Processing method of meat compound food and device

A processing method and compound food technology, which is applied in the field of food processing, can solve problems such as the loss of nutrients, condiments and additives that are harmful to health, and unbalanced nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

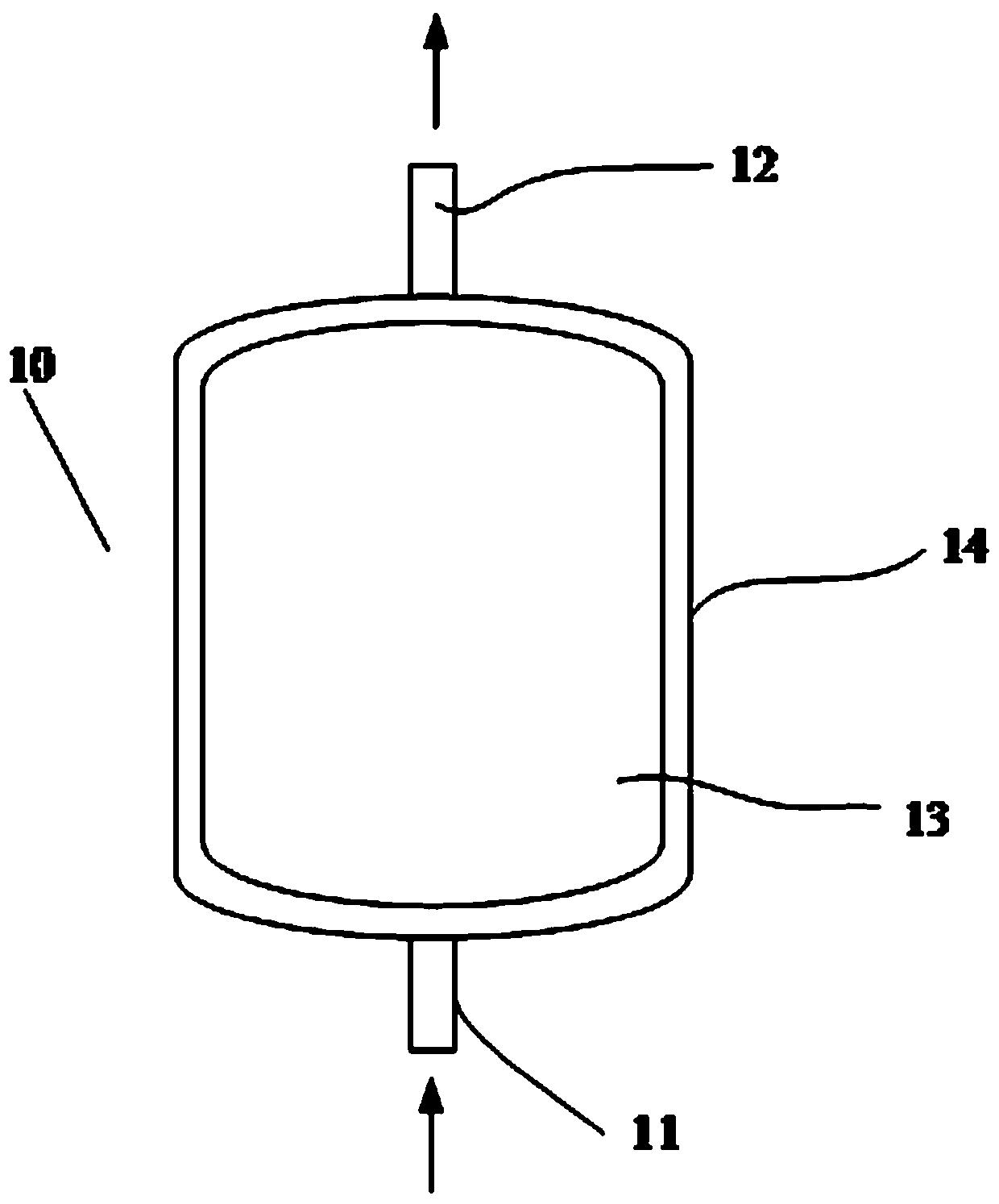

Method used

Image

Examples

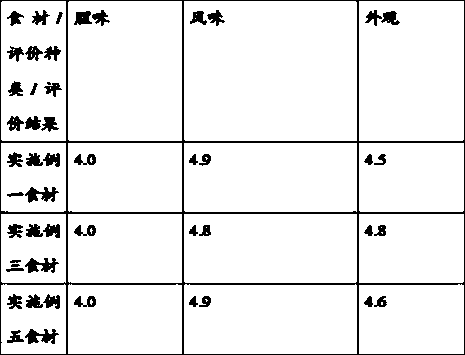

Embodiment 1

[0061] Prepare a total of 10kg of raw materials according to the ingredients in Table 1. Cut the meat ingredients into chunks of about 3cm*3cm*3cm. The carrots in the vegetable ingredients are also cut into chunks or flakes of similar size, and the corn is peeled corn kernels.

[0062] Use the flowing air flow at 90°C with a water content of 780g / kg to process the meat components for 21 minutes. The inflow rate of the flow air flow in the food tank is 100mL / min, and the outflow velocity of the flow air flow is 90 mL / min. Then reduce the humidity of the airflow to 200g / kg, and continue to process for 18 minutes, then add vegetable ingredients, and continue to process for 2 minutes. Finally, raise the temperature of the airflow to 145°C, close the outlet pipe of the food tank, and process for 50 seconds to obtain a pre-finished product; mix chili powder, salt, edible oil, pepper, etc. into the pre-finished product to sterilize the package , and fill the package with the mixed in...

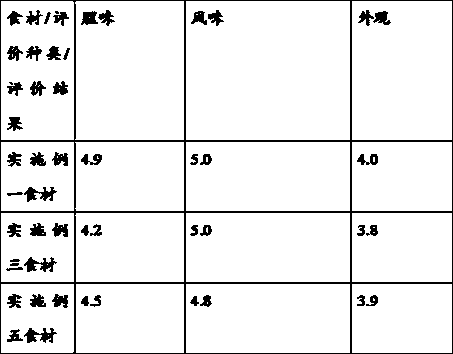

Embodiment 2

[0066] Prepare a total of 10kg of raw materials according to the ingredients in Table 2. Cut the meat ingredients into blocks of about 3cm*3cm*3cm. Among the vegetable ingredients, except corn and peas, the rest are also cut into blocks or flakes of similar size.

