A Method for Predicting and Measuring Residual Stress of Cold Rolled Sheet

A technology of residual stress and measurement method, applied in the direction of force/torque/work measuring instrument, measuring force, measuring device, etc., can solve the problems of inconvenient storage of results, radioactive safety problems, long detection time, etc., and achieve high strength after cold forming The effect of steel product quality, low sample requirements, and high sample requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

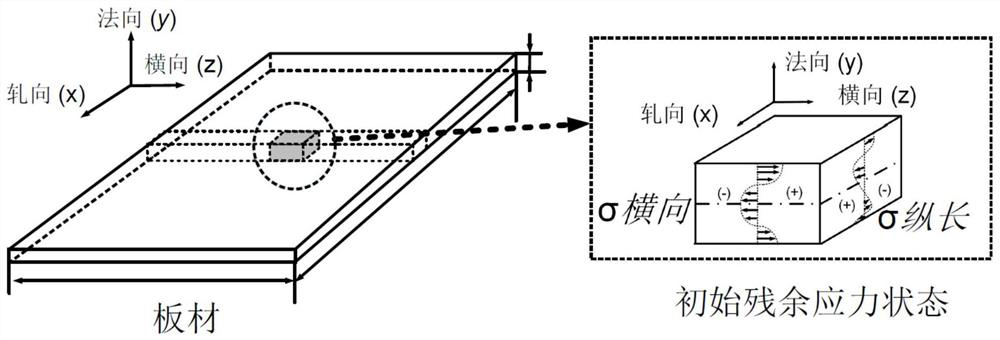

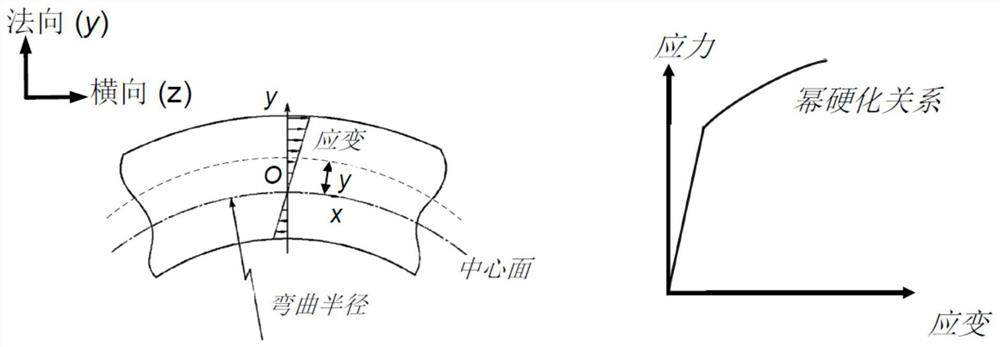

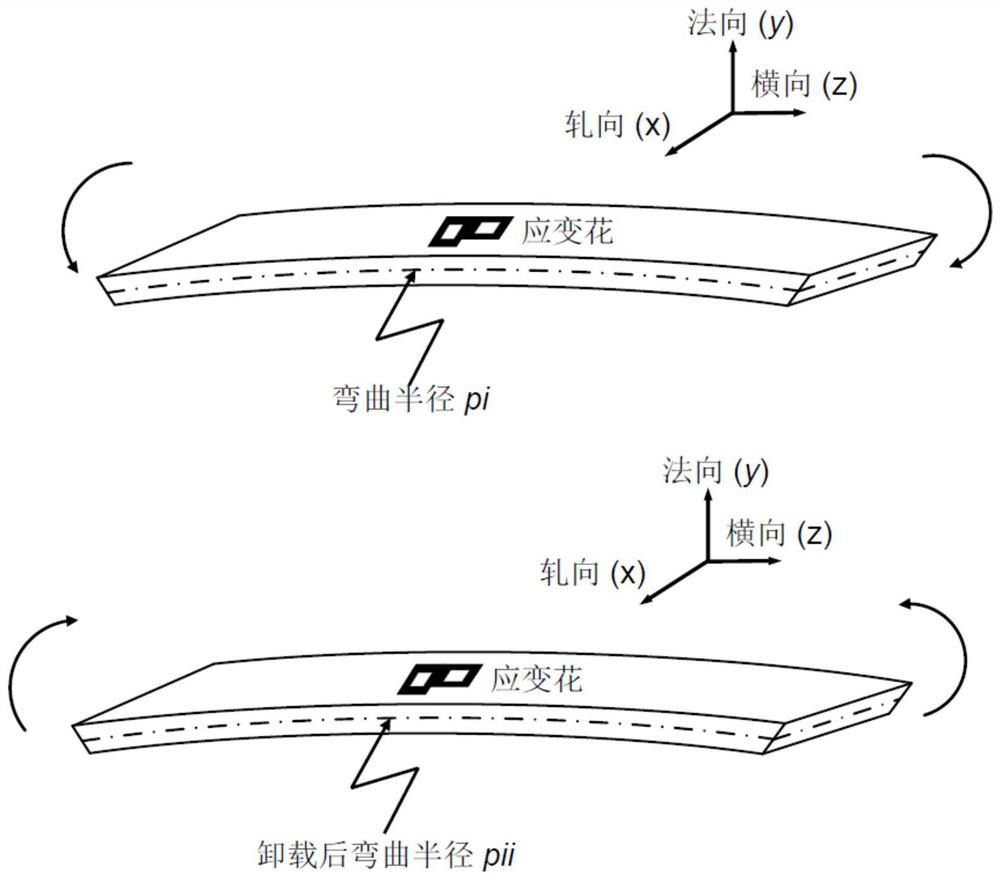

[0043]The internal residual stress is high, especially the rolling direction due to complex rolling reasons and high strength of its own steel sheet. At present, the residual stress detection means of cold rolled sheet is limited, especially along the thickness direction. The residual stress and thickness direction in the cold rolled high-strength steel material is substantially mapped, that is, a thickness corresponds to a certain fixed stress value in a certain crystal plane, and their relationship can be described by a high order polynomial. The method can effectively predict the residual stress distribution along the thickness direction of the sheet by purely bending. Accurate data can be provided for subsequent cold tie plate residual stress control, thereby providing effective control means for improving the quality of high strength steel products after cooling.

[0044] The residual stress prediction and measurement method of the cold rolled plate of the present invention i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com