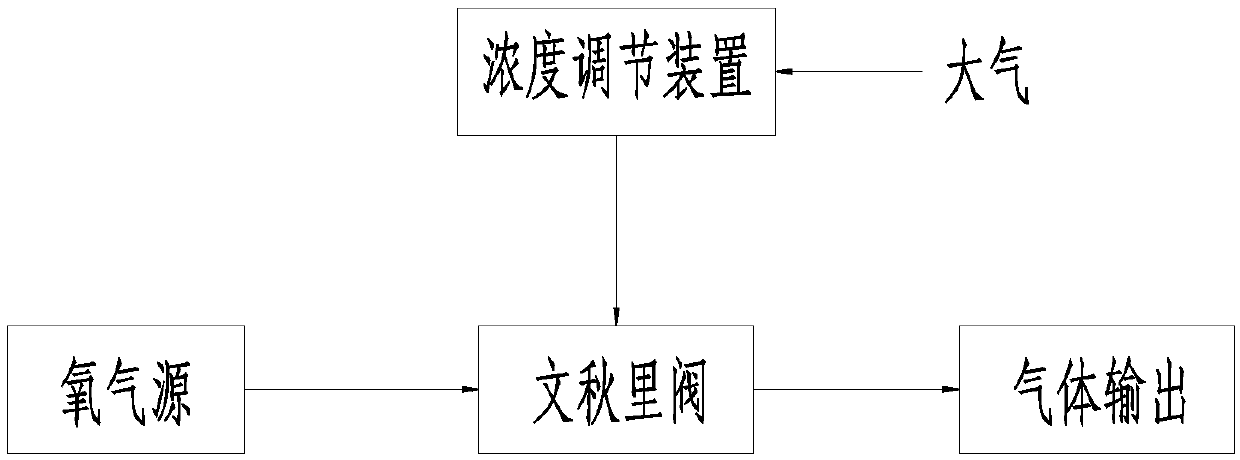

Method for adjusting output oxygen concentration of breathing machine by utilizing venturi valve

An oxygen concentration and venturi technology, applied in respirator, drug equipment, other medical equipment, etc., can solve the problems of not easy operation and complicated adjustment method, and achieve easy operation, simple method and adjustable oxygen concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

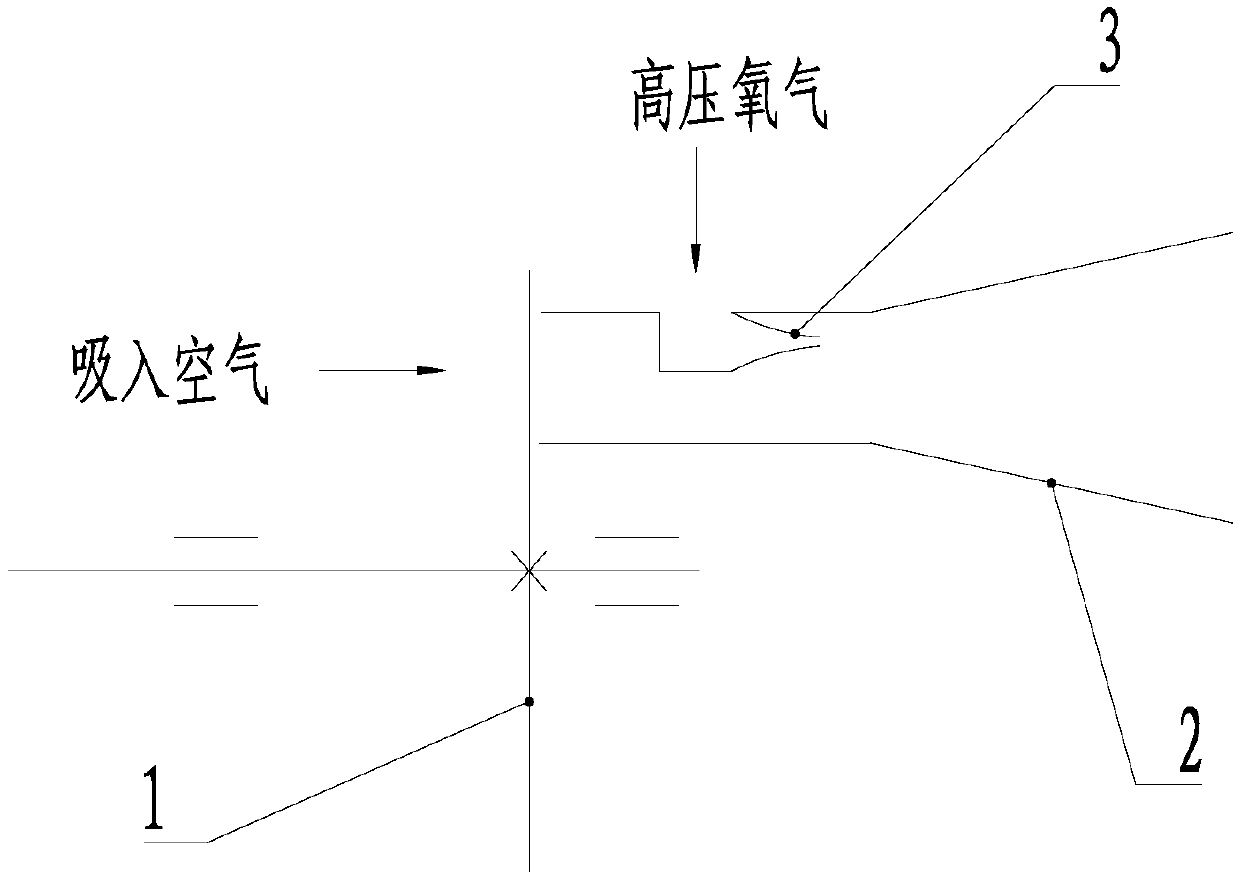

[0013] figure 1 It is the schematic diagram of the gas circuit of the present invention. figure 1 Among them, there is a Venturi valve in the gas path, which includes an air inlet nozzle, an air inlet and an air outlet; high-pressure oxygen is input from the inlet nozzle, and when the high-pressure oxygen is ejected from the nozzle, negative pressure will be generated. The air inlet sucks air in the atmosphere and mixes it with oxygen, and the resulting mixed gas is output from the air outlet. A control device for adjusting the size of the air inlet is provided at the air inlet; through the air inlet control device, the size of the air inlet can be adjusted, thereby adjusting the amount of inhaled air, and then adjusting the oxygen concentration in the mixed gas.

[0014] In order to further illustrate the method of the present invention, an example of applying the method of the present invention will be described below.

[0015] figure 2 It is a structural principle diagr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com