Method for cultivating moss

A cultivation method and moss technology, applied in the field of moss cultivation, can solve the problems of unstable properties, single growth environment, low moss proliferation rate, etc., and achieve the effect of improving stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention proposes a kind of cultivation method of moss, comprises the following steps:

[0026] 1): Wash the moss seedlings in clean water to remove the dirt and sand, screen out the mixed impurities, and then sterilize them in 5000 times potassium permanganate solution for 5 minutes, rinse them twice with clean water to remove permanganate Potassium residues, then use a dehydrator to remove excess water and crush them into 0.5cm-long broken stems for later use. When long-term storage is required, first dry the broken stems in the shade;

[0027] 2): Sow the moss seedlings treated in 1) evenly on the surface of the planting blanket, place the sown planting blanket in the moss cultivation room for cultivation, control the light intensity at 5000LUX, and cultivate at 15°C. Water the seedlings, keep the humidity in the planting room at 80%, and add specially prepared water and fertilizer to the leaves once a week;

[0028] 3): After drying the moss stems with...

Embodiment 2

[0033] The present invention proposes a kind of cultivation method of moss, comprises the following steps:

[0034] 1): Wash the moss seedlings in clean water to remove the dirt and sand, screen out the mixed impurities, and then sterilize them in 5000 times potassium permanganate solution for 5 minutes, rinse them twice with clean water to remove permanganate Potassium residues, then use a dehydrator to remove excess water and crush them into 0.5cm-long broken stems for later use. When long-term storage is required, first dry the broken stems in the shade;

[0035] 2): Sow the moss seedlings treated in 1) evenly on the surface of the planting blanket, place the sown planting blanket in the moss cultivation room for cultivation, control the light intensity at 5000LUX, and cultivate at 15°C. Water the seedlings, keep the humidity in the planting room at 80%, and add specially prepared water and fertilizer to the leaves once a week;

