Paper box drying equipment for compacting side interior

A technology for drying equipment and cartons, which is applied in the field of carton drying equipment compacted on the opposite side, which can solve the problems of affecting the use of cartons, reducing the stress area, and low strength of cartons, so as to achieve reasonable design, The effect of plump shape and strong function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

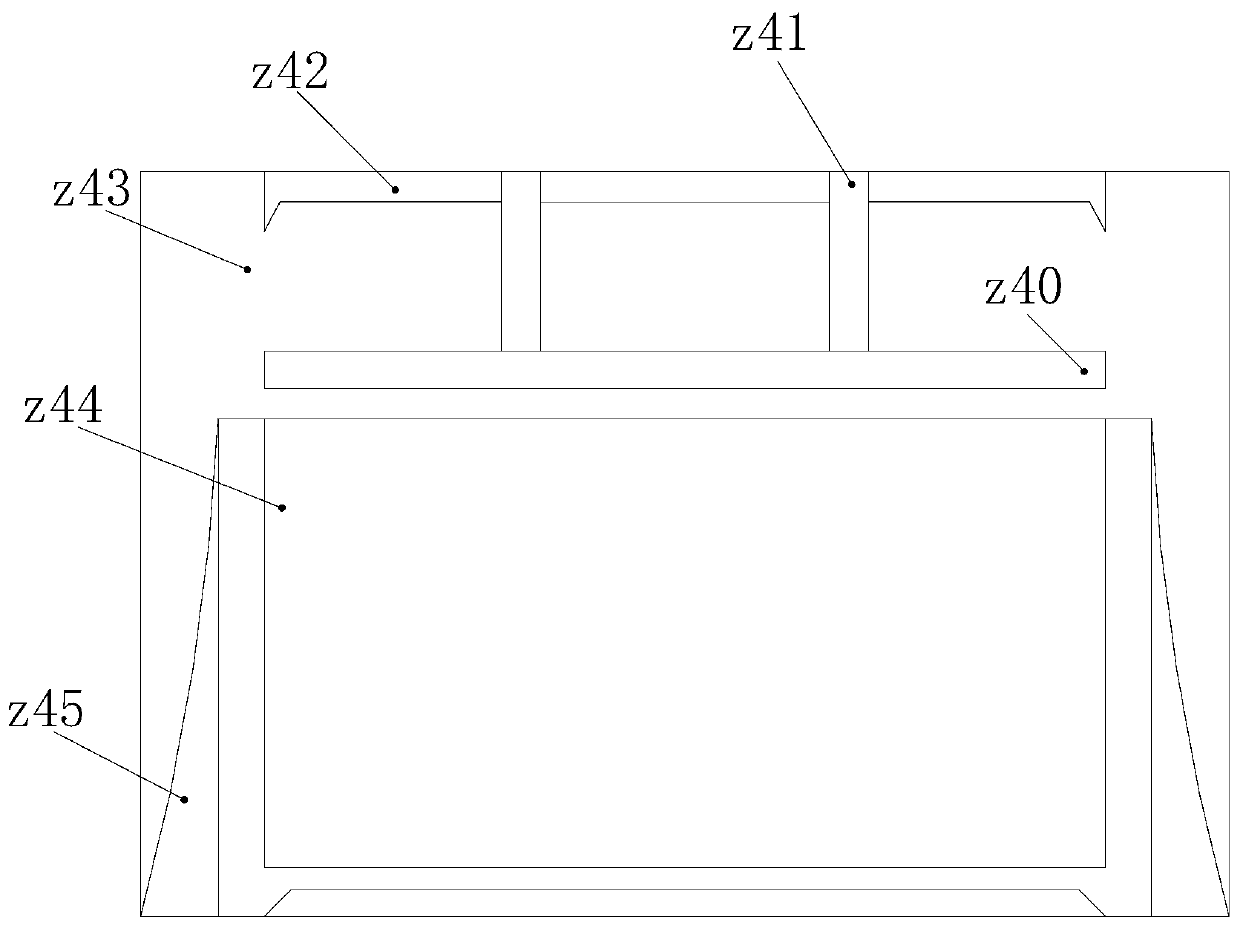

[0028] as attached figure 1 to attach Figure 5 As shown, the present invention provides a carton drying equipment compacted on the opposite side, its structure includes a sealing door z1, a conversion heat cylinder z2, a shifting frame z3, a drying heat box z4, and a distance adjustment head z5. The sealing door z1 is hinged on the right side of the drying heat box z4, the conversion heat cylinder z2 is provided with four and vertically welded on the top of the drying heat box z4, and the shift frame z3 is locked on the conversion heat tank by rivets. The two sides of the heat cylinder z2 are slidingly connected with the top of the drying heat box z4. The distance adjustment head z5 is mechanically connected to the left side of the shifting frame z3. The drying heat box z4 is composed of an attached guide plate z40, Vertical guide column z41, encapsulation bag z42, sealing box z43, heat drying box z44, heat wrapping pad z45, the encapsulation bag z42 passes through the top i...

