Method for forming SiO2 waveguide based on wafer bonding to realize speckle conversion and speckle converter

A wafer bonding and waveguide technology, applied in the direction of optical waveguide light guide, light guide, instrument, etc., can solve the problem of waveguide thickness limitation, achieve the effects of reducing coupling accuracy requirements, improving coupling efficiency, and process compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

[0031] Formation of SiO based on wafer bonding 2 The method of waveguide to achieve mode spot conversion, such as Figure 1-8 shown (the shaded part is SiO 2 ), including the following steps:

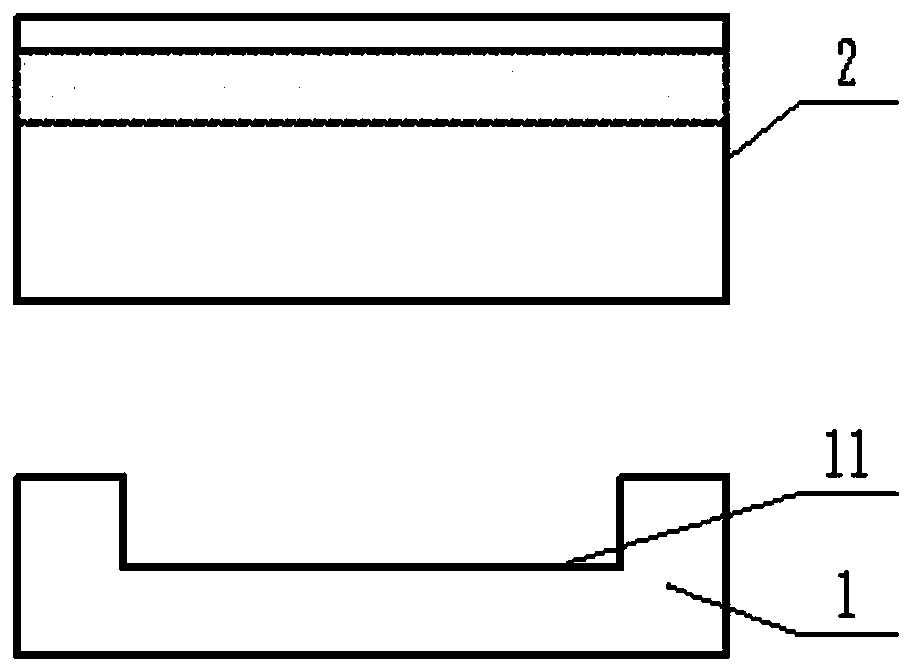

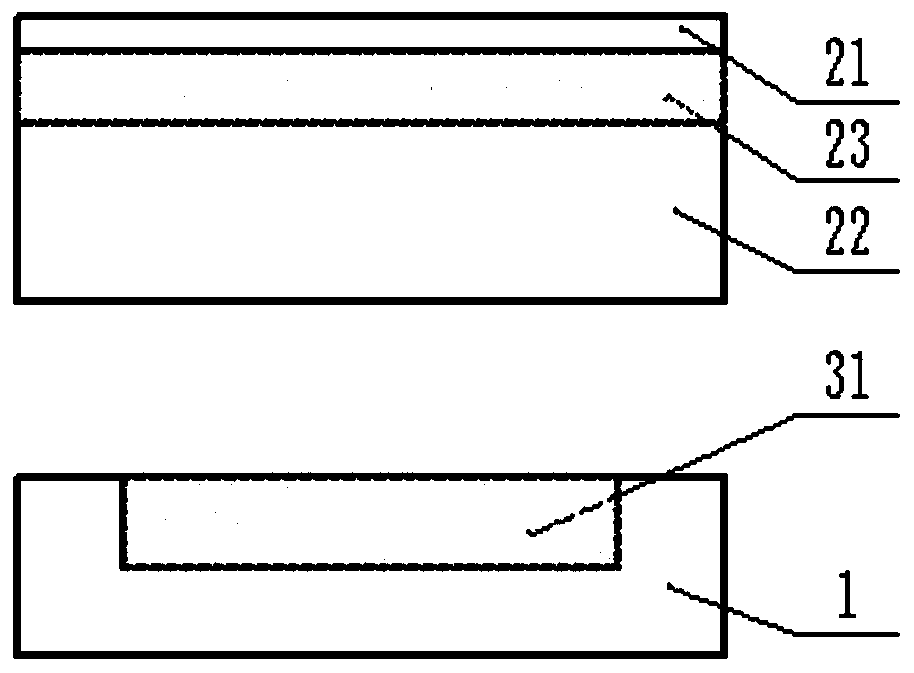

[0032] S1: Prepare a silicon substrate 1 and an SOI wafer 2, and etch a groove 11 on the silicon substrate 1 at a position corresponding to the end-face coupling waveguide, such as figure 1 shown;

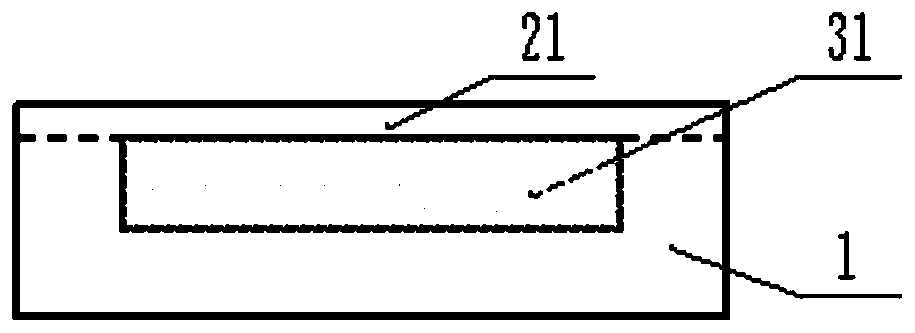

[0033] S2: growing SiO in the groove 11 2 To fill the groove 11, and perform chemical mechanical polishing to ensure that the wafer is flat and form the first SiO 2 waveguide layer 31, to complete the preparation of the substrate silicon wafer, such as figure 2 shown;

[0034] S3: Clean the surface of the SOI wafer 2 to ensure that the surface of the SOI wafer 2 is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com