A fully automatic grain bagging and packaging equipment

A fully automatic, grain technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of inability to achieve automatic bagging and filling of woven bags, grain pressing, etc., and achieve good packaging efficiency, high filling efficiency, Cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

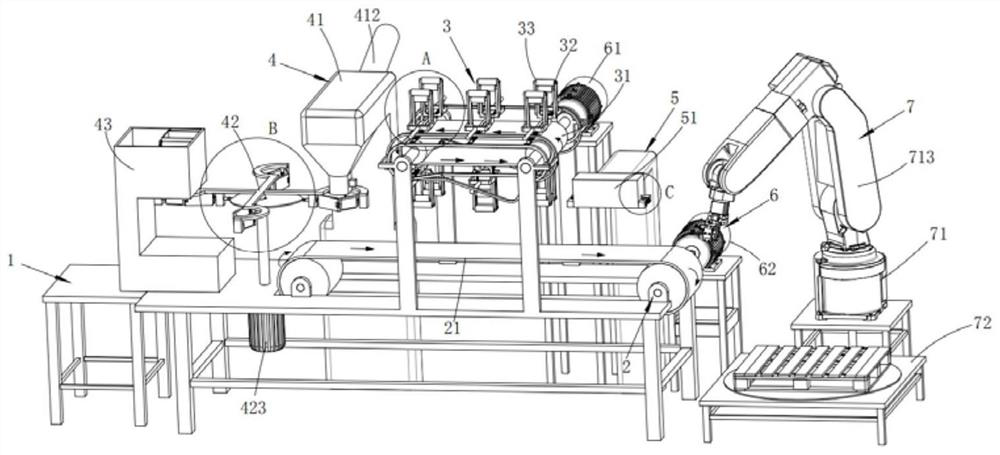

[0049] Such as Figure 1 to Figure 4 As shown, a fully automatic grain bagging and packaging equipment includes:

[0050] Mounting station 1;

[0051] A transport device 2, the transport device 2 includes a transport assembly a21, and the transport assembly a21 is installed on the installation platform 1;

[0052] Compression device 3, the compression device 3 includes a transportation component b31, a closing component 32 and a pressing component 33, the transportation component b31 is installed on the installation platform 1, and it is located above the transportation component a21; the closing The components 32 are arrayed on the transport component b31 along the movement path of the transport component b31; the pressing component 33 is provided in one-to-one correspondence with the closing component 32, and the closing component 32 is slidably arranged on the pressing component 33 end of

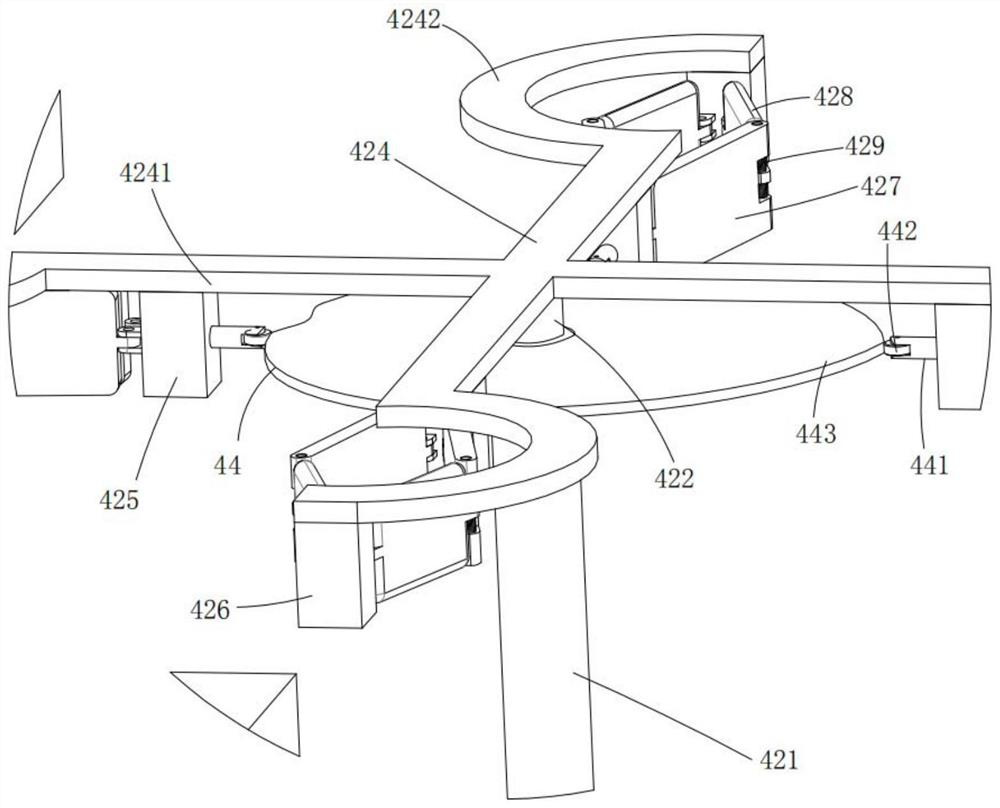

[0053] The feeding device 4, the feeding device 4 includes a feeding assembly 41,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com