Continuous plant extraction machine

An extraction machine and plant technology, applied in solid solvent extraction, presses, material molding presses, etc., can solve problems such as poor economic benefits, time-consuming and labor-intensive work, troublesome operations, etc., to achieve improved extraction rate and low construction cost , the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

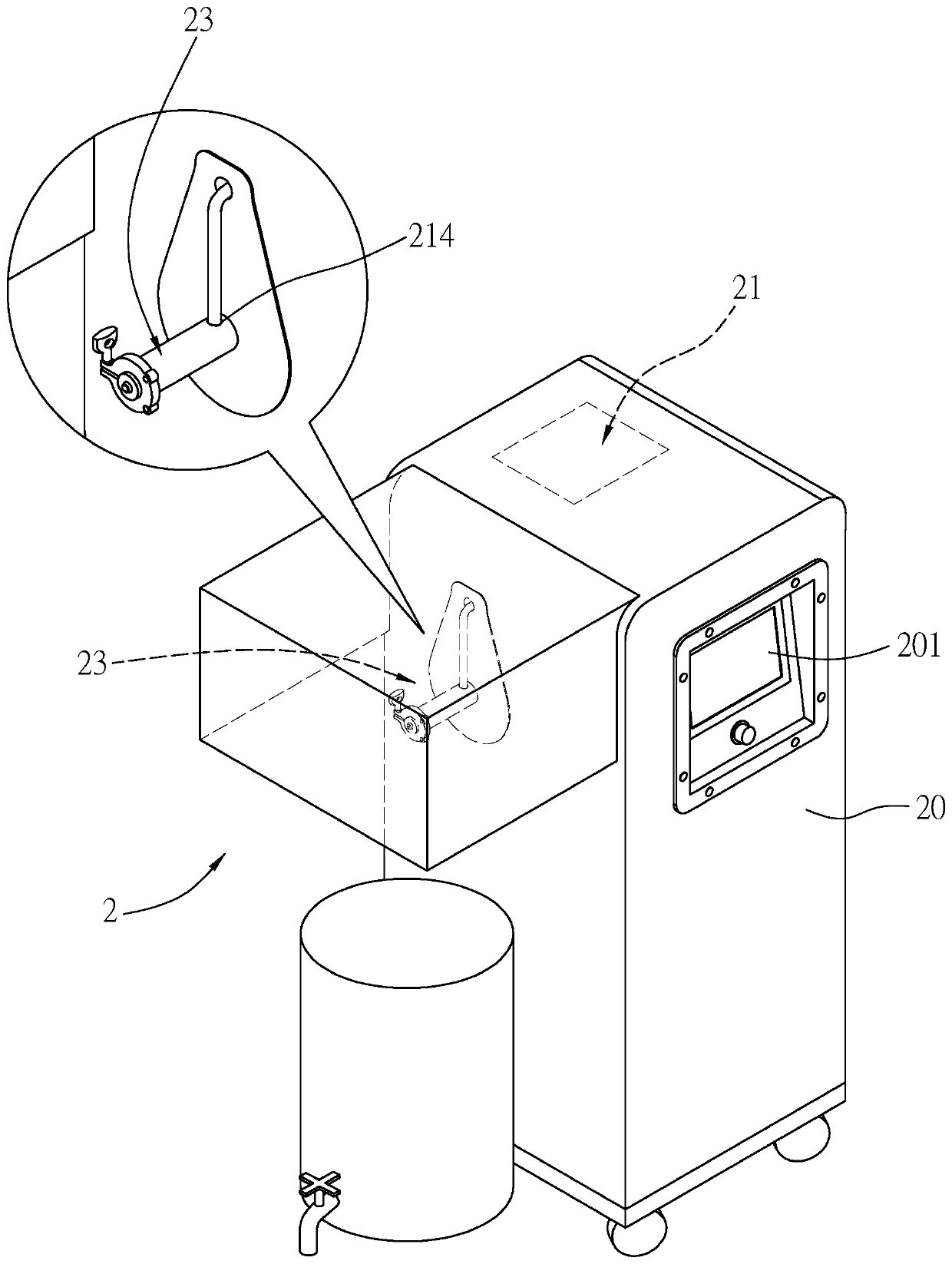

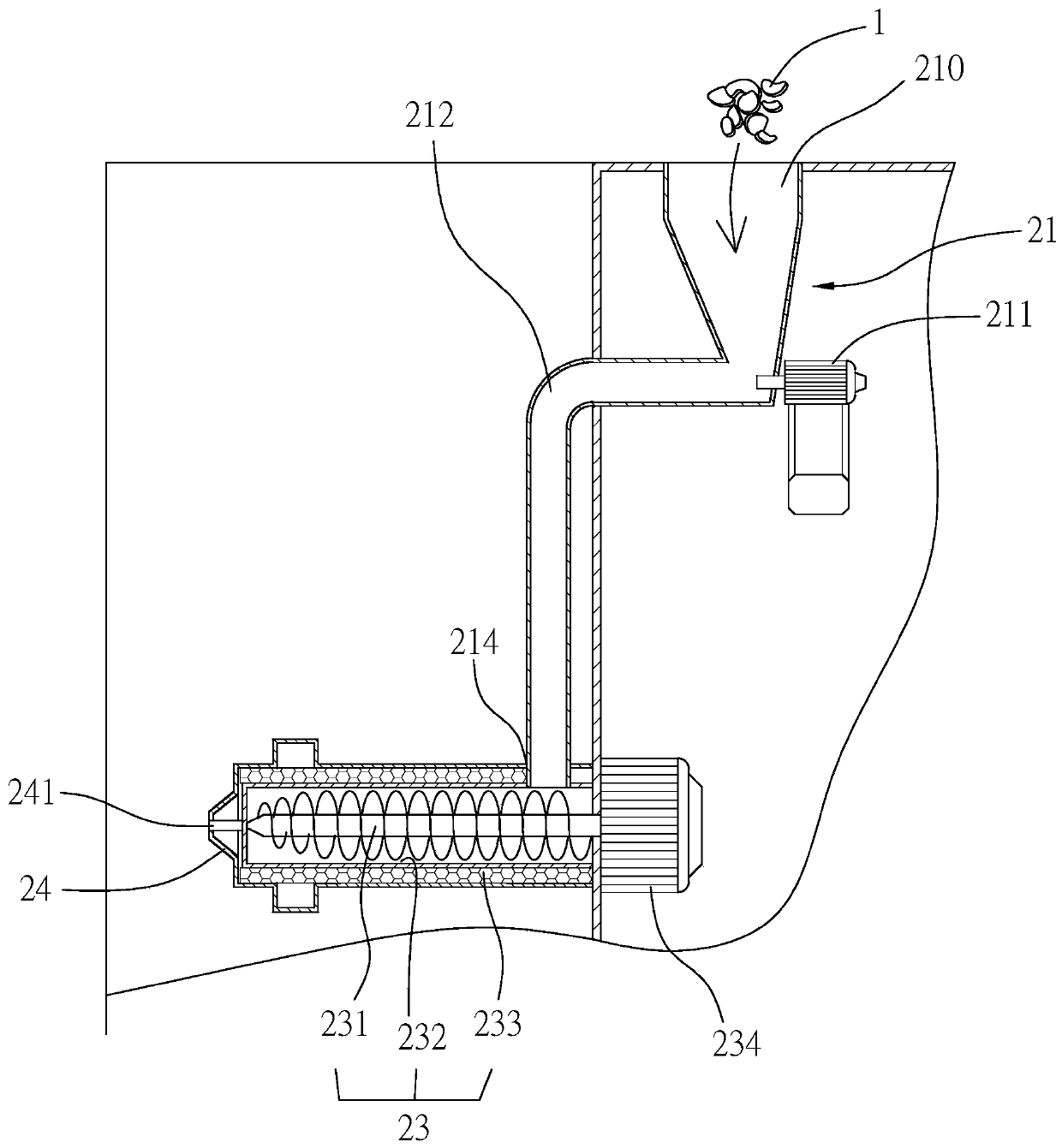

[0027] First of all, the present invention is a machine for extracting plant raw materials, including: turmeric, algae, red yeast rice, mushrooms, fungi or beans... and other plants are suitable, and even the peels or plant by-products after eating plant fruits can be extracted. The product is recovered, reprocessed and extracted to make a new product. The plant by-products are: citrus peels, pomelo peels, etc., and this embodiment uses seaweed raw material 1 as an illustration. Please refer to figure 1 Shown is the flow chart of seaweed raw material extraction in the present invention. Seaweed raw material 1 is first put into extractor 2. In this embodiment, kelp is used as a sample, and seaweed raw material 1 is dropped into sleeve 232 through feed pipe 212, namely The screw shaft pushes 2311 and the heating element heats 2331, so that the seaweed raw material 1 is rubbed and crushed in the sleeve 232, so that the seaweed raw material 1 is crushed and melted into a thick shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com