Light guide body and vehicle knob structure with same

A technology of light guides and knobs, applied in patterns, optics, light guides and other directions characterized by light projection effects, can solve the problems of large space location, high cost, occupation, etc., and achieve compact and reasonable structure, simple layout, and uniform light output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

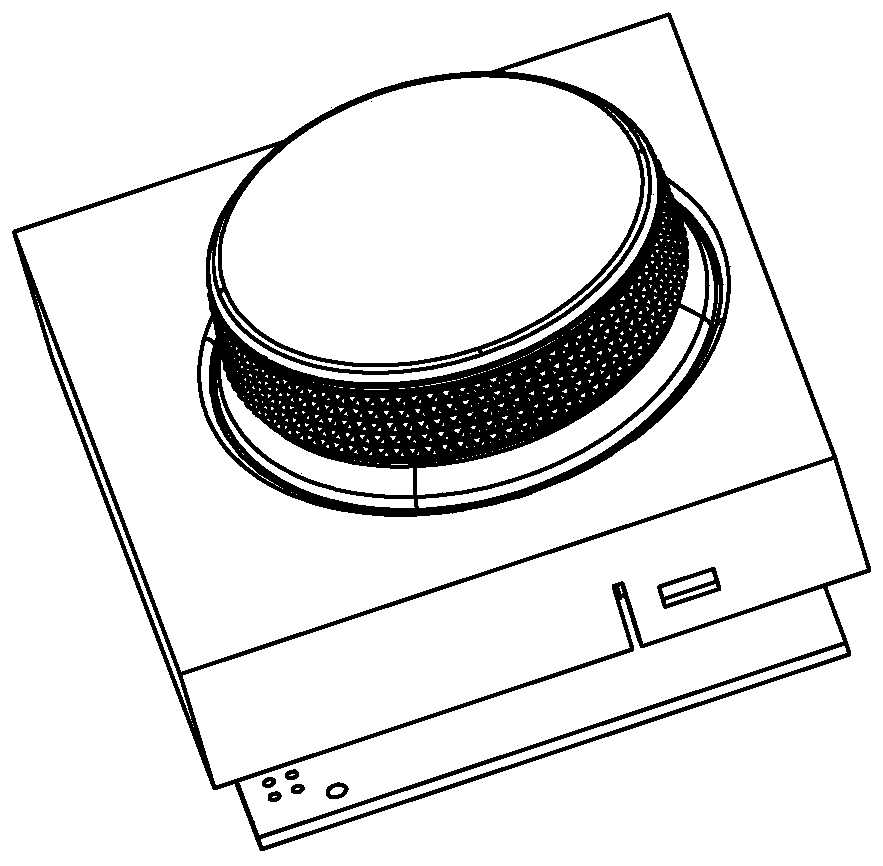

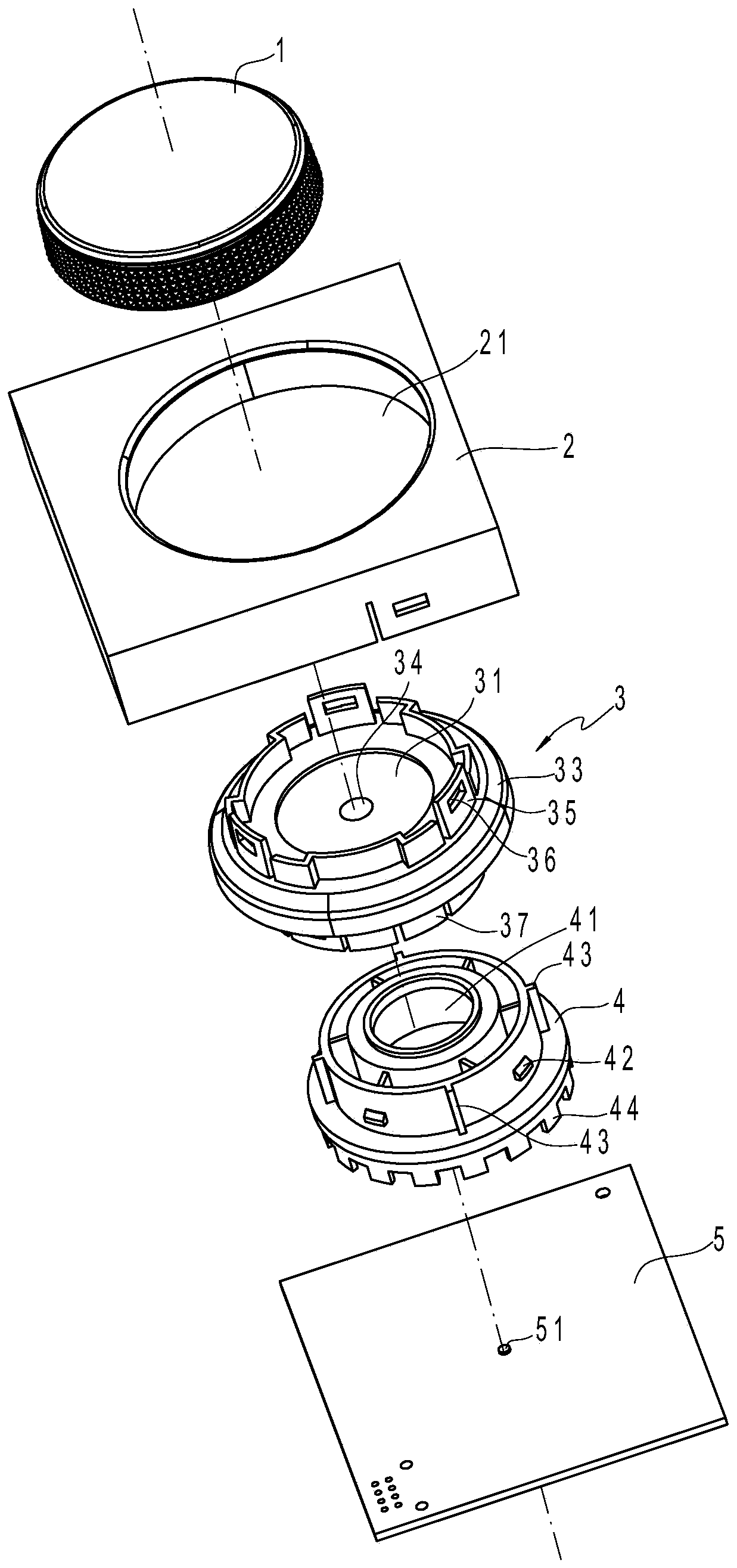

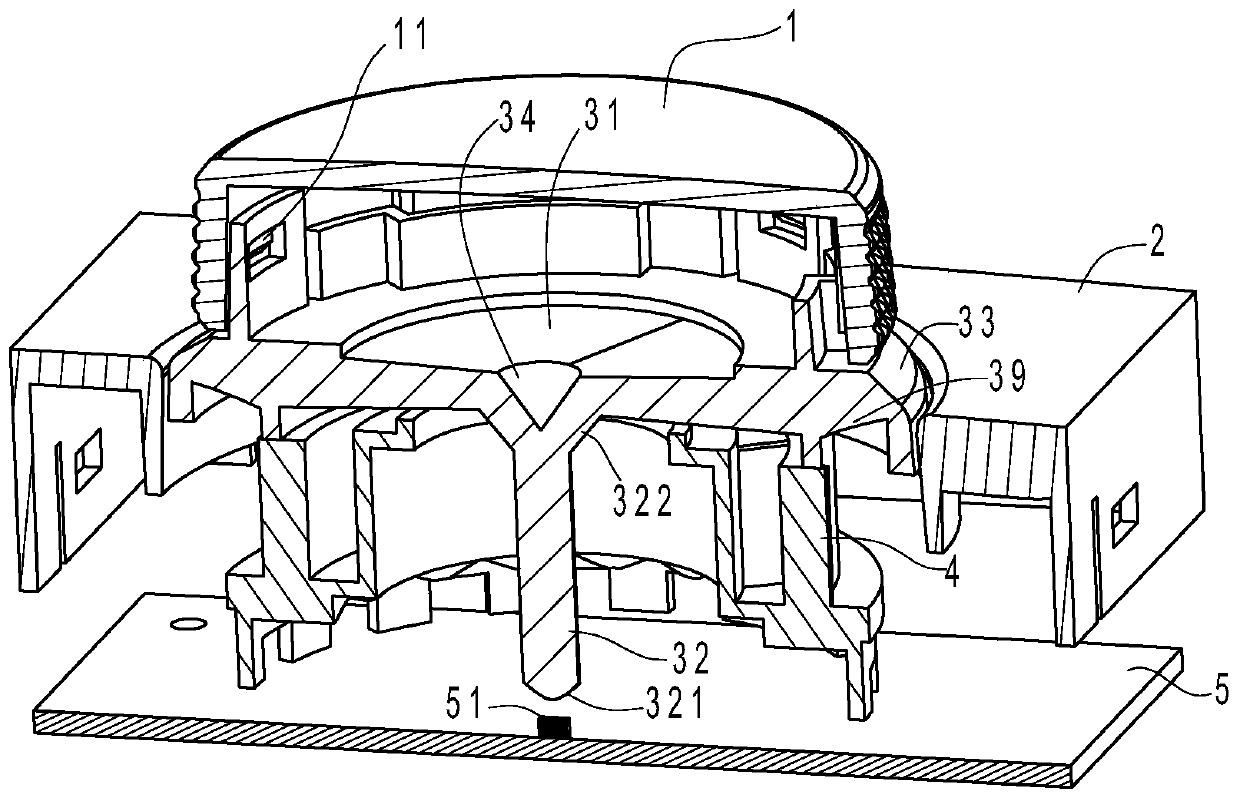

[0023] like figure 1 and figure 2 As shown, the vehicle knob structure in this embodiment includes a panel 2 , a knob 1 , a light guide 3 , a bracket 4 and a circuit board 5 . The panel 2 has a cavity 21; the knob 1 is rotatably disposed in the cavity 21 of the panel 2, and there is an annular gap, preferably 5mm, between the outer periphery of the knob 1 and the inner wall of the cavity.

[0024] The light guide 3 is rotatably arranged in the cavity of the panel 2 and the upper end is connected with the knob 1. The light exit portion 33 of the light guide 3 is located in the annular gap and exposes the light surface; since the light exit surface is not blocked, the brightness is higher. High, with energy-saving effect.

[0025] The bracket 4 is axially hollow to form a central through hole 41 for the vertical light guide part 32 of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com