A medium-voltage fire-resistant power cable

A power cable and fire-resistant technology, which is applied in the direction of power cables, power cables with shielding layers/conductive layers, insulated cables, etc., can solve problems such as single structure, inability to solve high-temperature combustion, and inability to control fires in time to prevent fire from expanding , Good cooling effect

Active Publication Date: 2022-05-31

上海业燊科技有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing power cable has a single structure, which can only simply isolate the external high temperature or external combustion, and cannot solve the combustion caused by the internal short circuit and the internal high temperature, and cannot timely control the fire caused by the short circuit

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Eccentricity | aaaaa | aaaaa |

Login to View More

Abstract

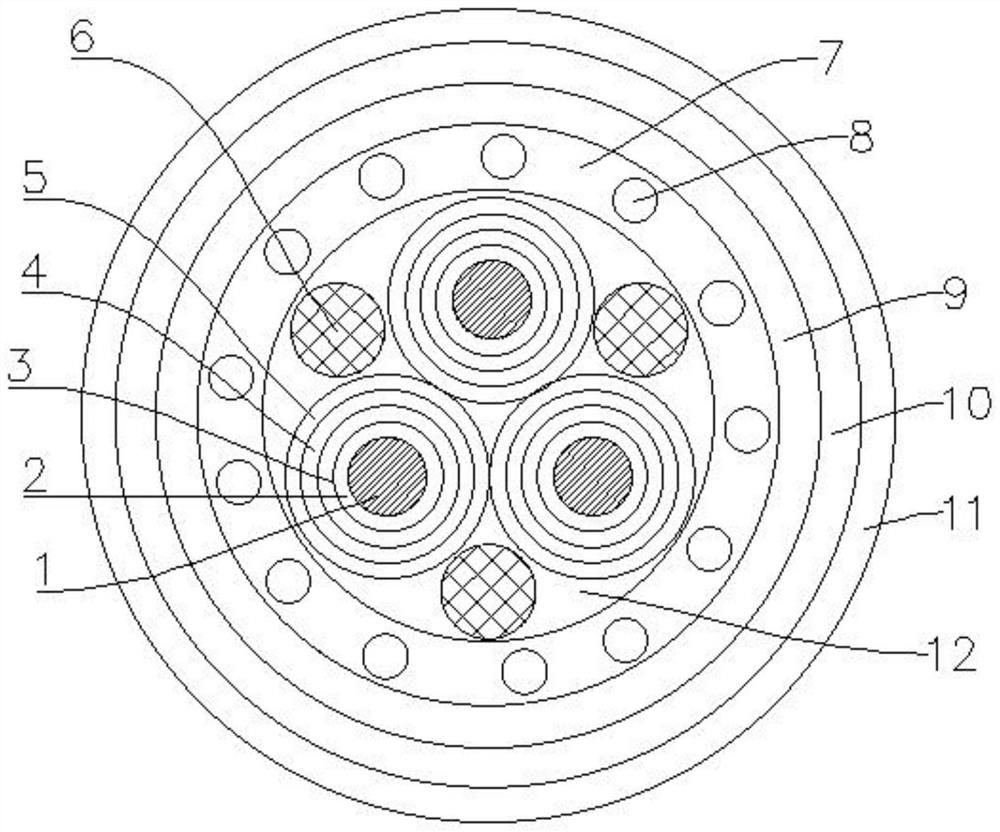

The invention relates to a medium-voltage fire-resistant power cable, which includes a cable core, a cooling layer, a fire-resistant composite layer, a metal armor layer and a sheath. The cooling layer is covered with several cable cores, and the cooling layer is from the inside to the outside. The refractory composite layer, the metal armor layer and the sheath are covered in sequence. The cable core includes a plurality of wire core bundles, and several dry powder tubes are arranged in the gaps between the multiple wire core bundles, and the dry powder tubes are filled with Fire extinguishing agent, the wire core bundle includes a conductor and a conductor shielding layer, an insulating layer, an insulating shielding layer and a metal shielding layer coated outside the conductor, and the conductor shielding layer, the insulating layer and the insulating shielding layer adopt a three-layer co-extrusion method One-time molding is extruded on the conductor. The medium-voltage fire-resistant power cable of the present invention has a certain fire resistance and cooling performance, and can ensure the transportation of power and signals when a fire occurs, or has the effect of fire extinguishing and flame retardancy when a short-circuit fire occurs.

Description

A medium-voltage fire-resistant power cable technical field [0001] The present invention relates to the technical field of cables, in particular to a medium-voltage fire-resistant power cable. Background technique With the sustained and high-speed development of my country's economy, important public buildings such as modern office buildings, hotels, restaurants, railway stations, etc. The decoration of public places is becoming more and more luxurious, and more and more combustibles are used; major and medium-sized cities in the country have successively built subway lines, such as this one. Some important public places require that in the event of a fire, the wires can continuously transmit power and various Control signals and alarm signals are provided for human escape, automatic alarm, activation of fire-fighting facilities, rescue and use of emergency equipment. Precious time, and fire-resistant wire is to ensure that the line is normally energized for a certai...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01B9/02H01B7/42H01B7/295H01B7/29A62C3/16

CPCH01B9/027H01B9/024H01B7/423H01B7/295H01B7/292A62C3/16Y02A30/14

Inventor 代荣记张拓朱冬荣蔡志祥欧阳从军班龙城

Owner 上海业燊科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com