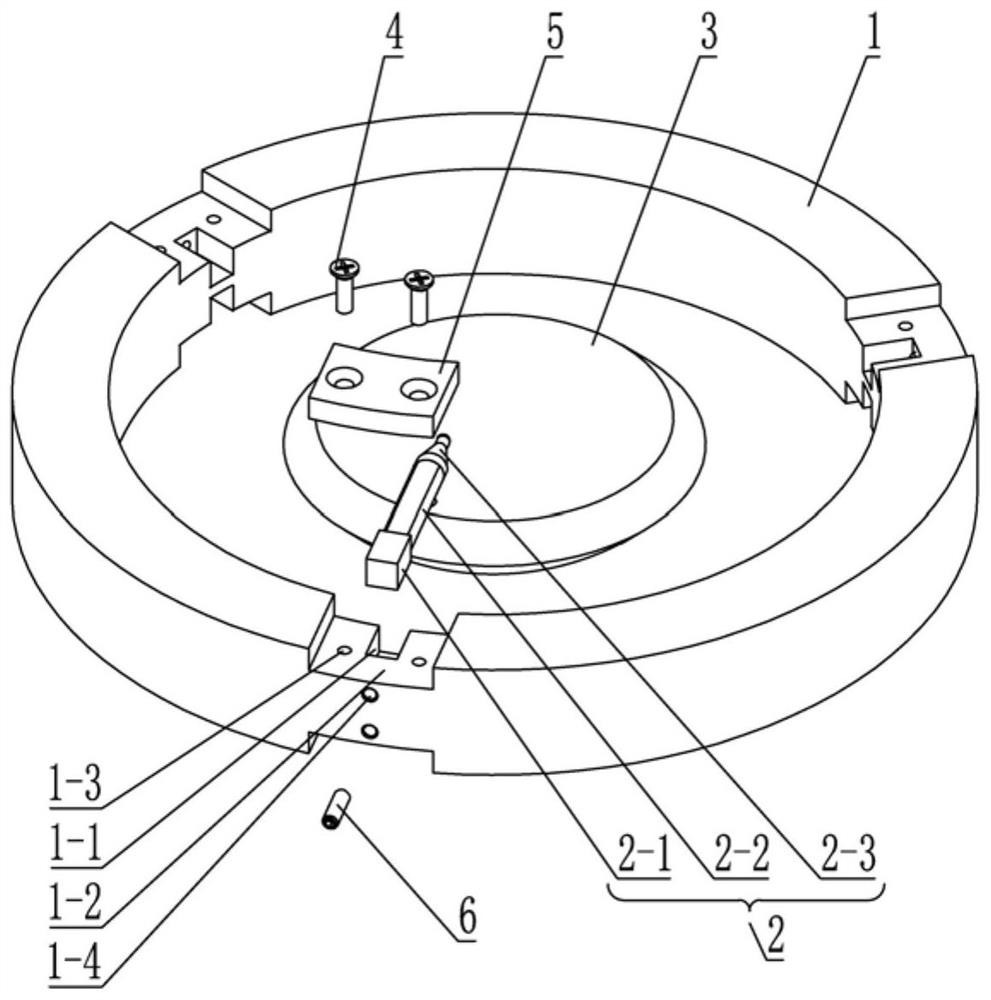

[0036] Specific implementation mode one: in combination with the instructions attached figure 1 And attached figure 2 This embodiment will be further described in detail. This embodiment provides a specific implementation of a single-degree-of-freedom piezoelectric turntable, a single-degree-of-freedom piezoelectric turntable, including an annular base 1, N two-dimensional piezoelectric actuators 2, and a disc mover 3. 2N axial fixing screws 4, N axial compression blocks 5, N radial fixing screws 6, wherein N is an even number greater than or equal to 6; N two-dimensional piezoelectric actuators 2 are divided into The upper and lower layers are evenly distributed on the circumference of the annular base 1, and each of the upper and lower layers includes N / 2 two-dimensional piezoelectric actuators 2; the N two-dimensional piezoelectric actuators 2 have the same structure; Each two-dimensional piezoelectric actuator 2 includes a rectangular base 2-1, a piezoelectric element 2...

