Bioreactor

A technology of bioreactor and reaction tank, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instrument, etc. and other problems, to achieve the effect of reducing death due to hypoxia, increasing reaction yield, and wide distribution of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

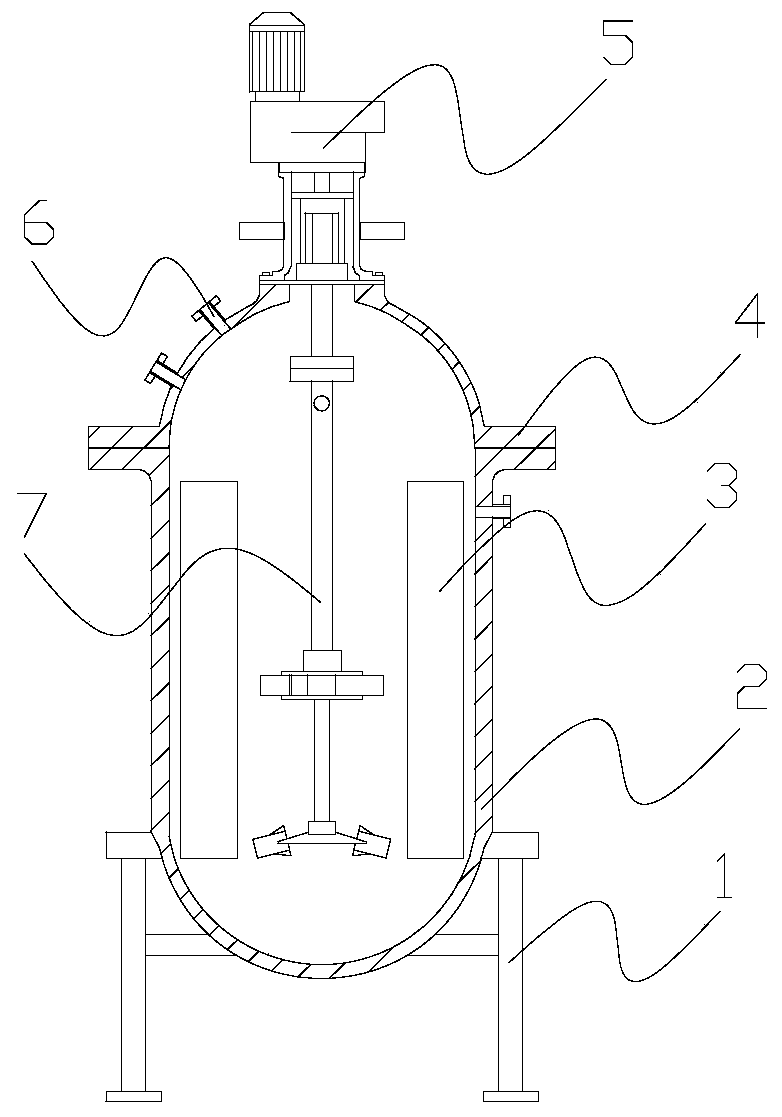

[0032] Example 1: Please refer to Figure 1-Figure 10 , the specific embodiments of the present invention are as follows:

