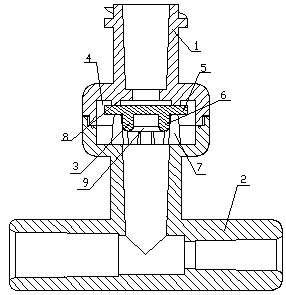

Check valve of infusion pump

A one-way valve and infusion pump technology, applied in the field of infusion pump supporting products, can solve problems such as increasing the difficulty of doctors' work, and achieve the effects of simple structure, prevention of reverse leakage, and convenient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A one-way valve for an infusion pump. The one-way valve includes a valve body upper cover 1, a valve body lower cover 2 and a valve core 3. The valve body upper cover 1 is fixedly connected to the upper part of the valve body lower cover 2. The connecting part of the valve body upper cover 1 and the valve body lower cover 2 forms an infusion cavity 4, and the valve core 3 is arranged in the infusion cavity 4, and the valve core 3 includes a circular The pressure piece 5 and several push rods 6 fixedly connected to the lower part of the circular pressure piece 5, the circular pressure piece 5 and the several push rods 6 are of an integrated silicone structure, and the upper part of the infusion lumen 4 communicates with the valve In the body upper cover 1, the lower part of the infusion inner cavity 4 is connected to the valve body lower cover 2, the valve body upper cover 1 and the valve body lower cover 2 are tapered inside, and the infusion inner cavity 4 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com