[0067] Use the flowing airflow with a water content of 680g / kg at 80°C to process the meat components for 35 minutes. The inflow speed of the flow airflow in the food tank is 100mL / min, and the outflow speed of the flow airflow is 90 mL / min. Then reduce the air humidity to 160g / kg, and continue to process for 33 minutes, then add vegetable ingredients, and continue to process for 2 minutes. Finally, raise the temperature of the airflow to 145°C, close the outlet pipe of the food tank, and process for 50 seconds to obtain a pre-finished product; mix chili powder, salt, edible oil, pepper, etc. into the pre-finished product to sterilize the package , and fill the package with the mixed ingredients of the pre-finished ...

Embodiment 3

[0071] Prepare a total of 10kg of raw materials according to the ingredients in Table 3. Cut the meat ingredients into chunks of about 3cm*3cm*3cm. The vegetable ingredients are tomatoes and sliced. Flammulina velutipes only need to be separated.

[0072] Use the flowing air flow at 80°C with a water content of 600g / kg to process the meat components for 20 minutes. The inflow rate of the flow air flow in the food tank is 100mL / min, and the outflow velocity of the flow air flow is 90 mL / min. Then reduce the air humidity to 190g / kg, and continue to process for 19 minutes, then add vegetable ingredients, and continue to process for 1 minute. Finally, raise the temperature of the airflow to 145°C, close the outlet pipe of the food tank, and process for 30 seconds to obtain the pre-finished product; mix the seasonings such as chili powder, salt, edible oil, pepper, etc. into the pre-finished product, and sterilize the package , and fill the package with the mixed ingredients of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com