Clamping and positioning device for ring-sleeve parts and processing method for ring-sleeve parts

A positioning device and parts processing technology, which is applied in the direction of metal processing equipment, manufacturing tools, turning equipment, etc., can solve the problems of reducing the processing accuracy of ring sleeve parts, the processing efficiency needs to be improved, and the number of clamping times is large, etc., to achieve shape and position tolerances Good, avoid errors, improve the effect of turning precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

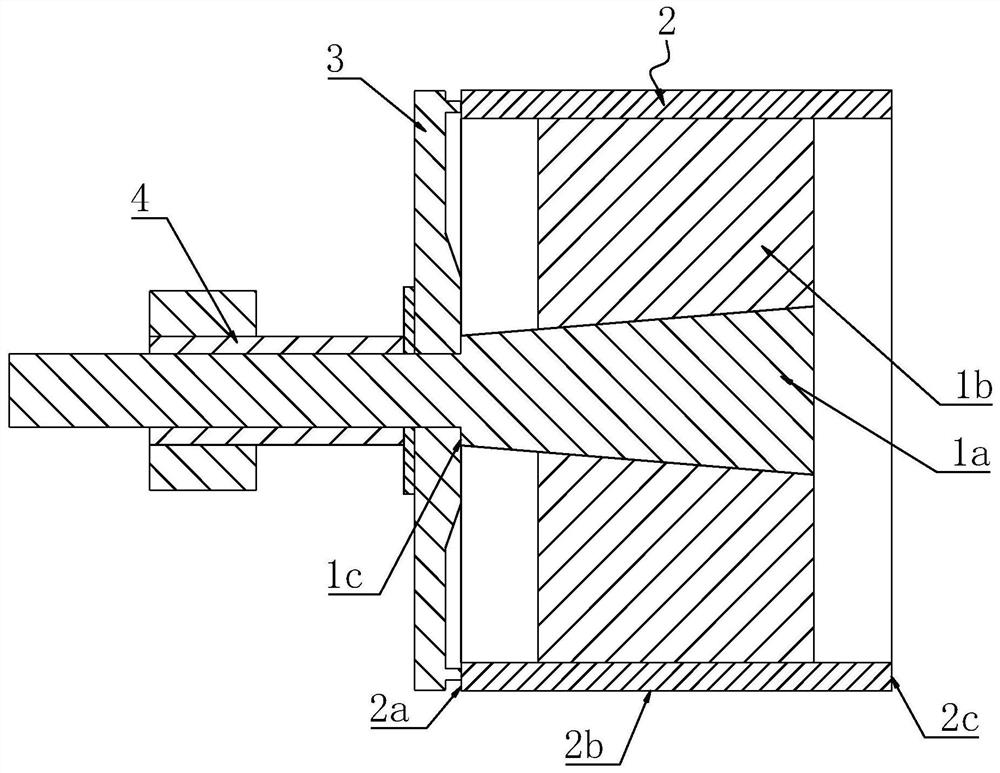

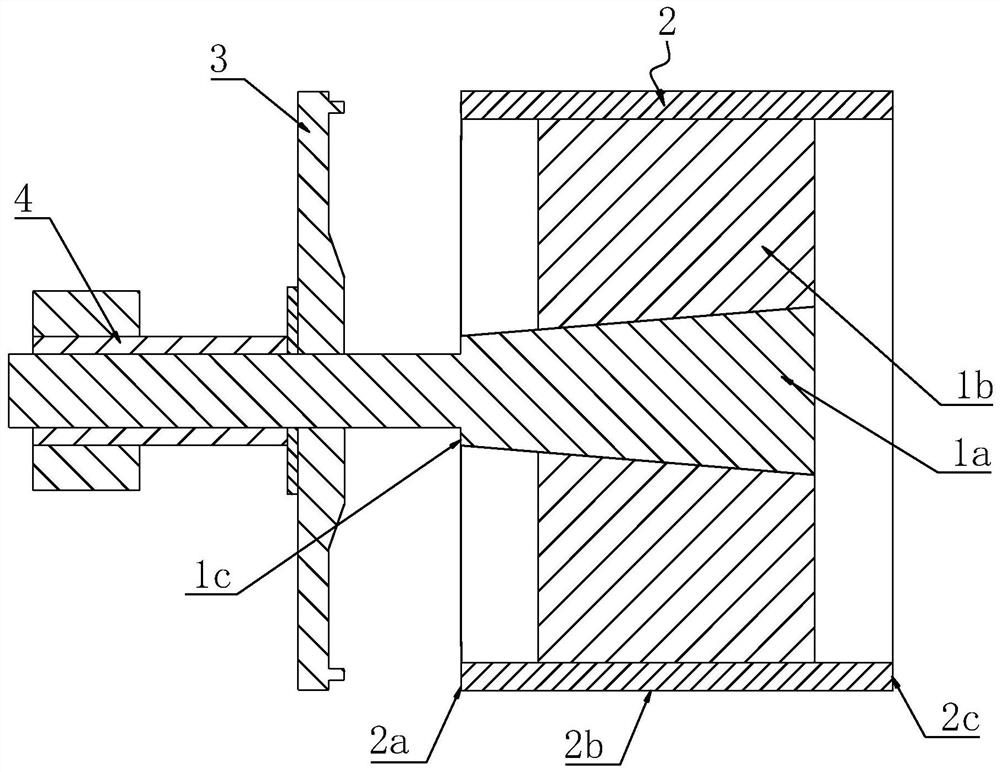

[0027] Such as figure 1 and 2 As shown, a clamping and positioning device for ring sleeve parts, its main structure includes a support shaft 1a that rotates coaxially with the main shaft of the machine tool, and an inner stretching fixture 1b arranged at the end of the support shaft 1a, the inner stretching fixture 1b is used On the wall of the inner hole of the clamping part 2, a positioning mechanism 3 is installed on the support shaft 1a in a movably connected manner for positioning the end surface I2a of the supporting part 2.

[0028] A method for processing ring-type parts. This embodiment takes the processing of part 2 internal ring gear in the planetary gear train as an example. Part 2 has a central inner hole, and the two ends of the central inner hole have end faces I2a and end faces II2c respectively. The area to be processed includes: the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com