Wire twisting method of automatic sleeve penetrating equipment

A technology for automatic casing and equipment, which is applied in coil manufacturing, electrical components, inductor/transformer/magnet manufacturing, etc. problems, to achieve the effect of reducing manufacturing cost and manufacturing difficulty, facilitating the casing threading process, and improving the twisting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be described below in conjunction with specific embodiments.

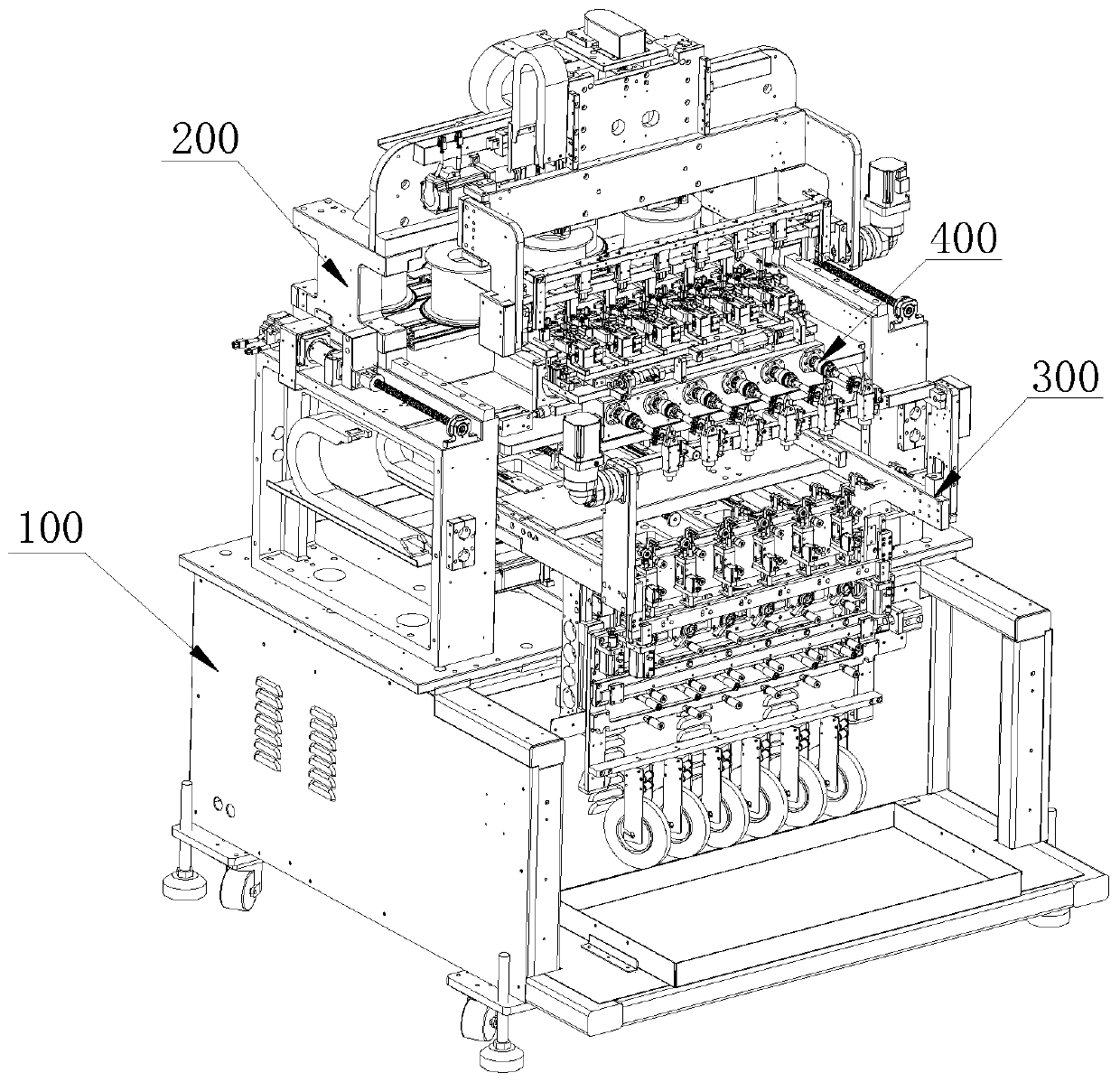

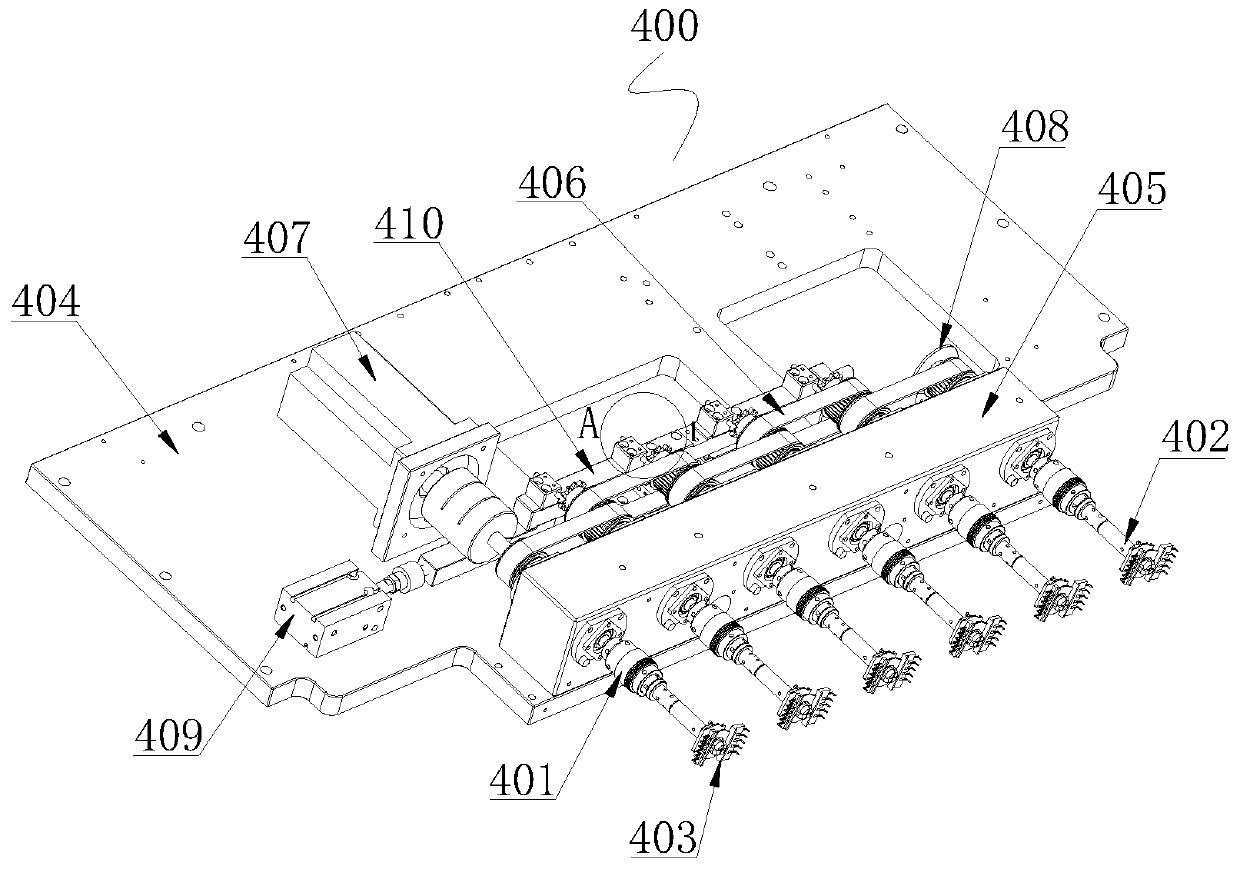

[0020] Such as figure 1 and figure 2 As shown, the twisting method of an automatic casing threading equipment described in the present invention is applied to an automatic multi-axis threading insulation casing winding machine, including a mounting frame 100, an upper XYZ module 200 and a lower XYZ module 300, The upper XYZ module 200 is located on the upper part of the installation frame 100, the lower XYZ module 300 is located below the upper XYZ module 200, and the linear bearing is connected to the installation frame 100, and the middle part of the upper XYZ module 200 is provided with a spindle module 400 , and the lower XYZ module 300 is located below the spindle module 400, the spindle module 400 includes a rotating spindle 401 and a rotating fixture 402, the rotating fixture 402 is installed at the end of the rotating spindle 401, and the rotating fixture 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com