Flocculating agent for treating printing and dyeing sewage and sewage treatment method

A technology for printing and dyeing sewage and sewage treatment, which is applied in water/sewage treatment, flocculation/sedimentation water/sewage treatment, adsorbed water/sewage treatment, etc. The effect of shortening standing and stratification time, fast settling effect and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

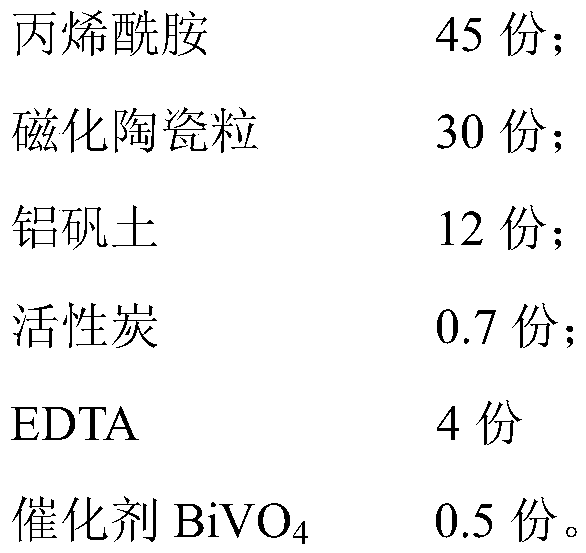

[0030] A flocculant for treating printing and dyeing sewage, specifically comprising the following raw materials in parts by weight,

[0031]

[0032] The magnetized ceramic particles include the following raw materials in parts by weight: ceramic blank Pb 3 o 4 : 70 parts; magnetizable material SrCO 3 : 4.5 parts; magnetizable material MnO 2 : 22.5 copies;

[0033] The preparation method of the magnetized ceramic particles is:

[0034] Step 1, ball milling: firstly mix the magnetizable material and the ceramic blank, and then add deionized water according to the ratio of material to liquid of 1:30; the ball milling time is 4 hours, pass through a 50-mesh sieve, and obtain ceramic slurry A;

[0035] Step 2. Pre-firing: Dry the ceramic slurry A at 120°C, crush it, pass through a 50-mesh sieve, raise the temperature to 1100°C at a rate of 2°C / min, keep it warm for 3 hours, and cool to obtain a pre-fired material;

[0036] Step 3, ball milling again: according to the mate...

Embodiment 2

[0042] A flocculant for treating printing and dyeing sewage, specifically comprising the following raw materials in parts by weight,

[0043]

[0044] The magnetized ceramic particles include the following raw materials in parts by weight: the same as in Example 1.

[0045] The preparation method of the magnetized ceramic particles is as follows: the same as in Example 1.

[0046] A kind of method that utilizes above-mentioned flocculant to carry out sewage treatment: with embodiment 1

Embodiment 3

[0048] A flocculant for treating printing and dyeing sewage, specifically comprising the following raw materials in parts by weight,

[0049]

[0050] The magnetized ceramic particles include the following raw materials in parts by weight: the same as in Example 1.

[0051] The preparation method of the magnetized ceramic particles is as follows: the same as in Example 1.

[0052] A method for sewage treatment using the above-mentioned flocculant: same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com