Sealing and blocking integrated efficient water blocking tubular column and oil extraction method

A high-efficiency technology for plugging pipes, applied in earthwork drilling, sealing/isolation, wellbore/well components, etc., to achieve the effect of small unsealing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

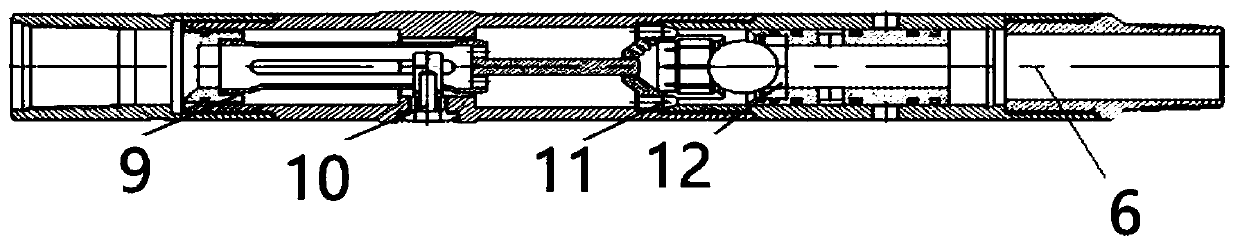

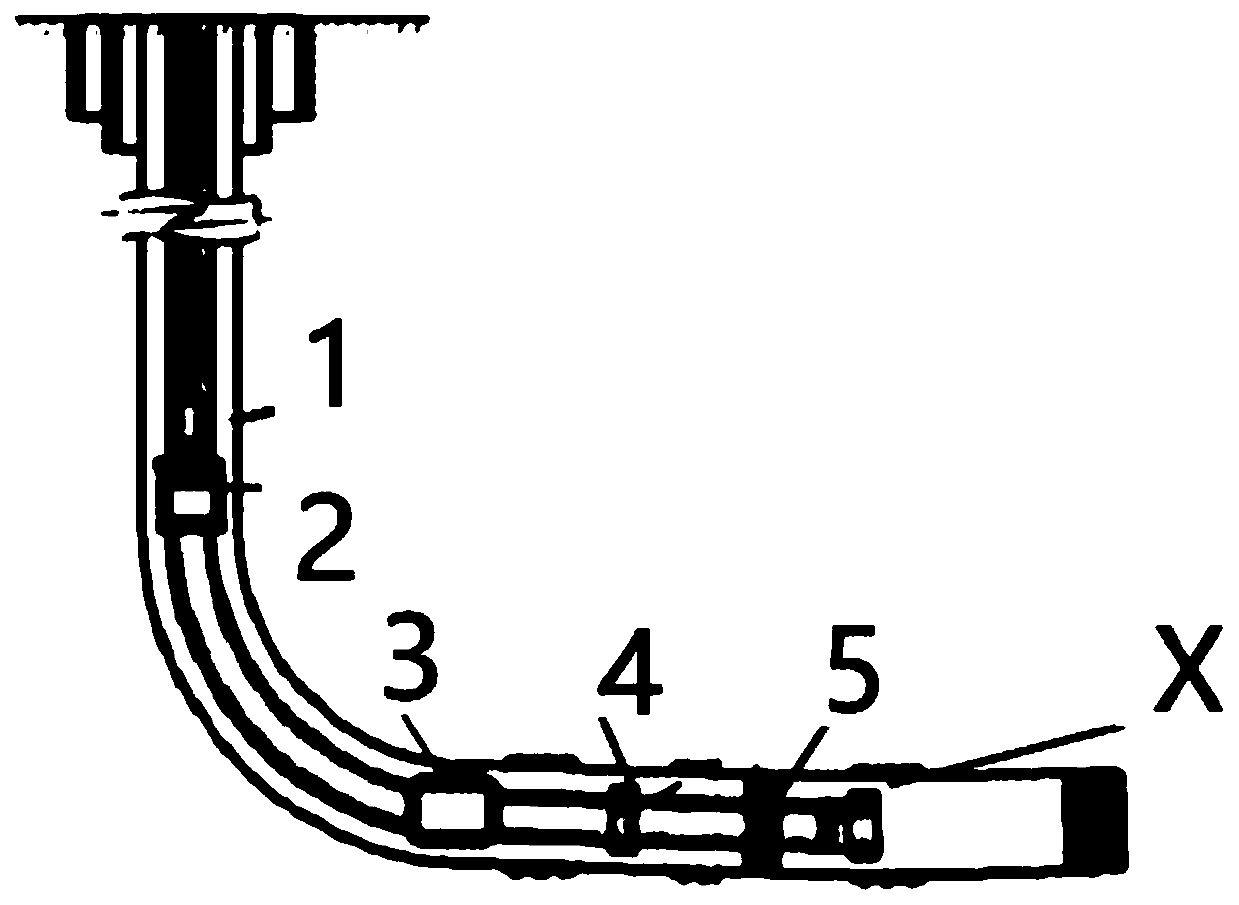

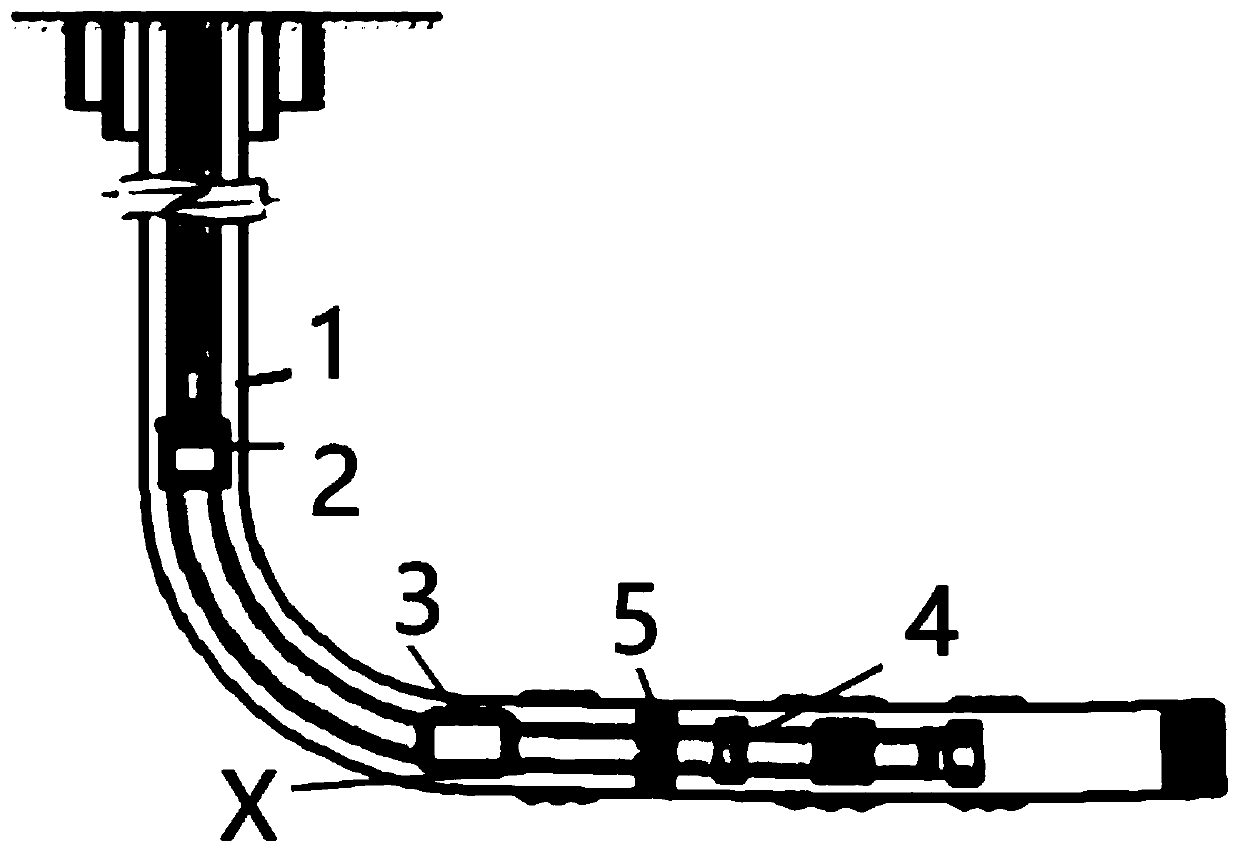

[0030] 1. The composition and principle of the pipe string The integrated high-efficiency water shut-off pipe string composed of oil well pump, multi-functional valve group, telescopic compensator, Y241 horizontal well special water shut-off packer, setting sliding sleeve, etc. It can be unsealed by lifting the string, and the unsealed load is small, safe and reliable. Mainly, the one-way slip packer is used to seal the water-producing section outside the tubing, and the fluid in the oil-producing section enters the tubing through the tubing tee of the setting sliding sleeve, and is extracted from the ground through the oil well pump, realizing the integration and high efficiency of horizontal wells blockage. Two sets of packers, Y241 and Y341, are used to seal the middle part. Using the difference in setting pressure, the two sets of packers start to set the Y241 packer, and when the pressure increases, the Y341 packer seals the middle part.

[0031] Technical string type

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com