Cr ion doped Mn3O4 thermocatalytic material, and preparation method and application thereof

An ion doping and thermal catalysis technology is applied in the field of Cr ion doped Mn3O4 thermocatalytic material and its preparation, which can solve the problems of low photocatalytic utilization rate and small light response range, and achieves improved thermal catalytic activity and cheap and easy raw materials. easy to transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

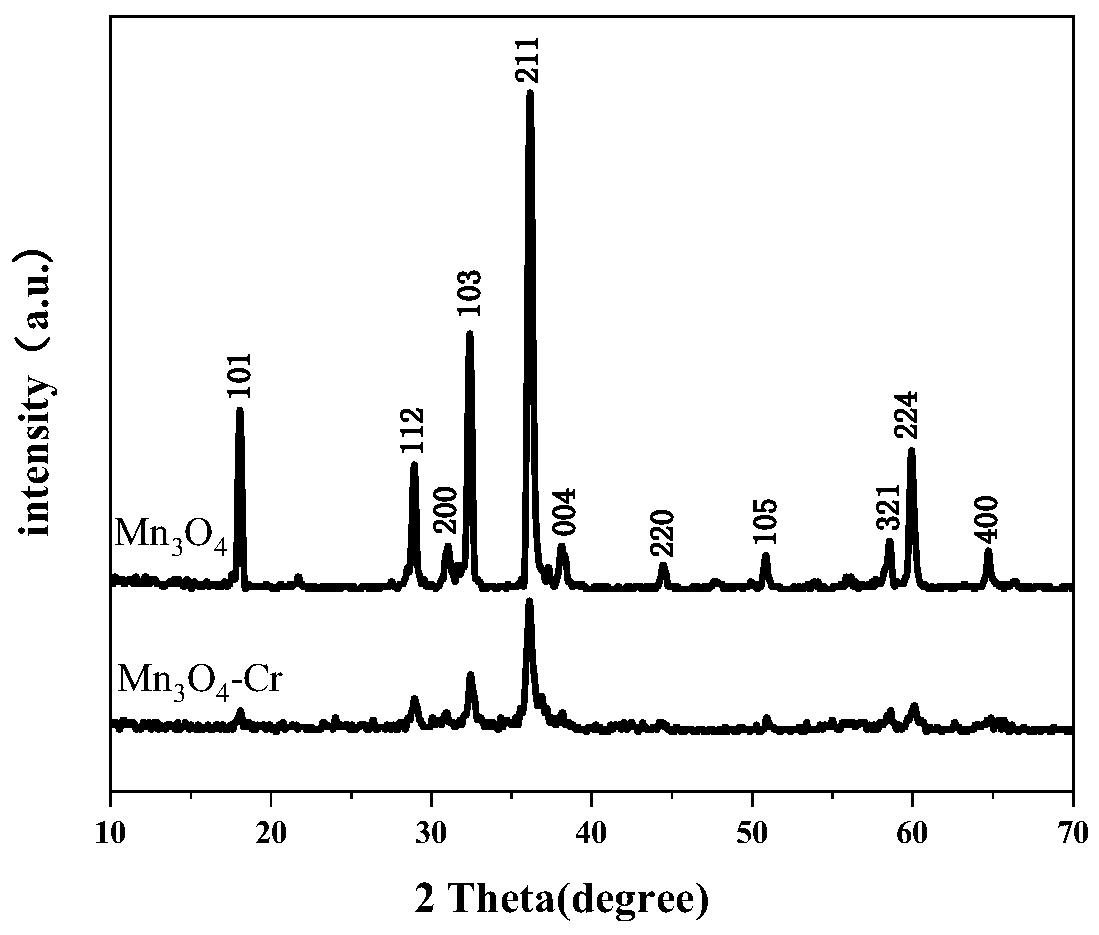

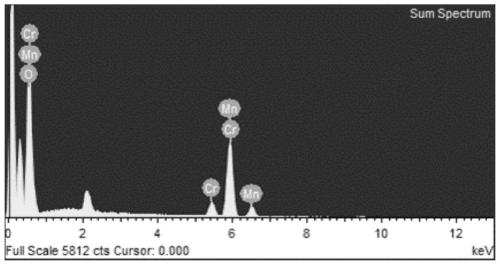

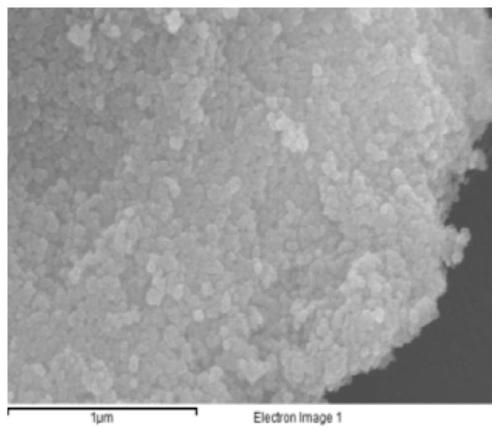

[0031] (1) Cr ion-doped Mn 3 o 4 Thermocatalytic material Cr-Mn 3 o 4

[0032] The preparation method is as follows:

[0033] 1) Add 2.86g of 50% manganese nitrate into a beaker filled with 10ml of deionized water, and stir for 15min to fully dissolve it;

[0034] 2) Add 0.64g of sodium hydroxide into a beaker of 10ml of deionized water, stir for 15min to fully dissolve;

[0035] 3) Add 1.28g chromium nitrate nonahydrate (the molar weight of Cr is 10% of the molar weight of Mn) into the manganese salt solution obtained in step 1), and mix it uniformly by ultrasonic;

[0036] 4) Drop the mixed solution obtained in step 3) into the sodium hydroxide solution, and sonicate for 30 minutes until the solution is evenly mixed;

[0037] 5) Place the solution obtained in step 4) in a centrifuge, and obtain a precipitate after centrifugation.

[0038] 6) Place the mixed solution obtained in step 5) in an oven, dry at 60°C, and cool naturally to obtain the precursor;

[0039] 7) G...

Embodiment 2

[0044] Example 2 Application

[0045] (1) Effects of different catalytic materials on the catalytic degradation rate of isopropanol at different temperatures

[0046] The test process is: get the pure Mn prepared by 0.1g example 1 respectively 3 o 4 and 10% Cr doping amount prepared Cr-Mn 3 o 4 Thermal catalysis was respectively loaded into a quartz flow reactor, and then the reactor was placed in a constant temperature box, and then connected with flowing isopropanol, and the flow rate was adjusted to 1.37ml / s. The thermocatalytic degradation of isopropanol was carried out at different temperatures under dark conditions, and the peak areas of degraded isopropanol and initial isopropanol were recorded. Get the amount of degraded isopropanol through calculation, and the amount of initial isopropanol, such as image 3 Shown, the Cr ion-doped Cr-Mn of the present invention 3 o 4 The thermocatalytic degradation rate of the composite thermocatalytic material is higher than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com