Non-woven fabric automatic screen printer

A technology of screen printing machine and non-woven fabric, which is applied in the direction of screen printing machine, screen printing, printing machine, etc. It can solve the problems of unqualified printed textile fabrics and achieve the effect of convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

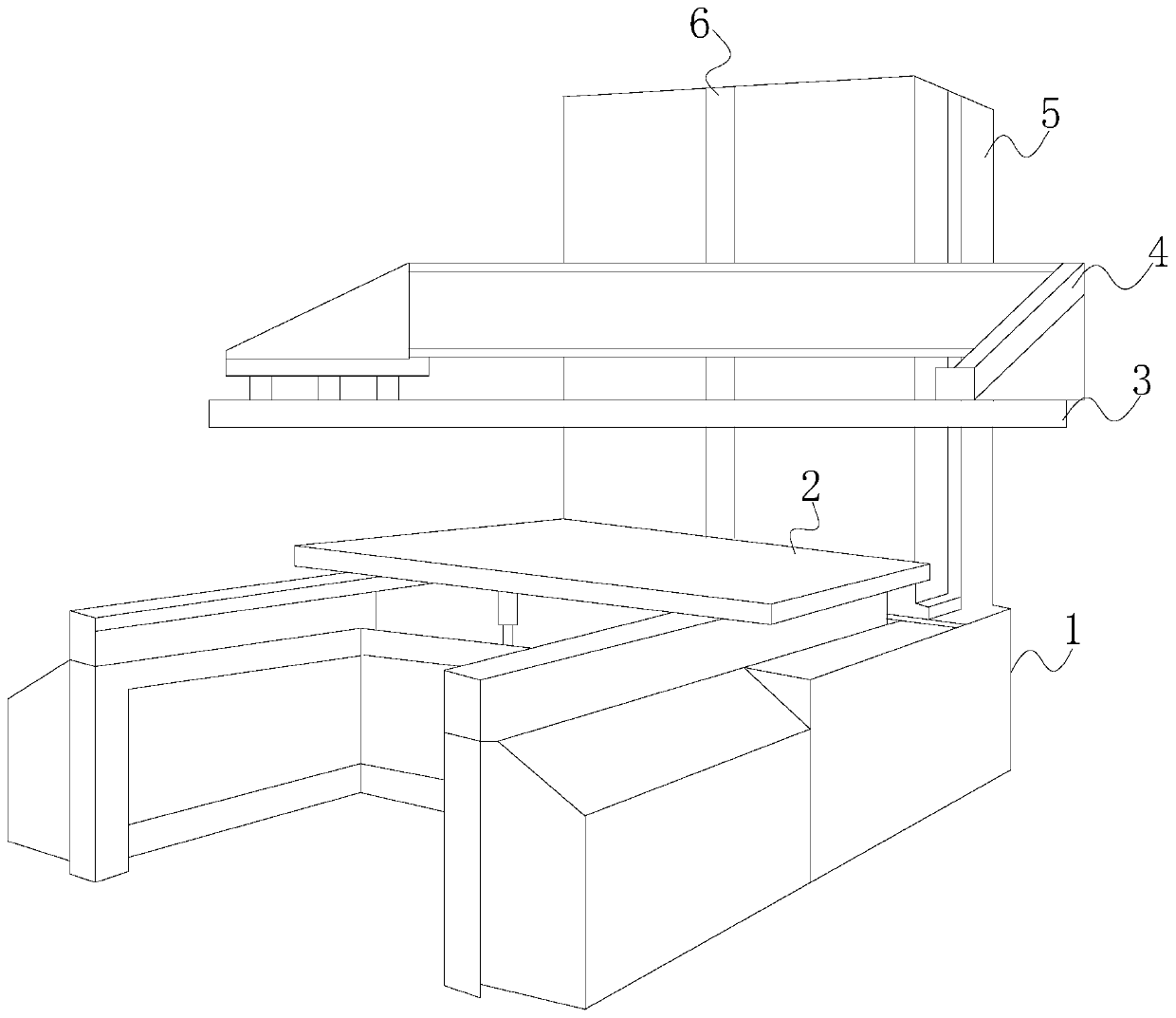

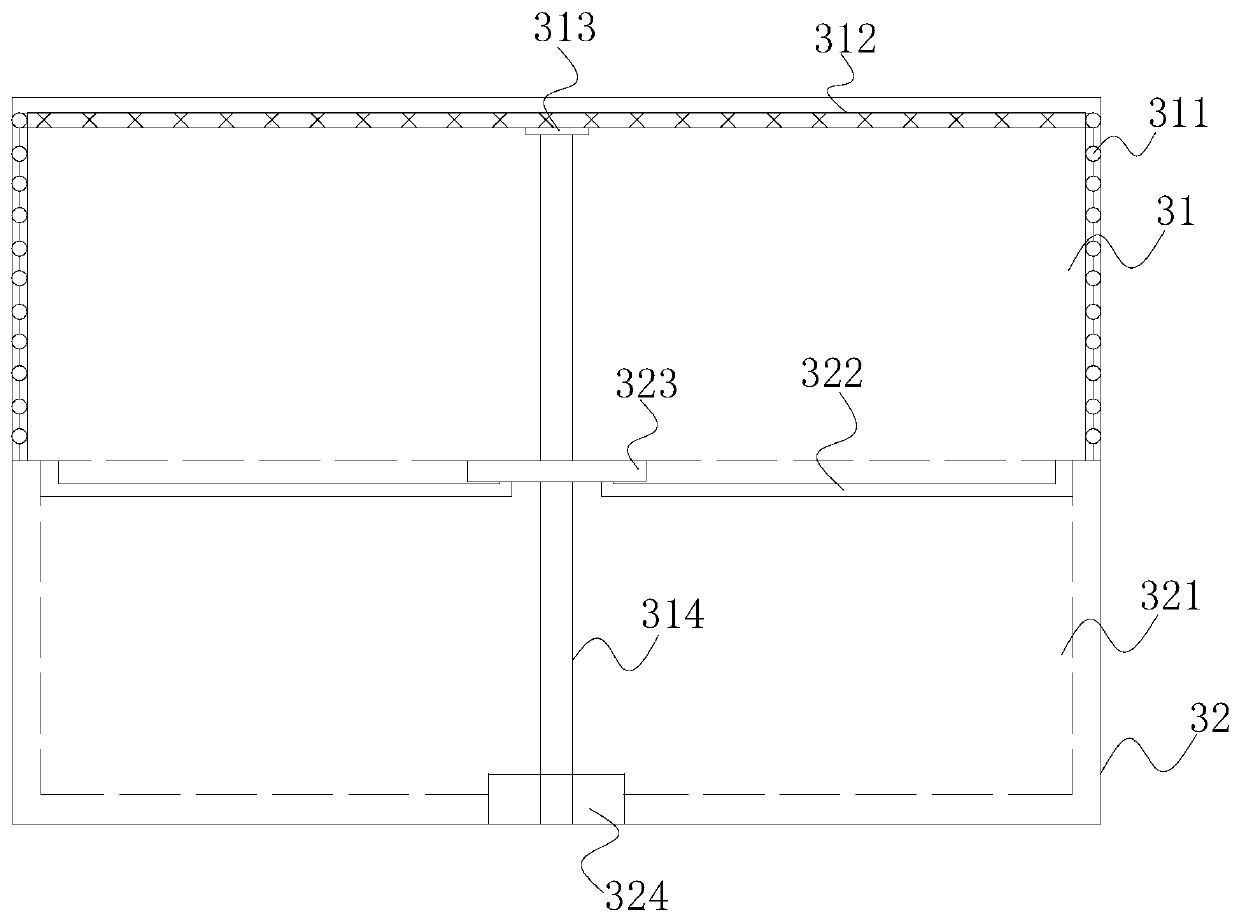

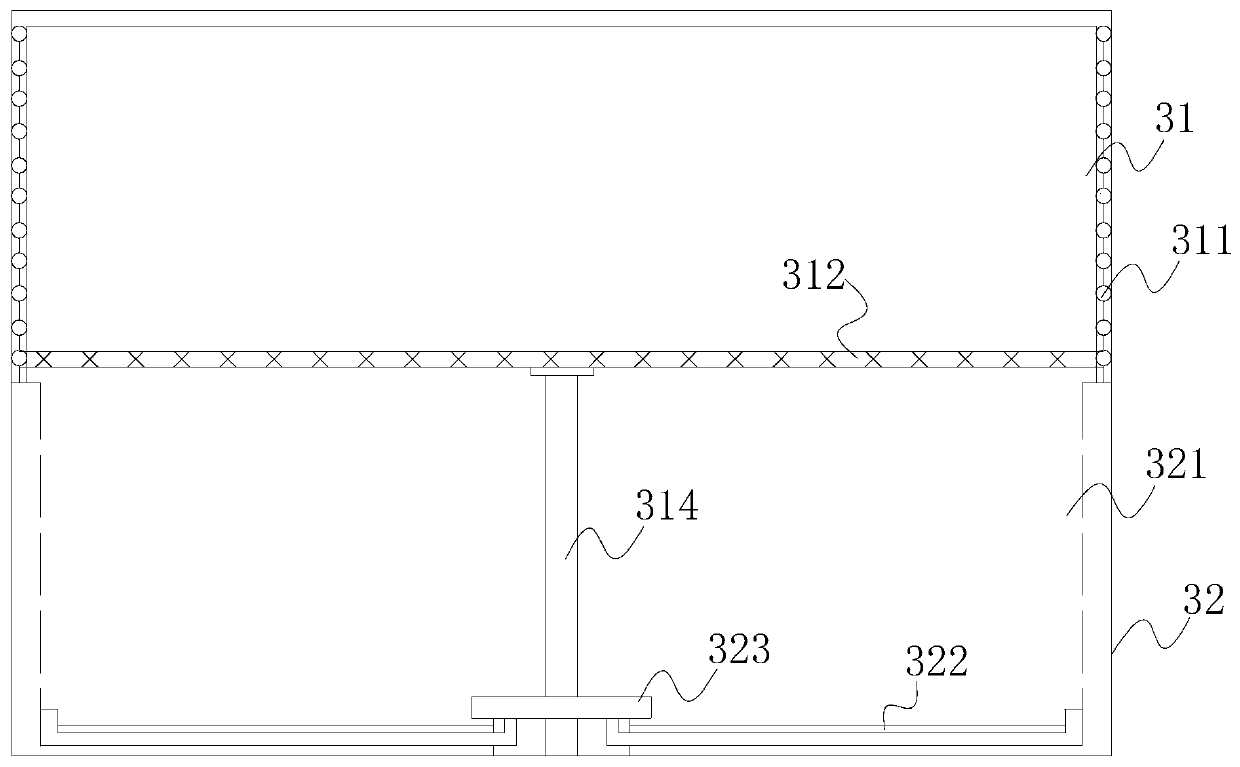

[0028] Such as Figure 1-Figure 4 As shown, the present invention provides an automatic screen printing machine for non-woven fabrics. Its structure includes a base 1, a carrier plate 2, a pressing plate 3, a supporting platform 4, a lift platform 5, and a lifting track 6. The base 1 is fixed with a load Plate 2 and elevator platform 5, described elevator platform 