Multifunctional candle combustion performance automatic tester

A combustion performance and tester technology, which is applied in the direction of using combustion for chemical analysis, etc., can solve the problems of not being able to measure at the same time at the same time, consuming a lot of energy and time, manual intermittent measurement, etc., to save time and energy, convenient maintenance, and high performance. various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

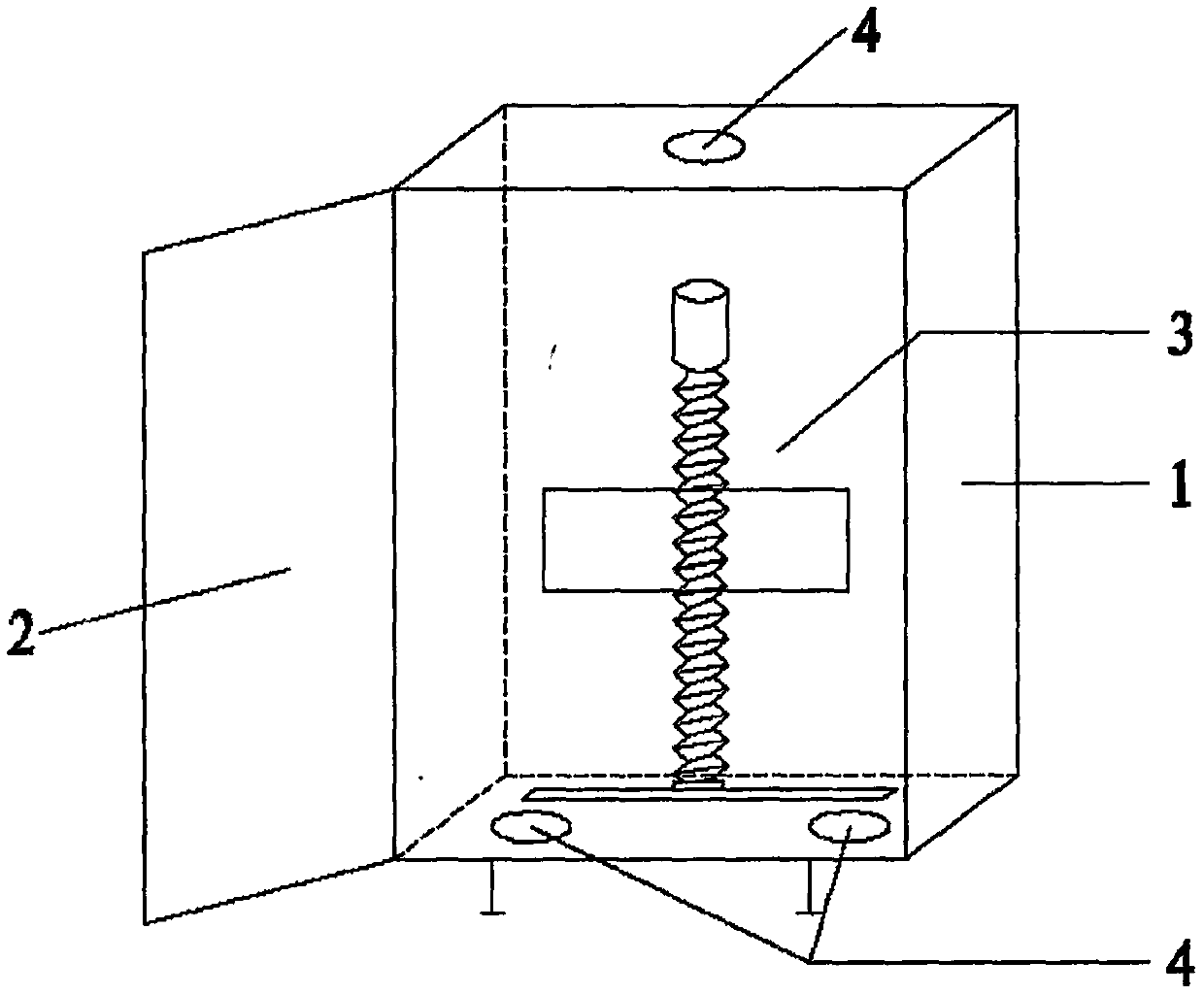

[0022] figure 1 Shown is a multi-functional candle burning performance automatic tester, which is composed of a main box 1 and a light control platform 3 . The light control platform 3 is installed inside the main box body 1. There are two ventilation holes 4 below the main box body 1 and one ventilation hole 4 above. Except for the ventilation holes, the rest of the main box body 1 has no windows or holes to ensure that the interior for the darkroom. The ventilation hole can make the air circulate stably in the main box body 1 and provide oxygen for the burning of the candle.

