Cascade control system and control method for slurry pipeline transportation

A technology of pipeline transportation and cascade control, which is applied in the general control system, control/regulation system, program control in sequence/logic controller, etc., can solve the problem of reducing system operation efficiency and stability, difficulty in coordination of pumping stations, The controlled equipment is far away and other problems, so as to improve the automatic control process, reduce the intensity of manual labor, and reduce the coordination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

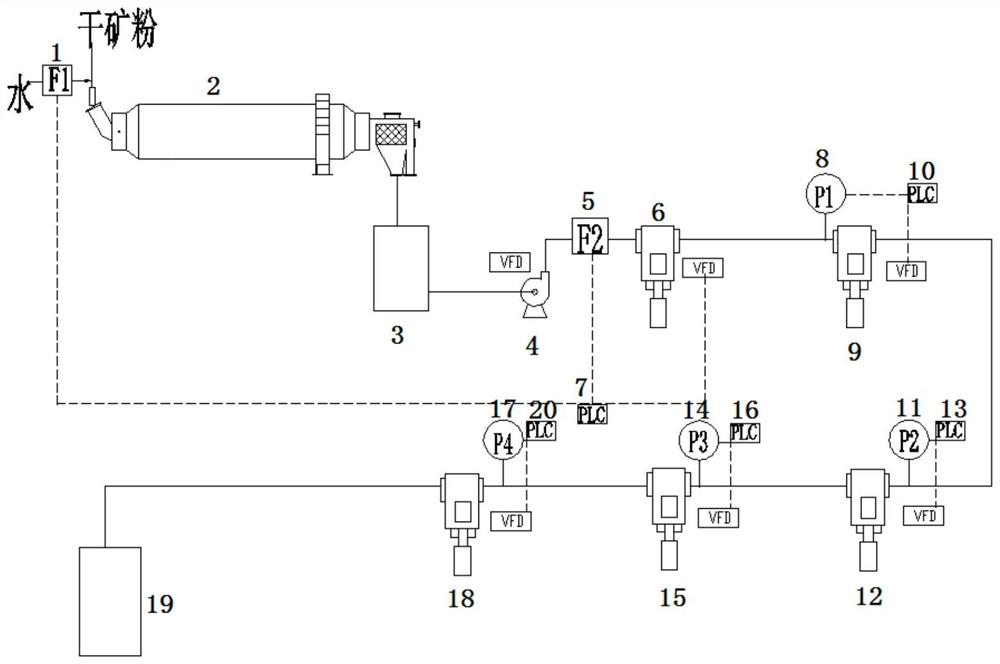

[0043] Such as figure 1 As shown, a slurry pipeline transportation cascade control system of the present invention includes a first-stage pumping station system, a second-stage pumping station system, a third-stage pumping station system, a fourth-stage pumping station system and a fifth-stage pumping station system connected in sequence.

[0044] The first-level pumping station system includes flow transmitter F1 1, mill 2, head-end slurry storage tank 3, slurry feeding pump 4, flow transmitter F25 and first-level pumping station 6 connected in sequence through pipelines;

[0045] Both the flow transmitter F1 1 and the flow transmitter F2 5 are connected to the input end of the first PLC controller 7; the output end of the first PLC controller 7 is connected to the frequency converter of the primary pump station 3 main pump.

[0046] The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com