specific Embodiment approach 2

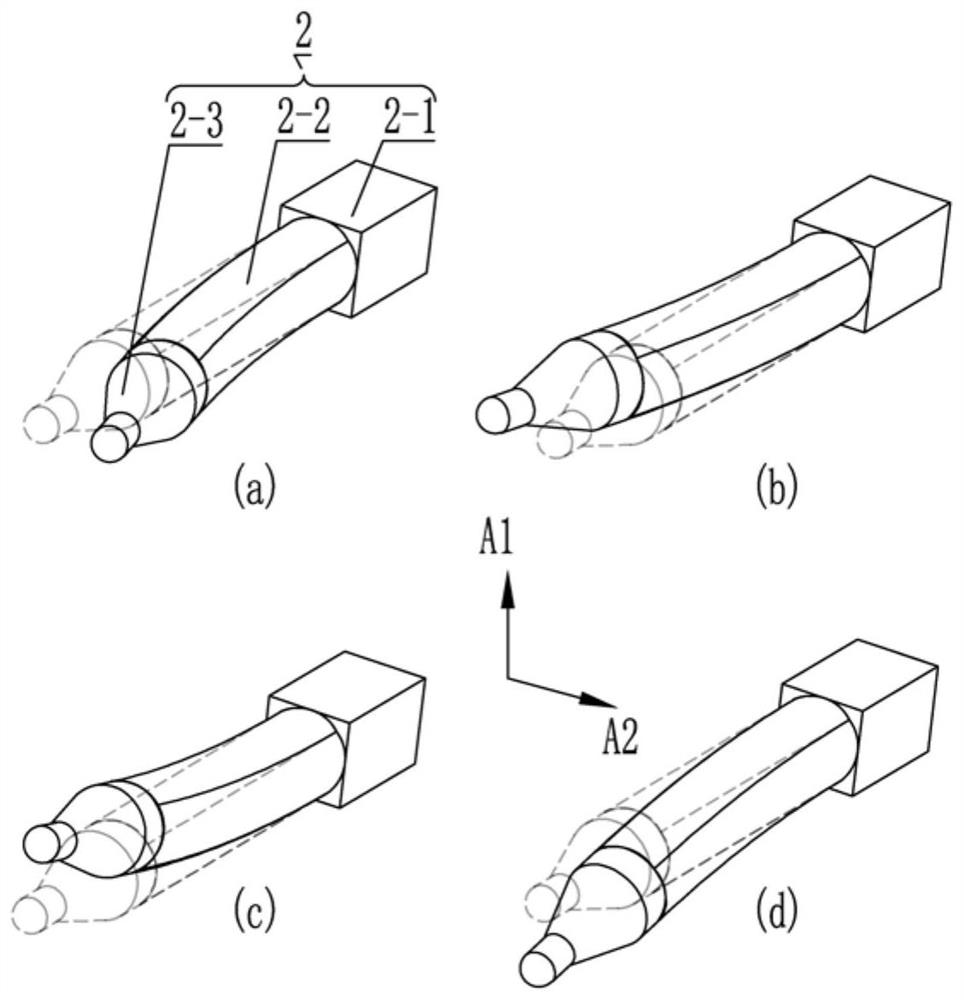

[0037] Specific implementation mode two: in combination with the instruction manual image 3 This embodiment will be further described in detail. This embodiment provides a specific implementation in which a single two-dimensional piezoelectric actuator 2 realizes bending motion along two orthogonal directions A1 and A2. The two-dimensional bending motion that can be realized by a single two-dimensional piezoelectric actuator 2 is as follows: image 3 As shown, by applying an excitation voltage signal to the piezoelectric element 2-2, the positive and negative bending motions along the A2 axis can be realized: when the amplitude of the excitation voltage signal is positive, the two-dimensional piezoelectric actuation Device 2 produces a bending motion along the positive direction of the A2 axis, such as image 3 As shown in (a); when the amplitude of the excitation voltage signal is negative, the two-dimensional piezoelectric actuator 2 produces a negative bending motion alo...

specific Embodiment approach 3

[0038] Specific implementation mode three: in combination with the instruction manual Figure 4 to Figure 8 This embodiment will be further described in detail. This embodiment provides a specific implementation of the excitation method for a single-degree-of-freedom piezoelectric turntable. The Cartesian coordinate system XYZ is established with the center of the disc mover 3 as the coordinate origin, and the Z axis of the coordinate system is aligned with the disc mover 3. If the axes are collinear, then this excitation method can excite the disc mover 3 of the single-degree-of-freedom piezoelectric turntable to achieve counterclockwise or clockwise rotational motion output around the Z axis; the following description is a two-dimensional piezoelectric actuator 2 The case where the number N is equal to six.

[0039] The specific process of driving the disc mover 3 to rotate counterclockwise around the Z axis is as follows:

[0040] Step 1. Apply a slowly decreasing excitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com