5 is provided with lifting track 6, and described pressing plate 3 is fixed on the bottom of support platform 4, and carrier plate 2 is facing up and down, and the back side of described support platform 4 and lifting track 6 Sliding fit is adopted, and the pressure plate 3 is divided into a pressure surface 31 and a joint surface 32, which are distributed up and down between the pressure surface 31 and the joint surface 32, wherein the pressure surface 31 is lower than the joint surface 32, and the pressure surface 31 is set There are guide rails 311, scrapers 312, connection ports 313, pull bars 314, and scraper in...

Embodiment 2

[0030] combine Figure 4-Figure 5 As shown, the scraper interface 315 is equipped with a combination seat 15a, anastomotic groove 15b, a swing rod 15c, and a rotating core 15d, the combination seat 15a is fixed with the outer surface of the scraper 312, and the swing rod 15c is provided with Two, welded on the frame of the scraper 312, the rotating core 15d is installed on the joint seat 15a, the swing rod 15c is fitted with the anastomotic groove 15b by inserting, and the thickness of the swing rod 15c is greater than that of the anastomotic groove 15b , the pendulum 15c passes through the anastomotic groove 15b and contacts with the surface of the joint seat 15a, the pendulum 15c and the anastomotic groove 15b form a cross structure, through the suction cup composed of antennae, it directly acts on the scraper, when the scraper is subjected to long-term action After a certain degree of wear and tear, the antenna can alarm in time to remind the staff to replace it in time, av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com