Powder management system for SLM equipment

A management system and powder technology, applied in the direction of process efficiency improvement, additive manufacturing, additive processing, etc., can solve the problems of unreasonable powder collection, manual powder addition, and difficulty in secondary powder addition, so as to prevent motor damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

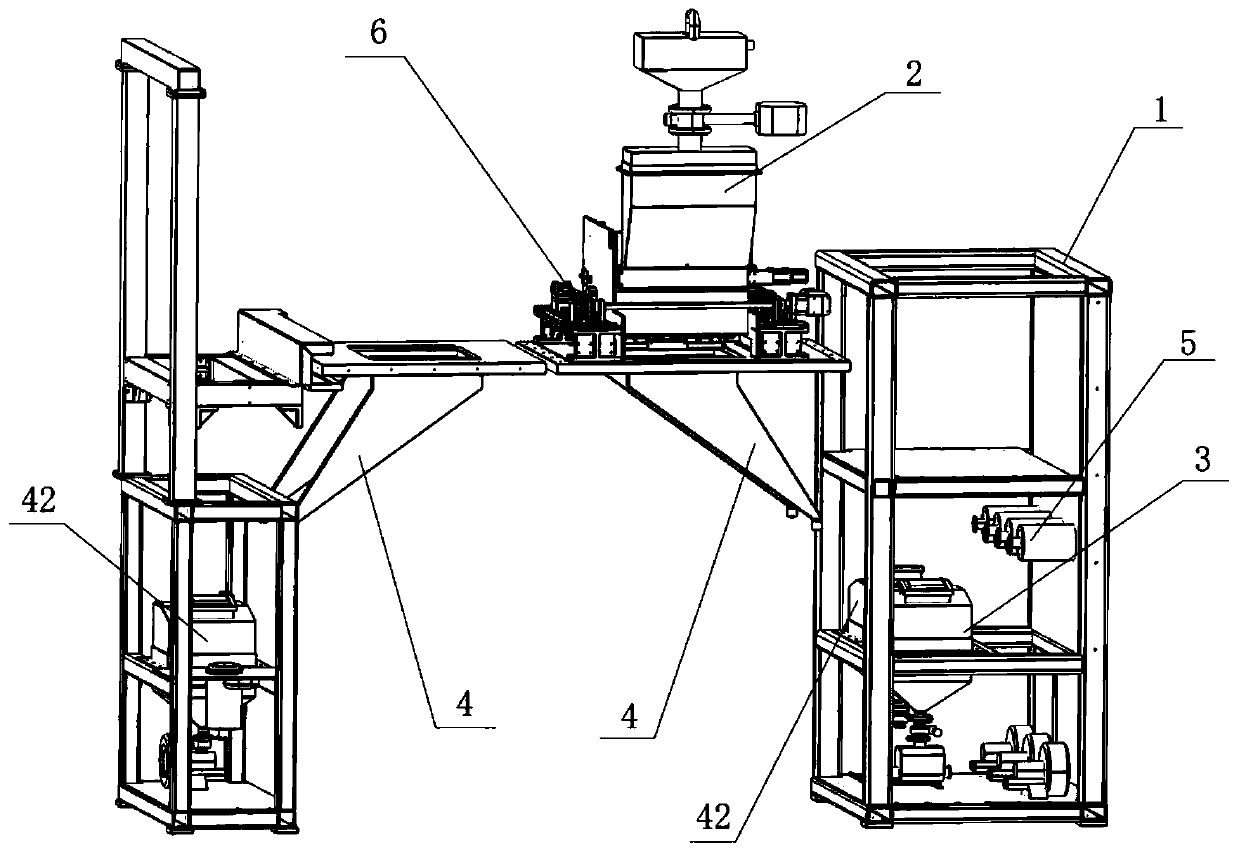

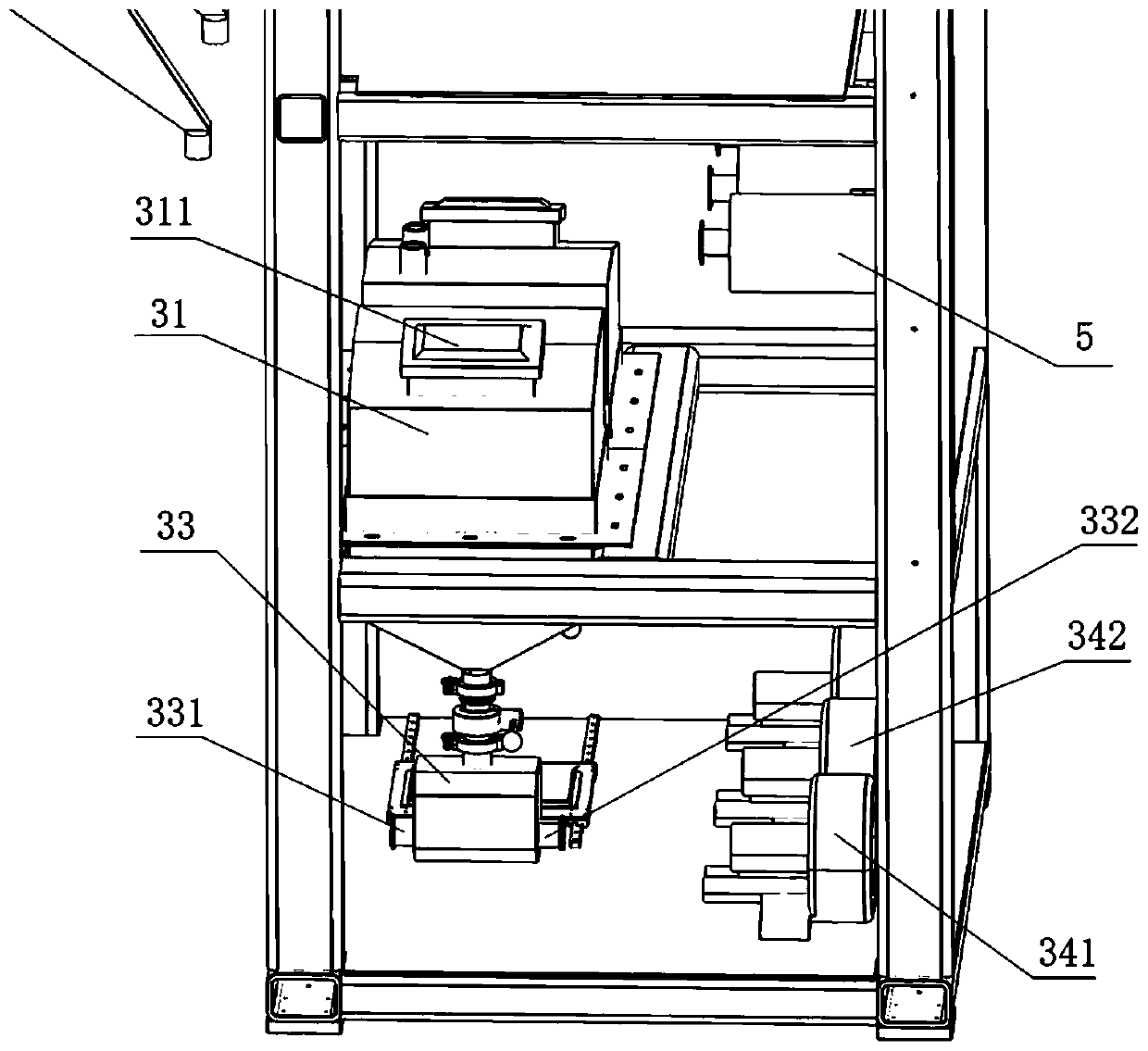

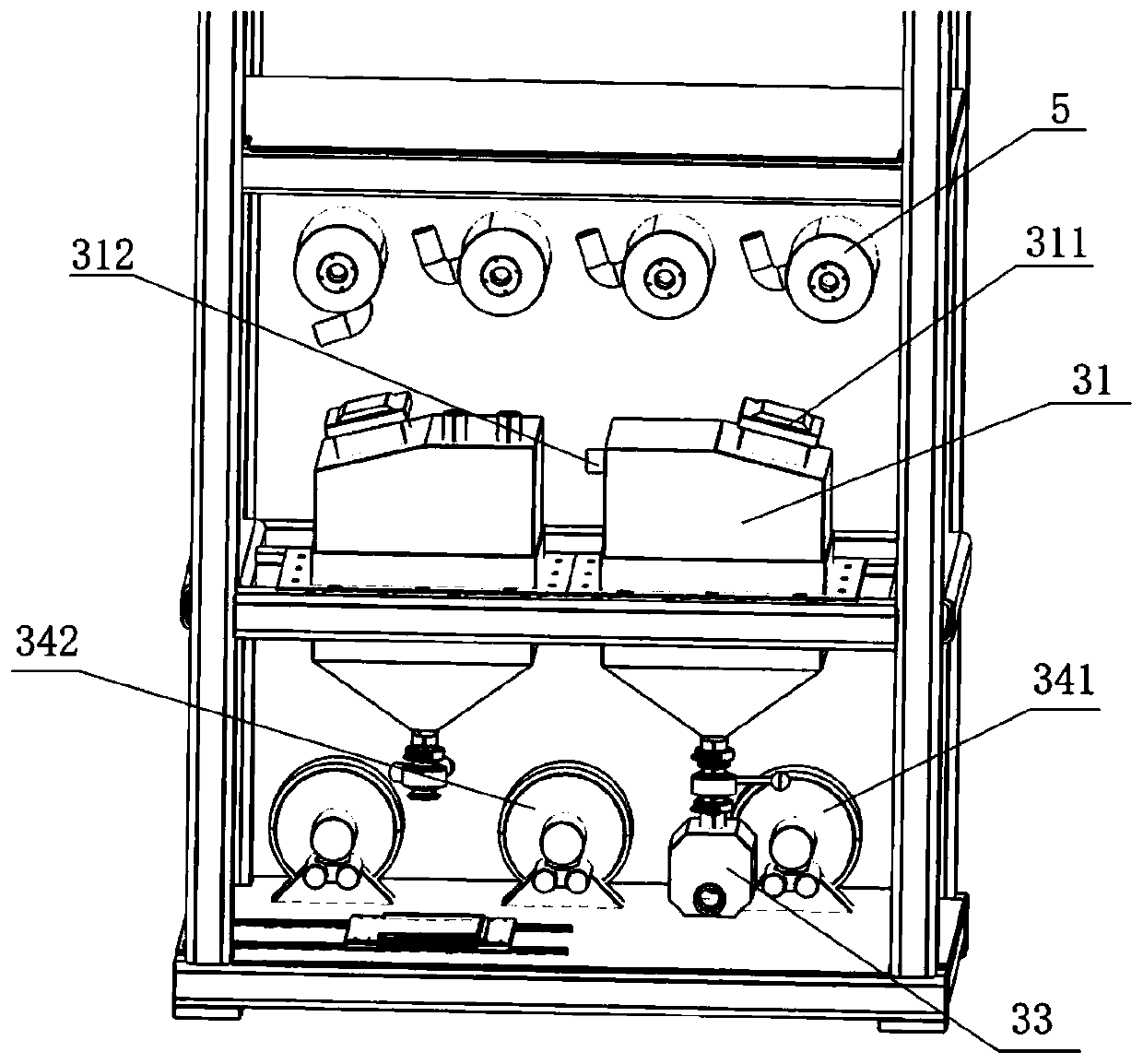

[0044] Such as figure 1 As shown, this embodiment provides a powder management system for SLM equipment, which is used to supply powder to the powder spreading system 6 in the SLM equipment and collect processed powder. The powder management system includes a rack that provides support for the entire system Body 1, powder falling device 2, powder storage and transmission device 3, powder collecting device 4 and powder filtering cavity 5, powder falling device 2 is connected to the upper end of the working area of powder spreading system 6, and powder collecting device 4 is connected to the powder spreading system 6. At the lower end of the working area, the powder storage and transmission device 3 is respectively connected to the powder falling device 2 and the powder collection device 4. The powder storage and transmission device 3 transmits powder through the turbo fan unit 34, and the powder filter chamber 5 is used for the powder management system. The powder in each pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com