A pressure sensor calibration system for water level measurement in aquaculture ponds

A technology for water level measurement and calibration system, which is used in test/calibration devices, measurement devices, liquid/fluid solid measurement, etc., and can solve problems such as poor measurement data, affecting the measurement effect of the sensor head, and the inclination of the sensor head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] as attached figure 1 to attach Image 6 Shown:

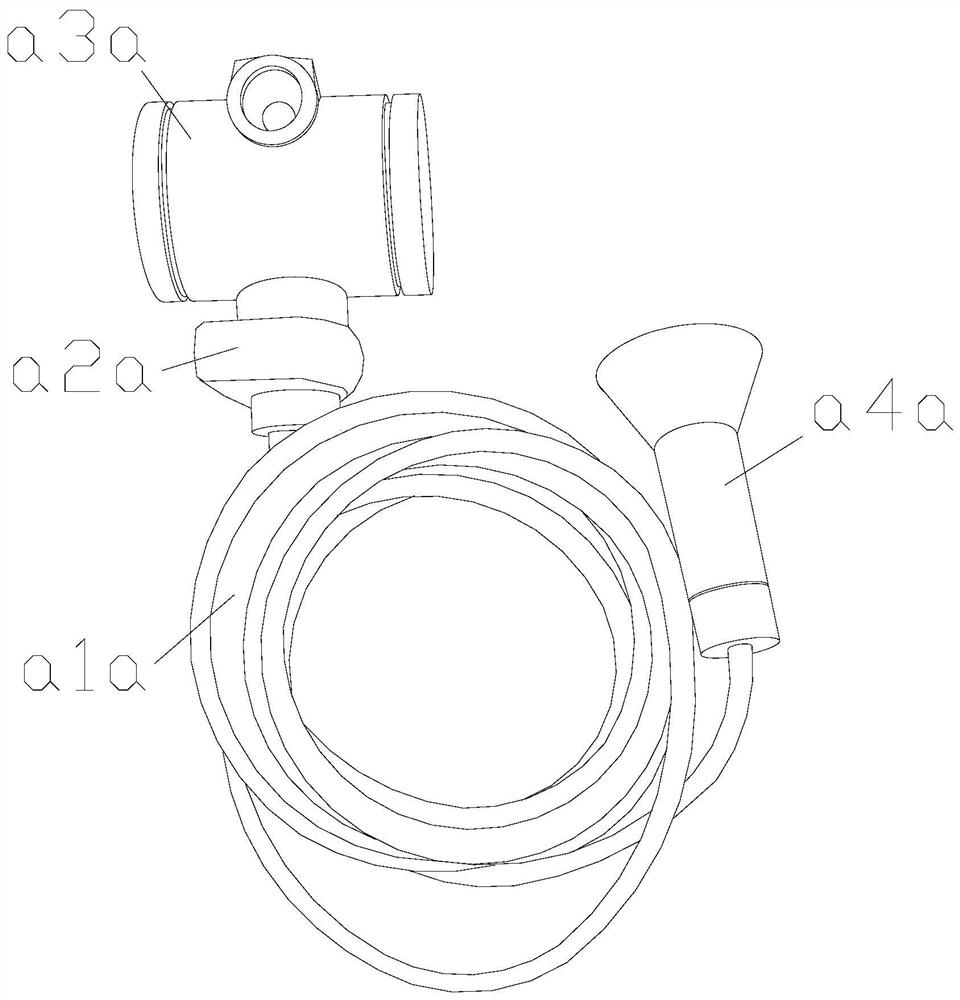

[0035] The invention provides a pressure sensor calibration system for water level measurement in a culture pond, the structure of which includes a conduction line a1a, an expansion joint a2a, a PLC programmable control terminal a3a, and a sensor probe a4a.

[0036] The conductive line a1a is connected to the expansion joint a2a, and the expansion joint a2a is installed on the outer surface of the PLC programmable control terminal a3a, and the end of the conductive line a1a away from the expansion joint a2a is connected to the sensor head a4a.

