Full-automatic road marked line scribing machine

A road marking and marking machine technology, which is applied to roads, roads, road repair and other directions, can solve the problem of inability to accurately control the interval time of marking machines, and achieve the effect of high marking efficiency, labor saving and easy placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

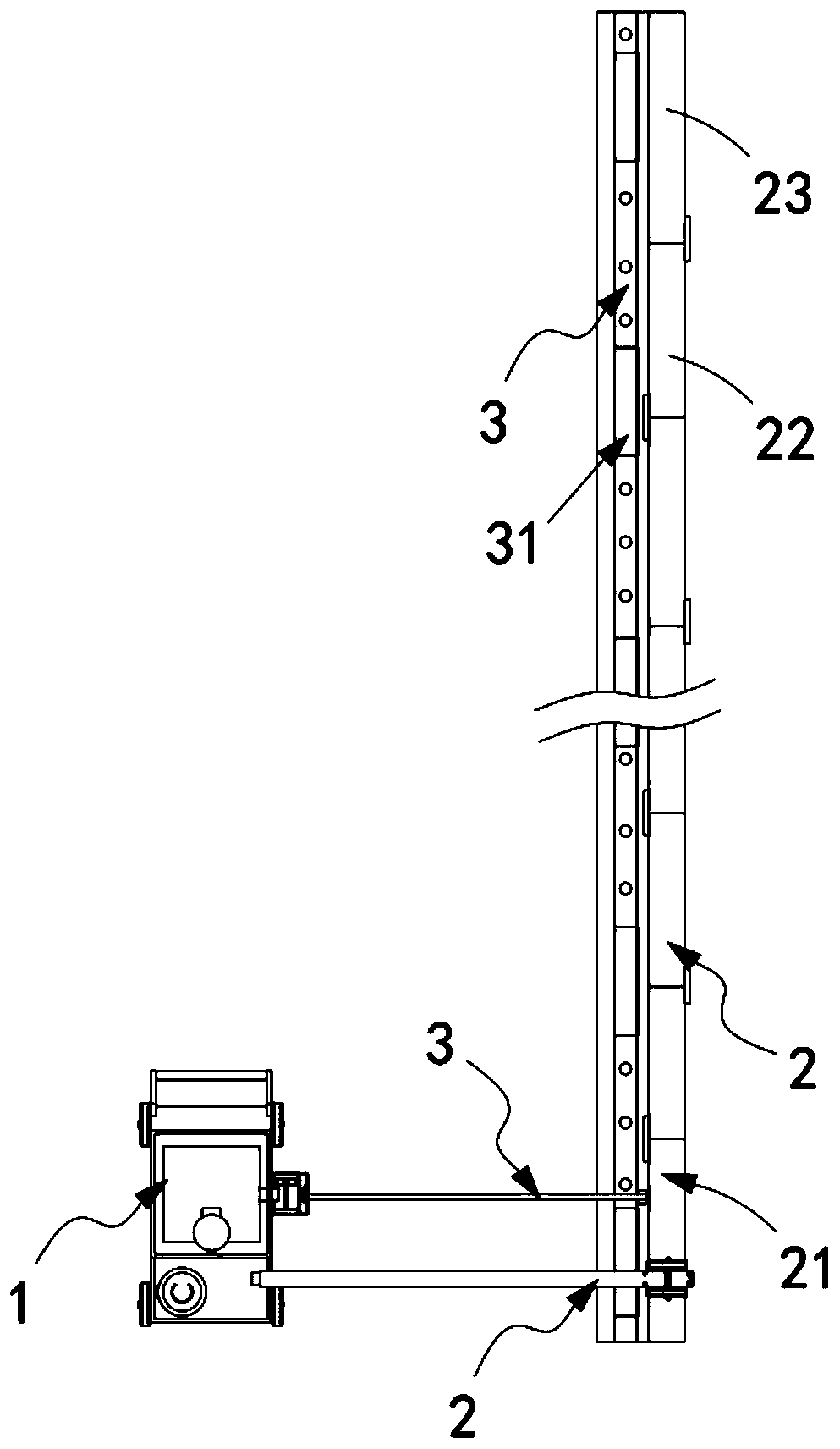

[0043] Such as figure 1 As shown, a fully automatic road marking marking machine includes a marking machine 1, and also includes:

