Knuckle bearing reliability analysis method considering fuzzy uncertainty

A joint bearing, uncertainty technology, applied in the direction of electrical digital data processing, instruments, geometric CAD, etc., can solve the problem of low accuracy of results and achieve the effect of comprehensive reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Example embodiments will now be described more fully with reference to the accompanying drawings. Example embodiments may, however, be embodied in many forms and should not be construed as limited to the embodiments set forth herein; rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the concept of example embodiments to those skilled in the art. The same reference numerals in the drawings denote the same or similar structures, and thus their detailed descriptions will be omitted.

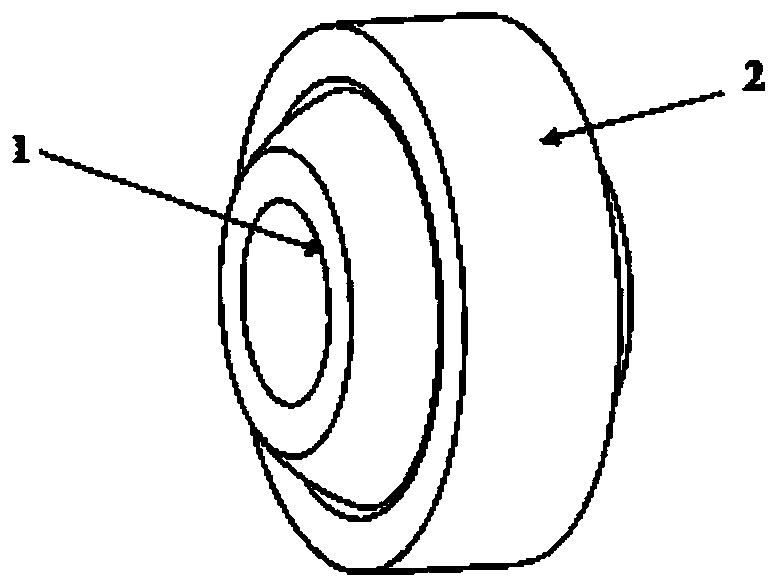

[0052] refer to figure 1As shown, as a general mechanical part, the joint bearing has the characteristics of flexible rotation, compact structure, easy assembly and disassembly, etc., and can meet the requirements of heavy load and long life. It is mainly composed of an inner ring with an outer spherical surface and an outer ring with an inner spherical surface 1, which can bear a large load. According to its different types ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com