Flame-retardant manufacturing method of external wall thermal insulation non-woven fabric

A technology of external wall insulation and production method, which is applied in the direction of textiles, papermaking, fiber processing, etc., can solve the problems of high production cost of thermal insulation materials, influence of thermal insulation effect, and easy deterioration, etc., and achieve permanent and effective flame-retardant and heat-insulating effects. The cost economy, the effect of avoiding fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

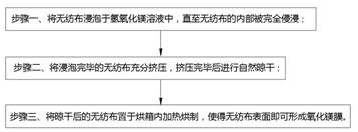

[0016] see figure 1 , the present invention provides a kind of technical scheme:

[0017] A method for producing flame-retardant non-woven fabrics for thermal insulation of external walls.

[0018] Step 1, soak the non-woven fabric in the magnesium hydroxide solution, and its concentration is 5%, until the inside of the non-woven fabric is completely soaked;

[0019] Step 2, fully extruding the soaked non-woven fabric, and drying it naturally after extruding;

[0020] Step 3: Place the air-dried non-woven fabric in an oven for heating and drying, and the heating temperature is 340°C, so that the surface of the non-woven fabric can form a magnesium oxide film that can withstand a temperature of up to 2852°C.

specific Embodiment 2

[0021] see figure 1 , the present invention provides a kind of technical scheme:

[0022] A method for producing flame-retardant non-woven fabrics for thermal insulation of external walls.

[0023] Step 1, soak the non-woven fabric in the magnesium hydroxide solution, and its concentration is 30%, until the inside of the non-woven fabric is completely soaked;

[0024] Step 2, fully extruding the soaked non-woven fabric, and drying it naturally after extruding;

[0025] Step 3: Place the air-dried non-woven fabric in an oven for heating and drying, and the heating temperature is 400°C, so that the surface of the non-woven fabric can form a magnesium oxide film that can withstand a temperature of up to 2852°C.

specific Embodiment 3

[0026] see figure 1 , the present invention provides a kind of technical scheme:

[0027] A method for producing flame-retardant non-woven fabrics for thermal insulation of external walls.

[0028] Step 1, soak the non-woven fabric in the magnesium hydroxide solution, and its concentration is 40%, until the inside of the non-woven fabric is completely soaked;

[0029] Step 2, fully extruding the soaked non-woven fabric, and drying it naturally after extruding;

[0030] Step 3: Place the air-dried non-woven fabric in an oven for heating and drying, and the heating temperature is 450°C, so that the surface of the non-woven fabric can form a magnesium oxide film that can withstand a temperature of up to 2852°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com