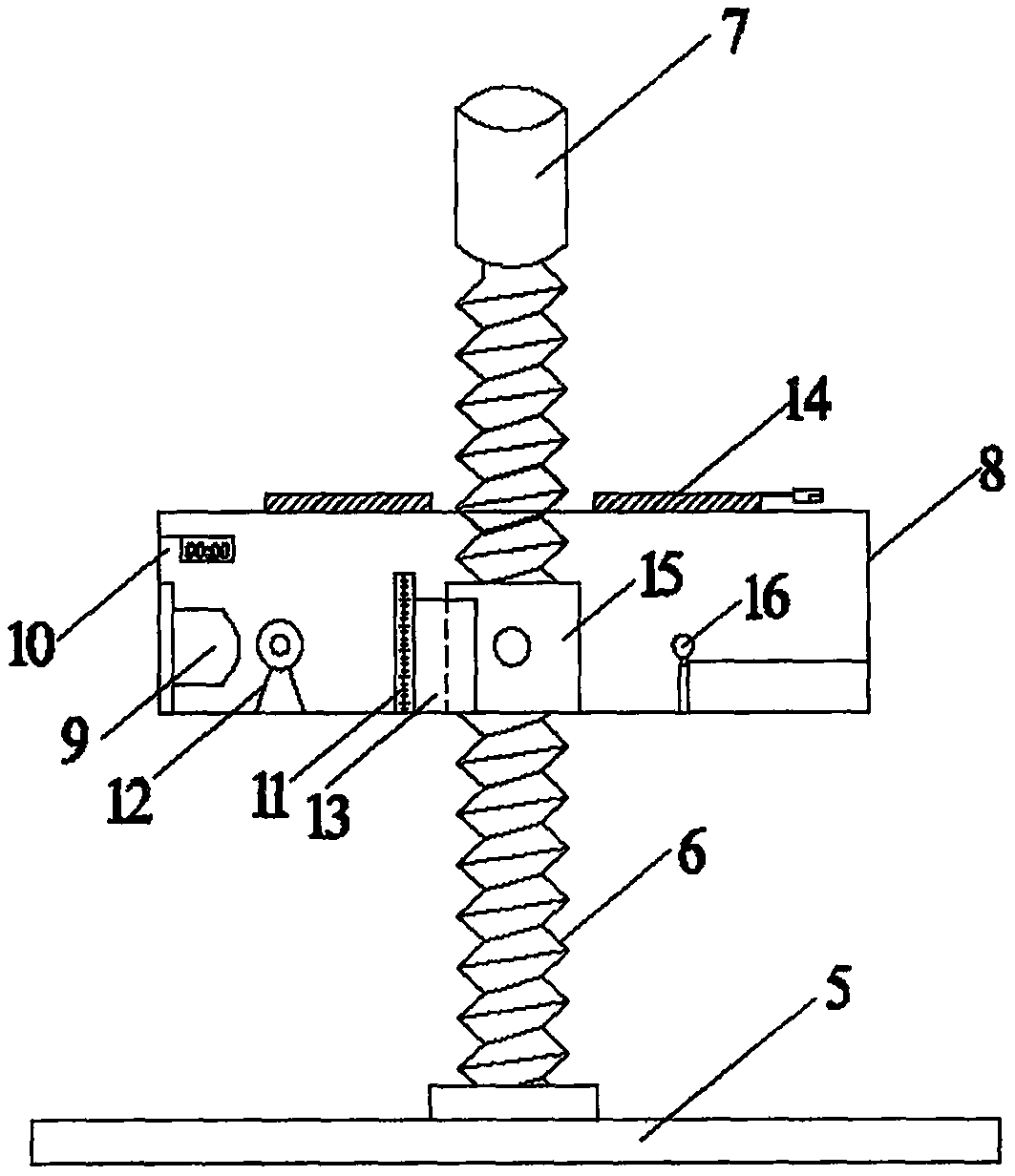

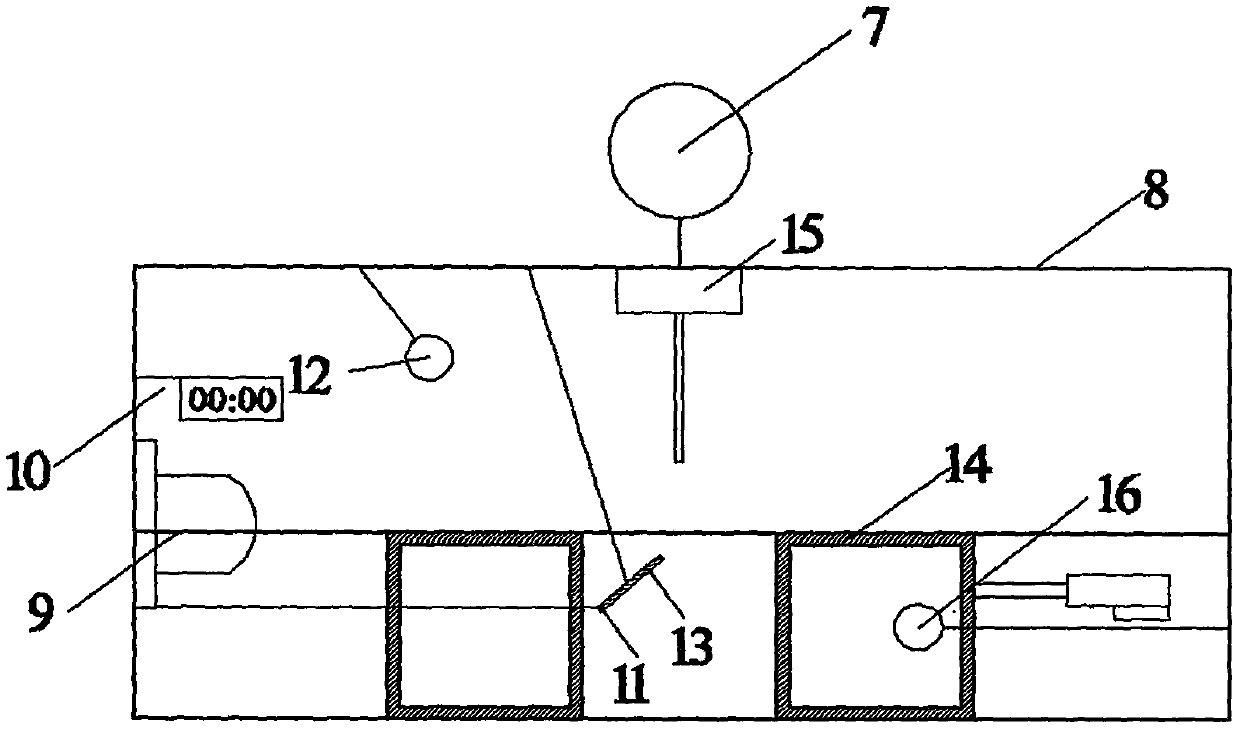

[0023] figure 2 It is a schematic diagram of the main view of the light control platform, image 3 It is a top view schematic diagram of the light control platform. like fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com