Foundation pit prefabricated fender shock absorption pile and foundation pit retaining wall building method

A foundation pit enclosure and foundation pit technology, applied in sheet pile walls, excavation, construction, etc., can solve the problems of small environmental impact, low labor intensity, high labor intensity, etc., and achieve the effect of less construction waste and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

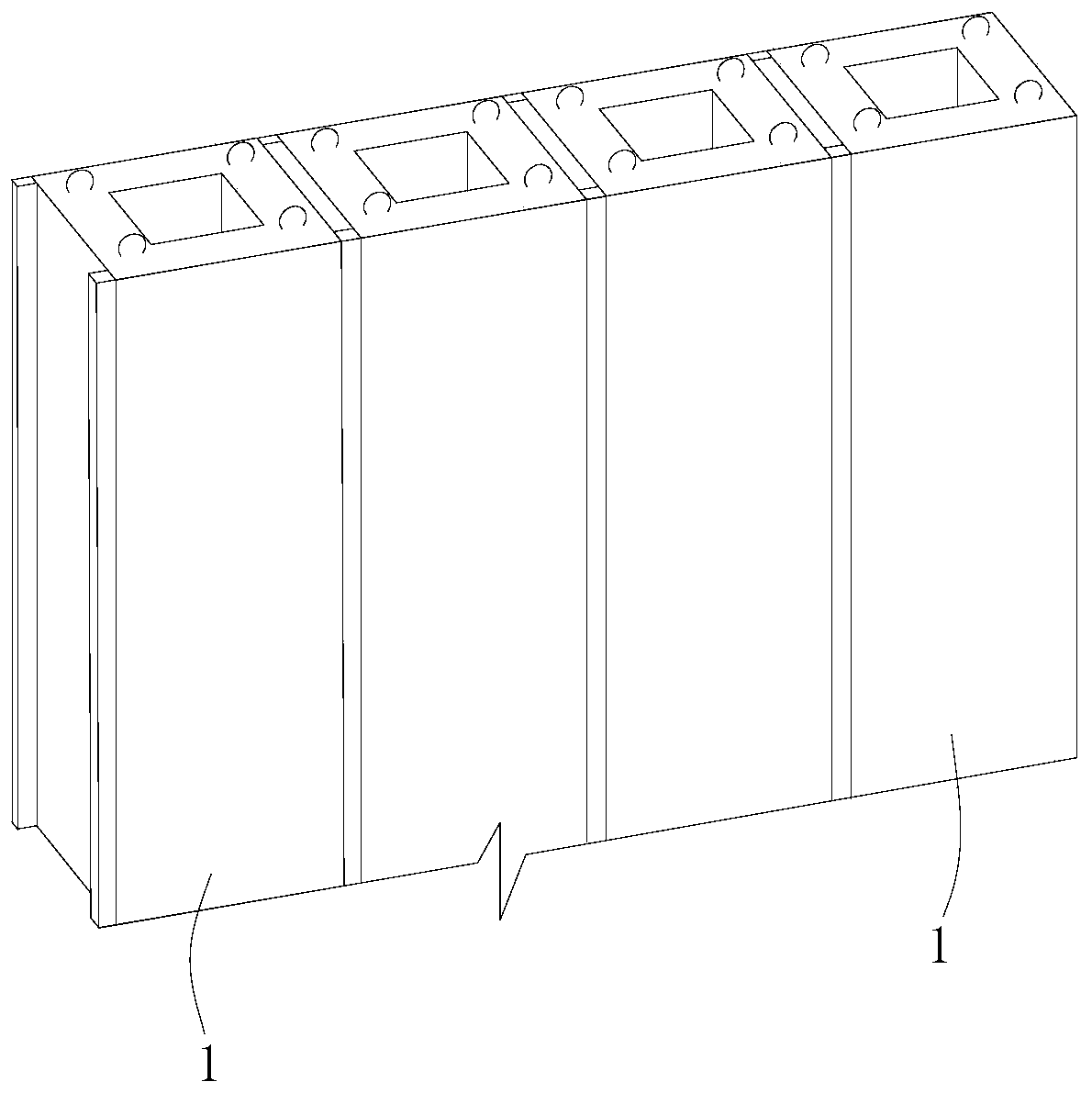

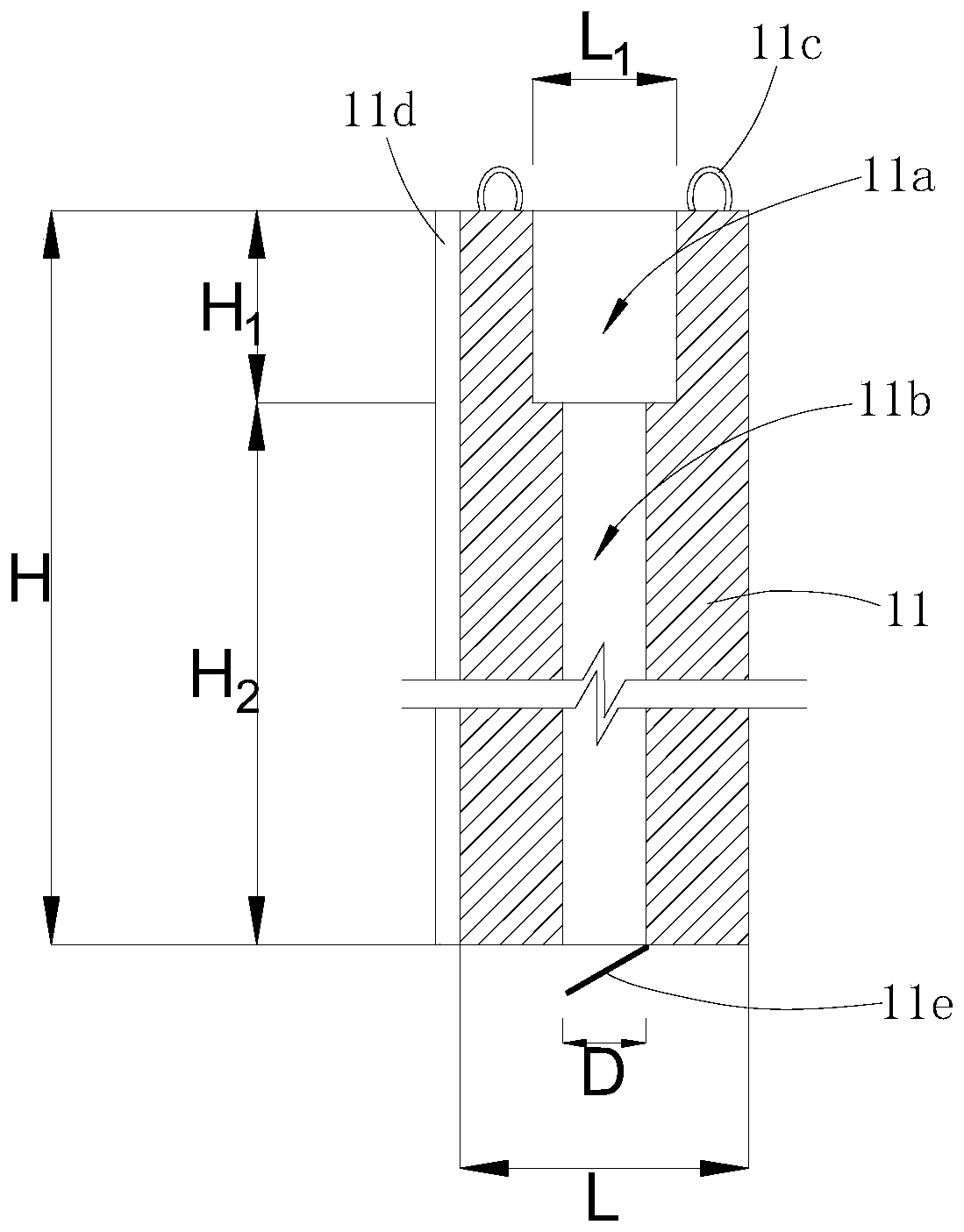