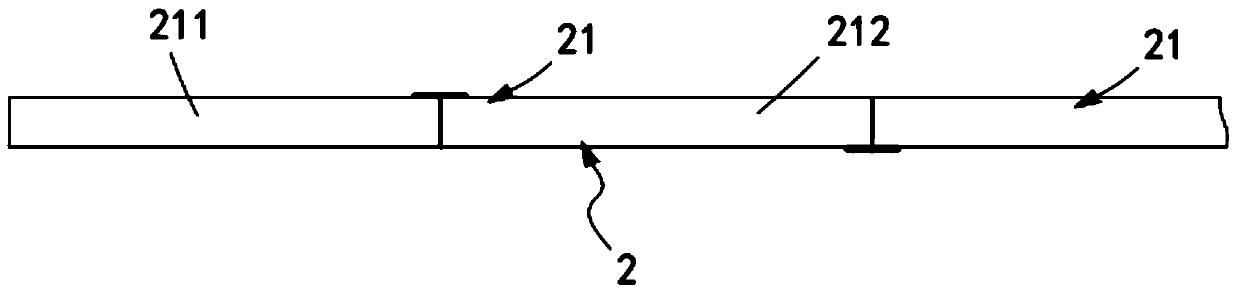

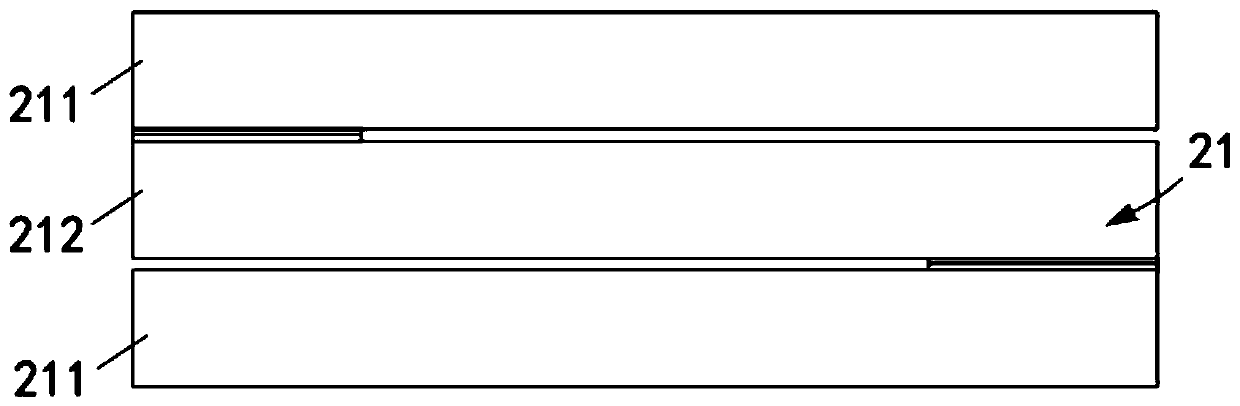

[0044] Limiting mechanism 2, said limiting mechanism 2 is composed of several groups of guide units 21;

[0045] A control mechanism 3, which includes a protrusion assembly 31 detachably mounted on the limit mechanism 2;

[0046] A first transmission mechanism 4, the first transmission mechanism 4 is connected to the marking machine 1 and matched and slides on the limit mechanism 2; and

[0047] The second transmission mechanism 5 is arranged in connection with the marking machine 1 and cooperates with the control mechanism 3 to control the opening and closing of the discharge valve of the marking machine 1.

[0048] In the traditional virtual line marking work, a manual cart is required and the switch of the marking machine is controlled according to the prior marking.

[0049] In this embodiment, by setting the first transmission mechanism and the limit me...

Embodiment 2

[0071] Such as Figure 8 , Picture 9 with Picture 10 As shown, the components that are the same as or corresponding to those in the first embodiment use the reference numerals corresponding to those in the first embodiment. For simplicity, only the differences from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

[0072] Further, such as Picture 9 As shown, the extension end of the sliding portion 52 is provided with a buffer seat 53.

[0073] In this embodiment, the buffer seat 53 is provided so that when the transmission rod 51 is located on the base 27, that is, when the valve is closed, the transmission rod 51 is balanced by both ends of the marking machine and the buffer seat 53 to achieve a pressing effect.

[0074] work process:

[0075] First, according to the actual road conditions, the limit mechanism 2 is unfolded and fixed, and then the protrusion assembly 31 is inserted on the base 27 according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com