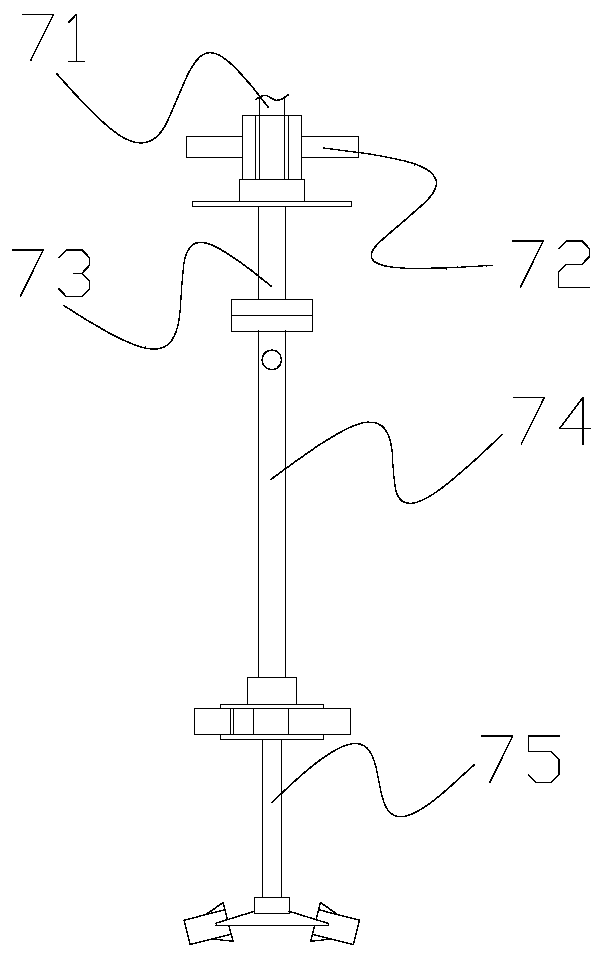

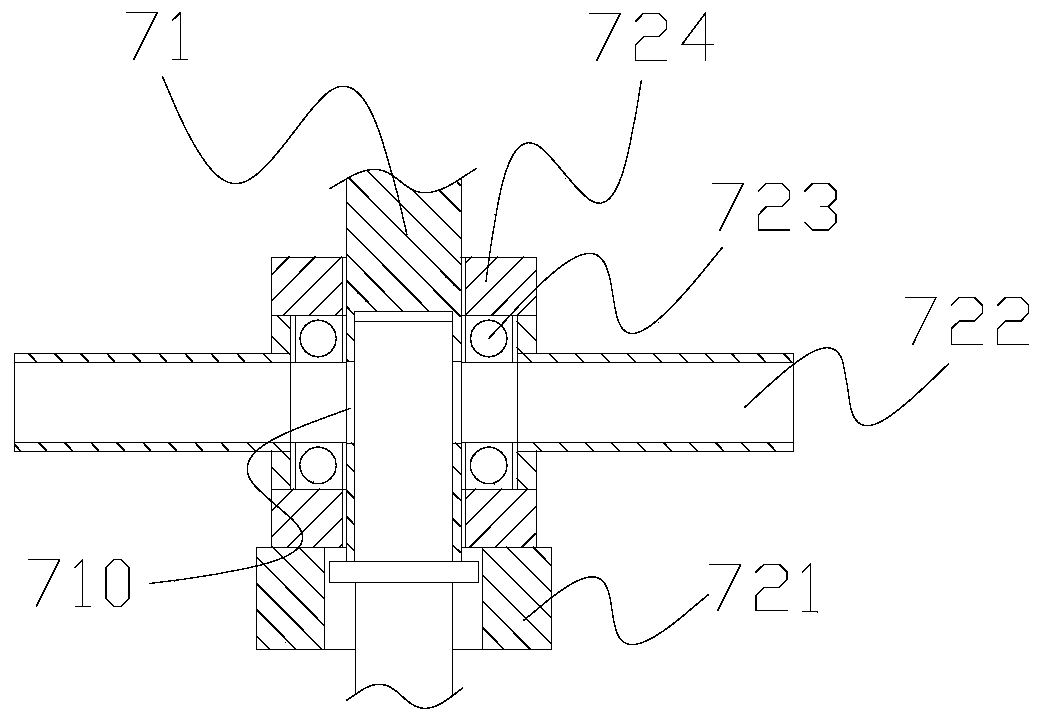

[0033] Its structure includes a chassis 1, a reaction tank 2, a heat exchange plate 3, a tank cover 4, a drive box 5, a feed inlet 6, and an aeration mixing structure 7. The reaction tank 2 is vertically installed on the upper end of the chassis 1 and is relatively Welding, the heat exchange plate 3 is embedded and installed inside the reaction tank 2, the tank cover 4 is installed horizontally on the upper end of the reaction tank 2 and is mechanically connected, and the drive box 5 runs through the upper end of the tank cover 4 and the aeration mixing structure 7 The upper end is connected, and the feed inlet 6 is installed on the outside of the tank cover 4 and communicated with the inside of the reaction tank 2; the aeration mixing structure 7 includes a main shaft 71, an air intake structure 72, a connecting pipe 73, a rotating rod 74, a mixing Stru...

Embodiment 2

[0041] Example 2: Please refer to Figure 9-Figure 12 , the specific embodiments of the present invention are as follows:

[0042] The gas mixing structure 754 includes a connection sleeve 54a, a communication structure 54b, and a gas mixing plate 54c. The connection sleeve 54a is horizontally installed on the upper end of the communication structure 54b and is located on the same axis. The gas mixing plate 54c is installed on the outside of the communication structure 54b And the inside is connected.

[0043] refer to Figure 11 , the communication structure 54b includes a body b1, a port b2, an upper communication port b3, and an inner cavity b4, the port b2 runs through the inside of the body b1, and the upper communication port b3 is located at the upper end of the body b1 and is an integrated structure , the inner chamber b4 is located inside the body b1 and communicates with the port b2 and the upper communication port b3 respectively, the gas can pass into the inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com