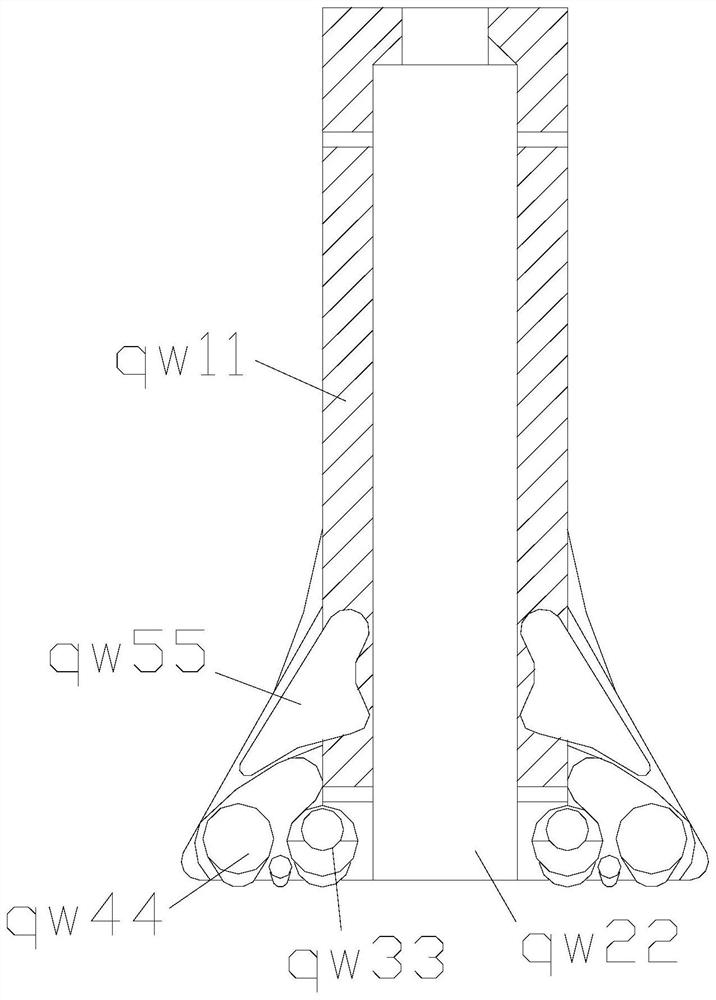

[0037] The sensing head a4a includes an outer limiting shell qw11, an inner channel qw22, a semi-floating body qw33, a stable fork angle qw44, and an inner brace angle qw55. Installed inside the outer limiting shell qw11, the semi-floating body qw33 is arranged on the side of the stable prong qw44.

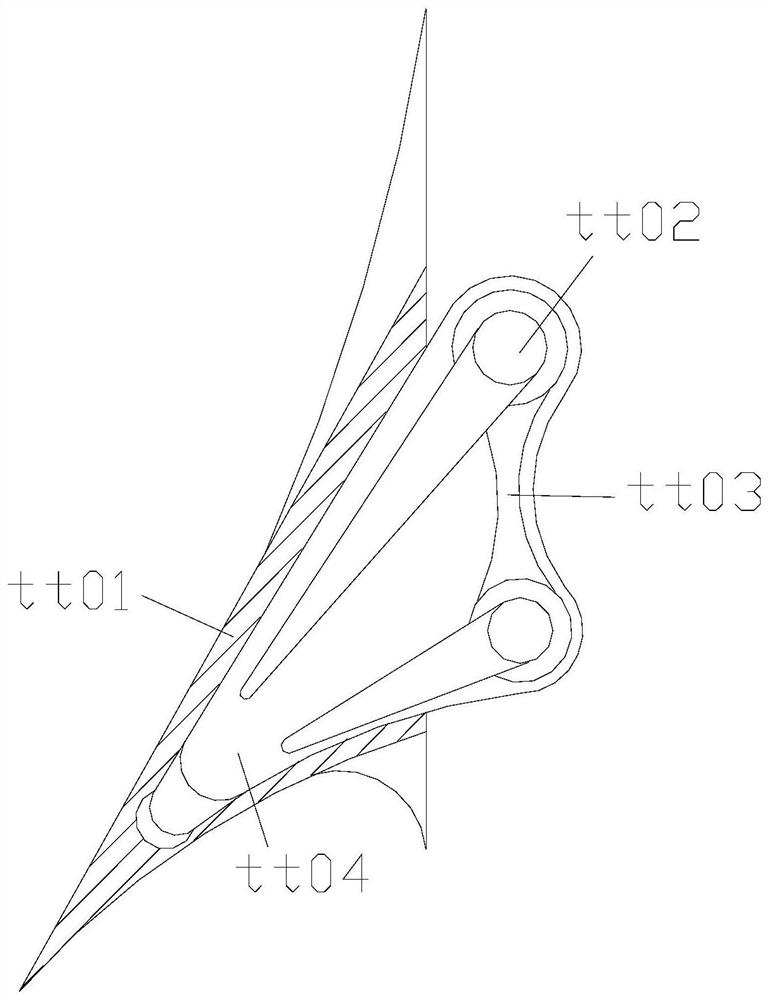

[0038] Wherein, the inner bracing angle qw55 includes an outer pocket tt01, a ...

Embodiment 2

[0045] as attached Figure 7 to attach Figure 9 Shown:

[0046] Wherein, the semi-floating body qw33 includes a vertical ball c10, a buffer layer c20, an inner buoy c30, and a buoyant strip c40, the buffer layer c20 is attached to the outer surface of the vertical ball c10, and the inner buoy c30 is installed on the buffer layer Inside c20, under the buffer layer c20, there is an anti-floating bar c40. The anti-floating bar c40 is in an arc-shaped structure. The vertical ball c10 is a spherical structure. The vertical ball c10 gives a certain gravity to the whole. Extending the area of the connecting parts, the inner buoyancy opening c30 makes the whole have a certain buoyancy, and the buoyancy bar c40 assists the force given by the outer layer to form buoyancy.

[0047] Wherein, the anti-floating strip c40 includes a uniform floating body h11, an outer soft strip h22, an auxiliary buoyancy arc h33, and a movable support bar h44. The uniform floating body h11 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com