Method for solving wave shapes among racks through proportional convexity variation coefficients

A technology of proportional convexity and variation coefficient, which is applied in the direction of contour control, etc., to achieve the effect of reducing roll changing time and reducing roll consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

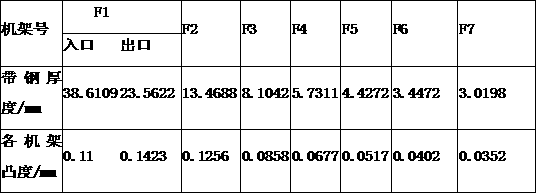

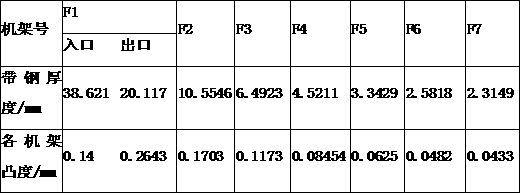

[0038] The method for solving the wave shape between racks through the proportional convexity variation coefficient of the present embodiment includes the following steps:

[0039] (1) Determine the proportional convexity change coefficient Pi of each rack, and the determination method is as follows:

[0040] (101) According to the crown control ability of each stand itself and the position of the stand in the whole unit, the conventional hot continuous rolling finishing mill is composed of 7 rolling stands. 3 racks, that is, F5 to F7 racks are the rear racks;

[0041] (102) The sum of the proportional convexity change coefficients of each rack is 1, that is, P1+P2+P3+P4+P5+P6+P7=1; among them, the proportional convexity change of the front rack is allowed, in order to ensure that the inter-rack board The shape and the outlet of the unit have good straightness, and the proportional convexity change of the rear frame is 0, that is, P5=P6=P7=0;

[0042] (103) In order to deter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com