A tobacco cleaning device

A cleaning device and tobacco leaf technology, applied in cleaning methods and utensils, liquid cleaning methods, chemical instruments and methods, etc., can solve the problems of reducing the income of tobacco farmers, affecting the quality and grade of tobacco, and being unable to clean, etc., to achieve a simple structure , Easy to operate, improve the effect of range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

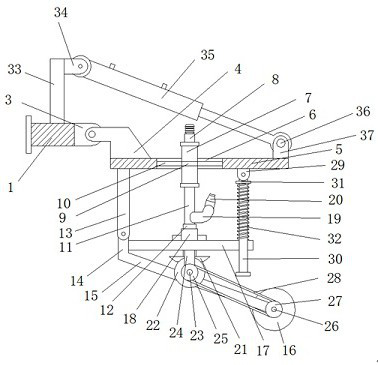

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

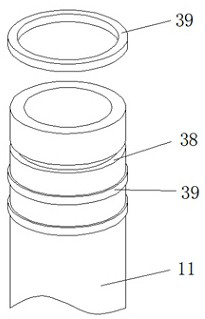

[0019] see Figure 1-2 , the specific embodiment is realized by adopting the following technical scheme, which includes a bar 1 with a long strip structure on the plane, and a hydraulic rod support 2 is vertically installed on the upper top surface of the bar 1, and the bar One side of 1 is welded and fixed with several equidistantly arranged connecting seats 3, and each connecting seat 3 is equipped with a spray mechanism that can be connected and matched with its rotation;

[0020] The spraying mechanism includes a positioning seat 4 that can be rotatably connected with the connecting seat 3. The bottom of the positioning seat 4 is welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com