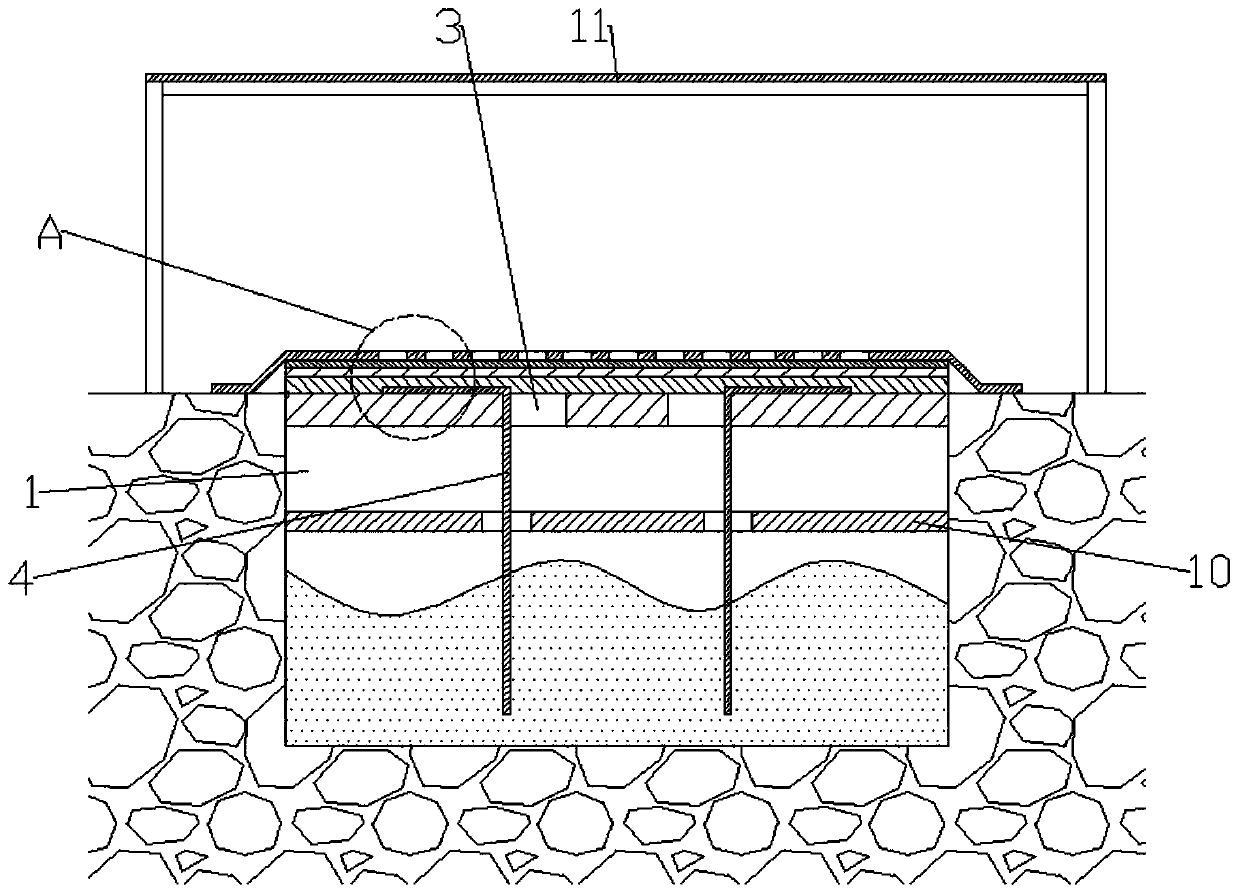

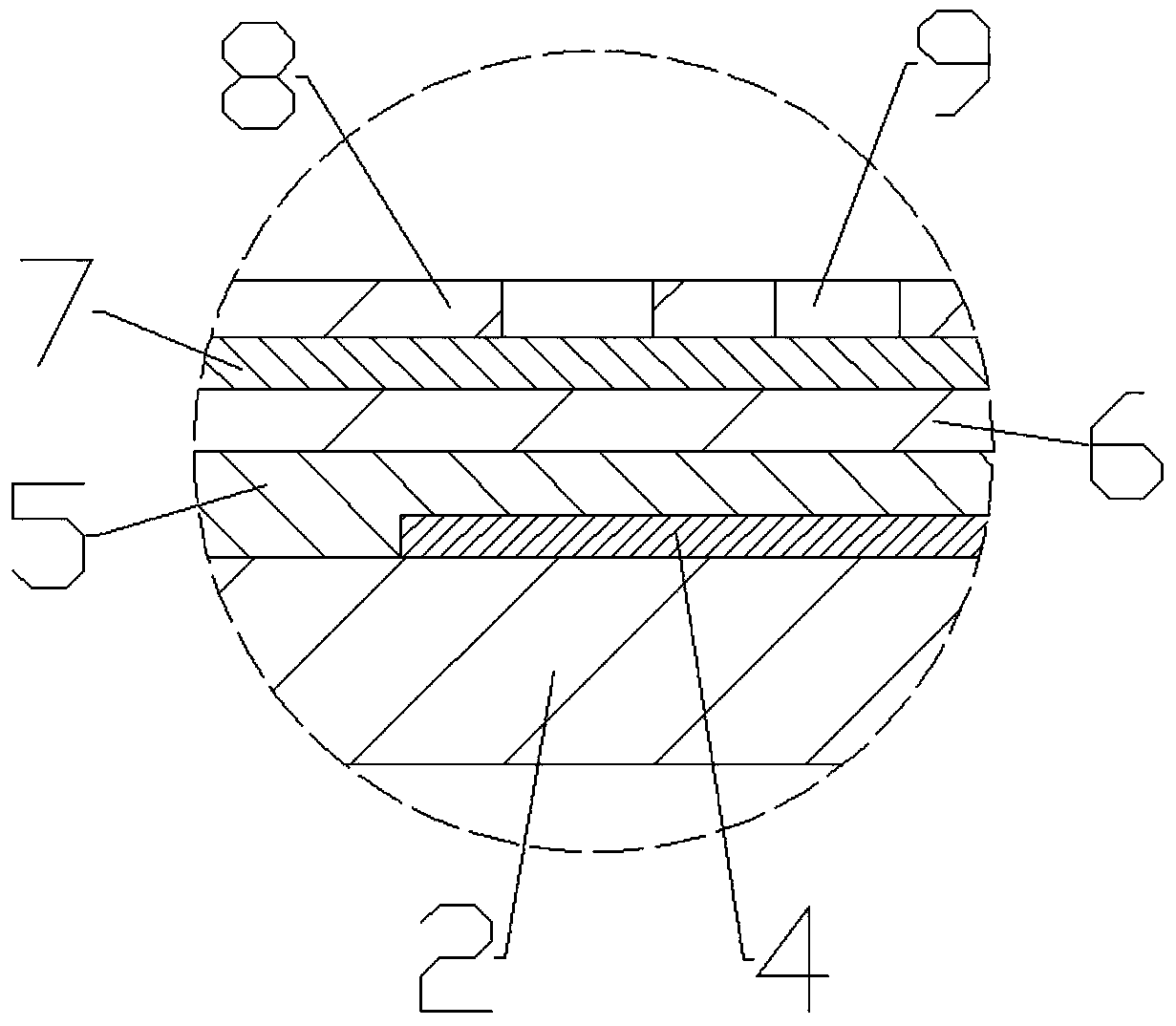

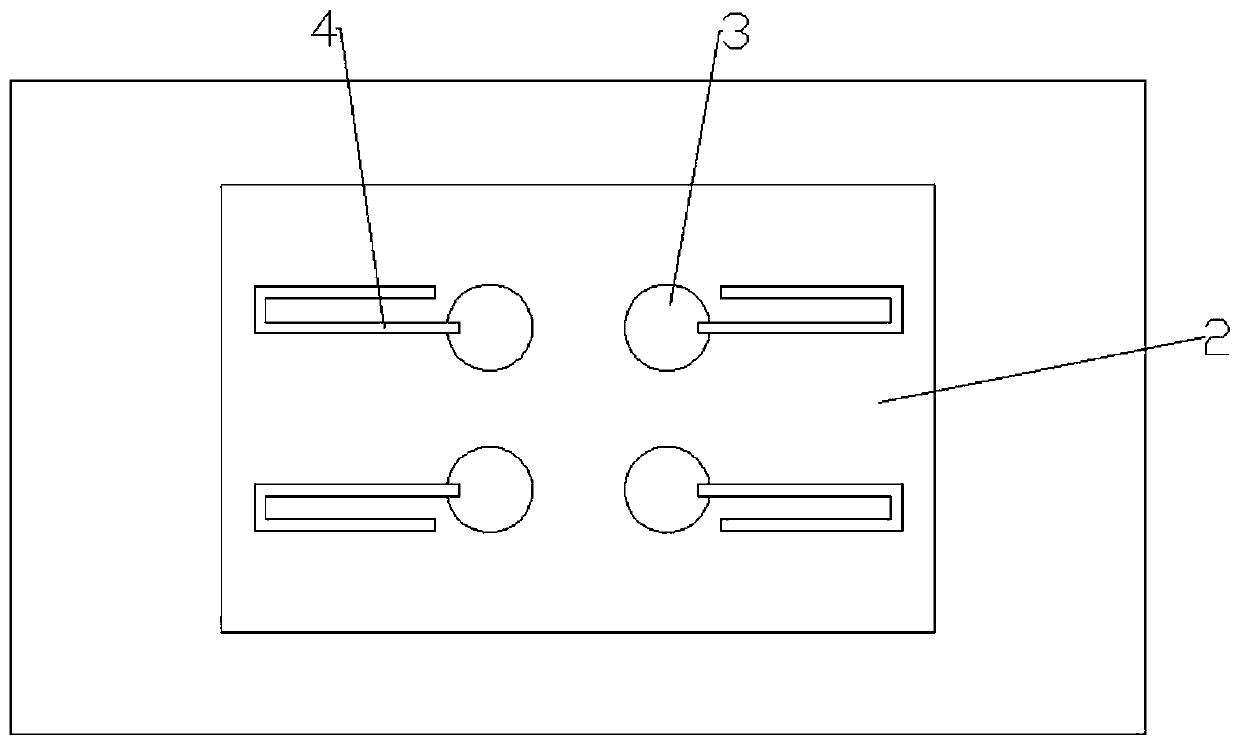

[0036] 3): Make a replenishable water stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com