Gradually-pressed direct pressure water pumping tube well

A water pipe, direct pressure technology, applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of long time consumption, high pumping costs, increased labor and materials, etc., to achieve short construction period, less labor, and savings cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

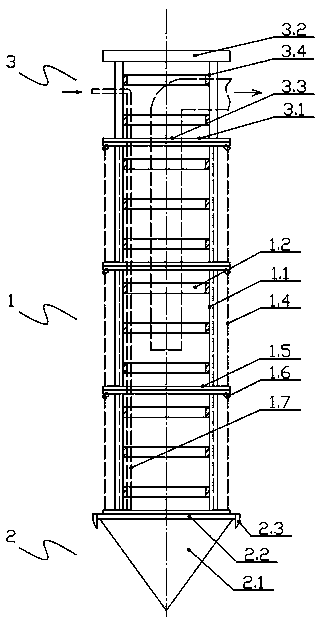

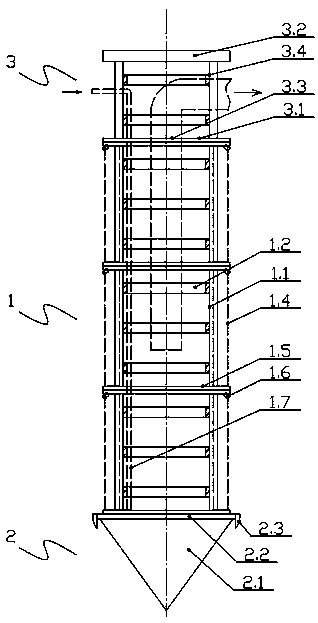

[0022] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

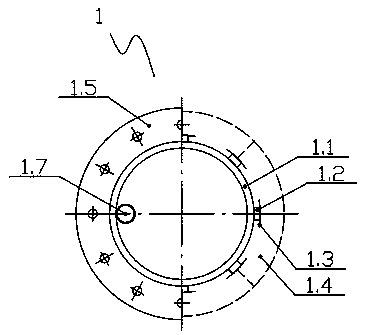

[0023] Such as Figure 1 to Figure 2 As shown, the step-by-step direct pressure water intake pipe well of the present invention includes a lattice type inlaid filter box water storage pipe joint 1, a bottom cone press-in pipe joint 2 and a top pressurized pipe joint 3, and the bottom cone press-in pipe joint 2 is articulated At the lower end of the grid-type filter box water storage pipe joint 1, in this embodiment, the lattice-type filter box water storage pipe joint 1 has three sections, and the top pressurized pipe joint 3 is connected to the uppermost section. The upper end of the filter box water storage pipe joint 1 is inlaid with the structure.

[0024] The lattice-type filter box water storage pipe joint 1 includes a lattice-type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com