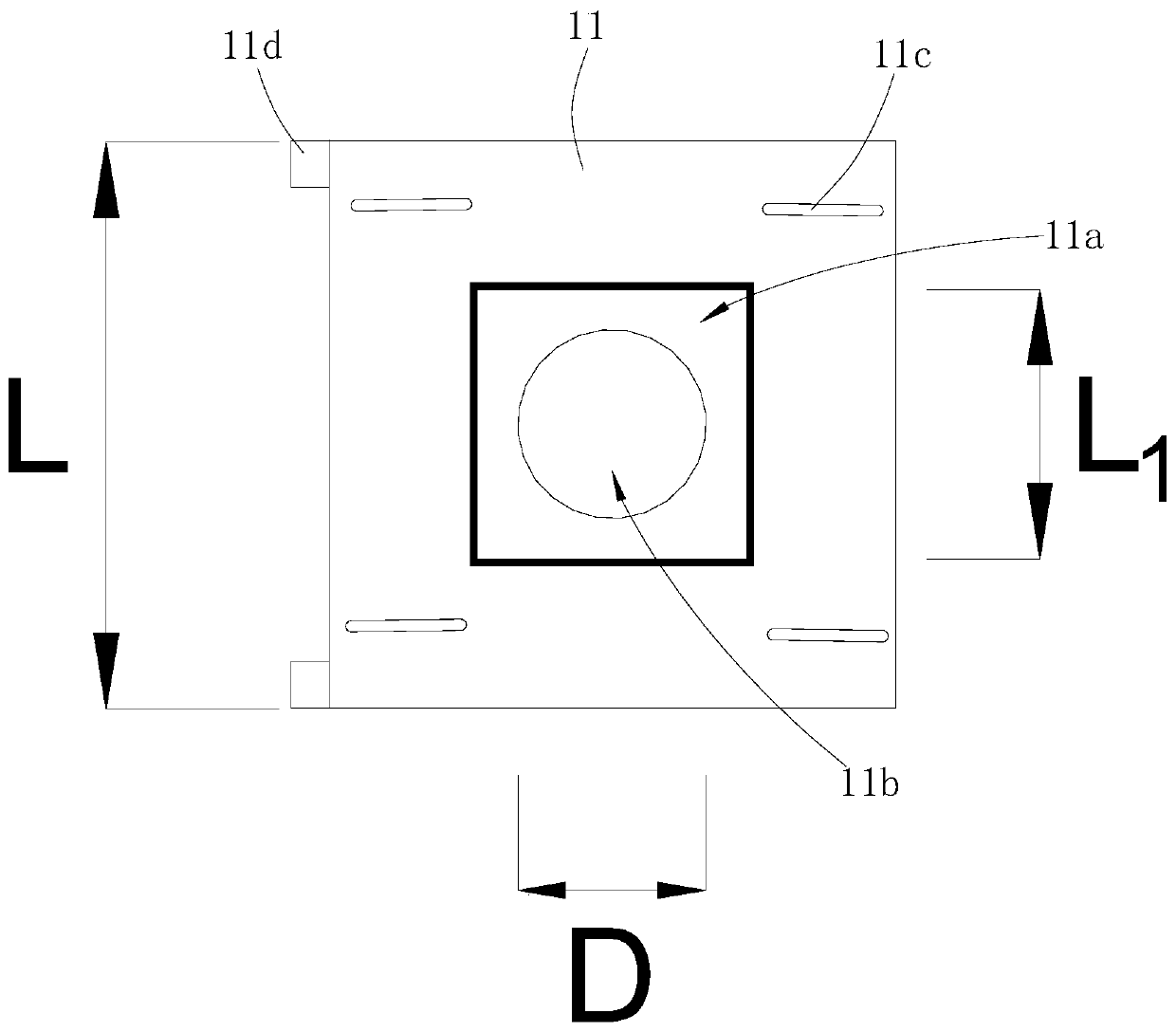

[0036] like Figures 1 to 4 shown

[0037] The foundation pit prefabricated enclosure damping pile 1 includes a pile body 11 and a cover plate 12 .

[0038] The pile body 11 is a reinforced concrete square pile with a cross-sectional size of 598mm×598mm and a height of 8000mm. There is a square liquid storage tank 11a on the upper end of the pile body 11. The cross-sectional size of the liquid storage tank 11a is 300mm×300mm and the depth is 400mm. , the pool wall of the liquid storage tank 11a is paved with a waterproof coiled material, and the waterproof coiled material is an elastomer-modified asphalt waterproof coiled material (SBS waterproof coiled material).

[0039] The bottom of the liquid storage pool 11a is provided with a round hole 11b vertically penetrating the lower end of the pile body 11, with an inner diameter of 200mm and a length of 7600mm. road.

[0040] Four hooks 11c for lifting are preset on the top of the pile body 11 .

[0041] The bottom of the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com