Foam floating bridge rapidly connected through buckling teeth

A quick connection and pontoon technology, applied to pontoon bridges, bridges, bridge parts, etc., can solve the problems of unfavorable ecological dredging work, low connection strength, inconvenient dismantling, etc., to improve splicing process, improve floating ability, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

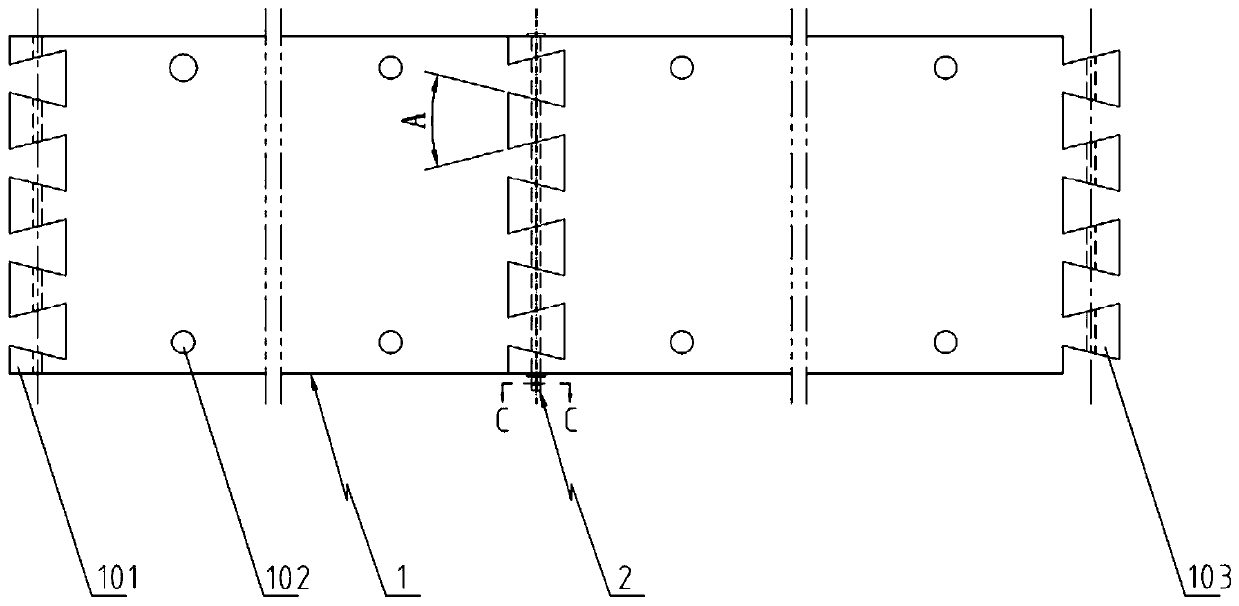

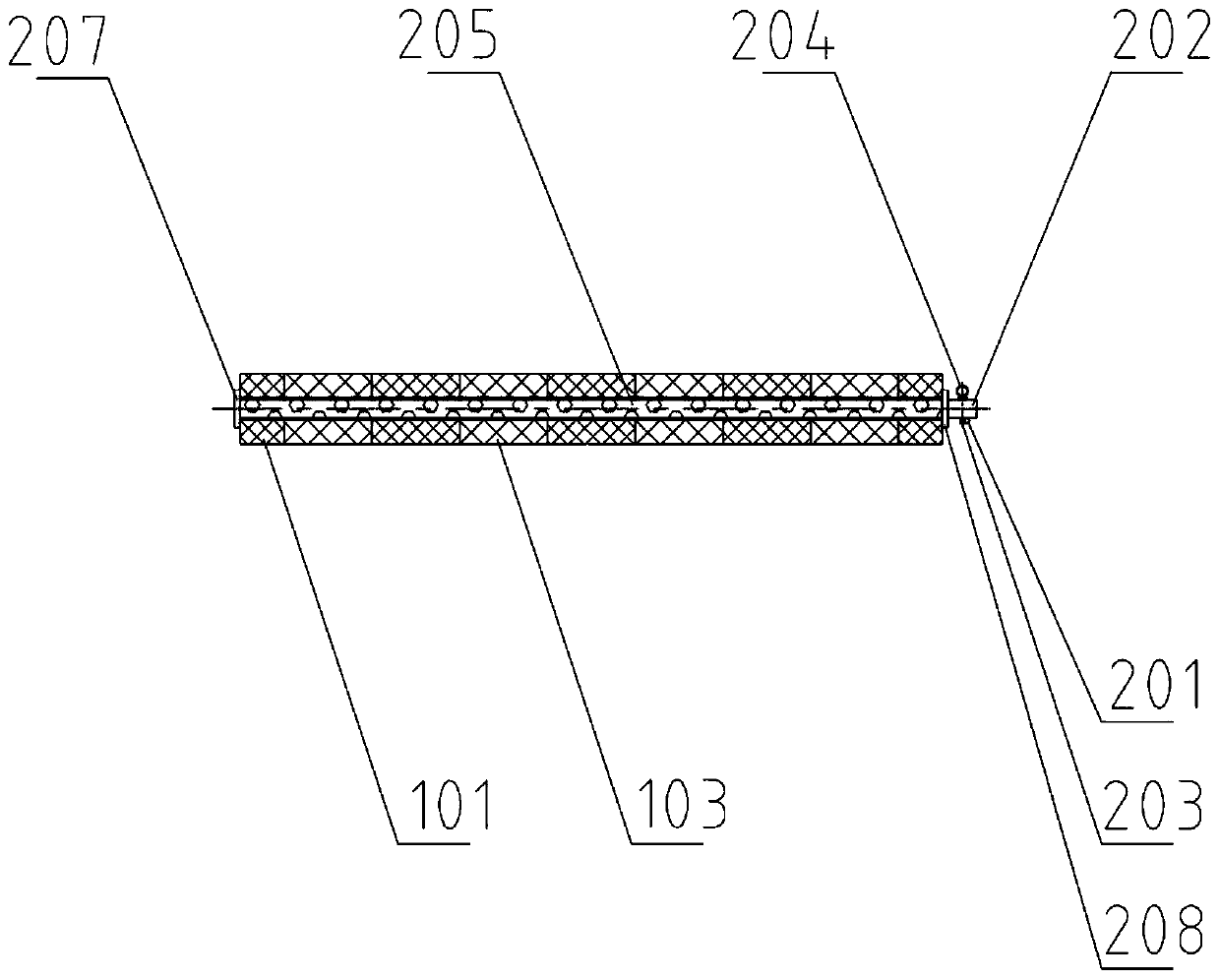

[0034] Such as Figure 1~3 As shown, the present invention includes a bridge plate 1, the bridge plate 1 is a rectangular plate-shaped structure, several positioning holes 102 are vertically evenly distributed on the bridge plate 1, and several grooves are equally spaced along the side edge of the bridge plate 1. The groove separates the edge to form several protruding first-type teeth, and the first-type teeth together form a first-type buckle 101. Several protruding second-type teeth are arranged, and the outline of each second-type tooth is the same as the groove. The second-type teeth together form the second-type buckle 103, and the two adjacent bridge plates 1 pass through the first-type buckle 101 Fastened with the second-type buckle teeth 103, several bridge plates 1 are connected in series to form a pontoon structure by buckling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com