Embodiment 2

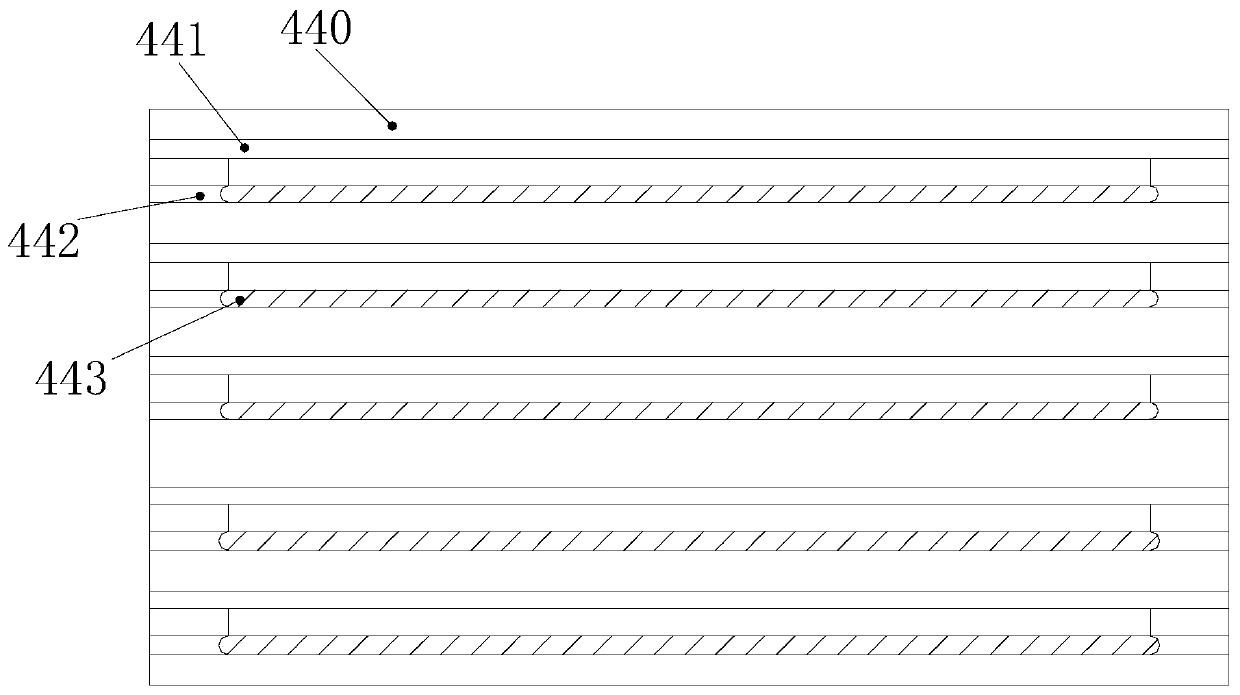

[0032] On the basis of embodiment 1, as attached Figure 6 As shown in appendix 7, the present invention provides a carton drying equipment compacted on the opposite side. The heat wrapping pad z45 is composed of a buckle chuck 450, a parallel arm 451, and a joint longitudinal bar 452. The joint longitudinal bar 452 is welded together with the bottom of the inside of the sealed box z43. The parallel arm 451 is provided with two vertical nails connected to the left and right ends of the longitudinal bar 452. The buckle chuck 450 is hinged inside the parallel arm 451, each A buckle chuck 450 corresponds to the side of each cardboard to improve the edge closing effect of the cardboard edge. The buckle chuck 450 is composed of an inner pressure plate 500, a shrinking sheet 600, a shrinking ball 700, and a clamping frame 800. The inner shrinking The ball 700 is hinged inside the side-by-side arm 451, the shrinking piece 600 is mechanically connected to the upper and lower ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com