Assembling equipment and system

A technology for assembling equipment and pressing devices, which is applied in the direction of mechanical equipment, material gluing, connecting components, etc., and can solve the problem of low sensor installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

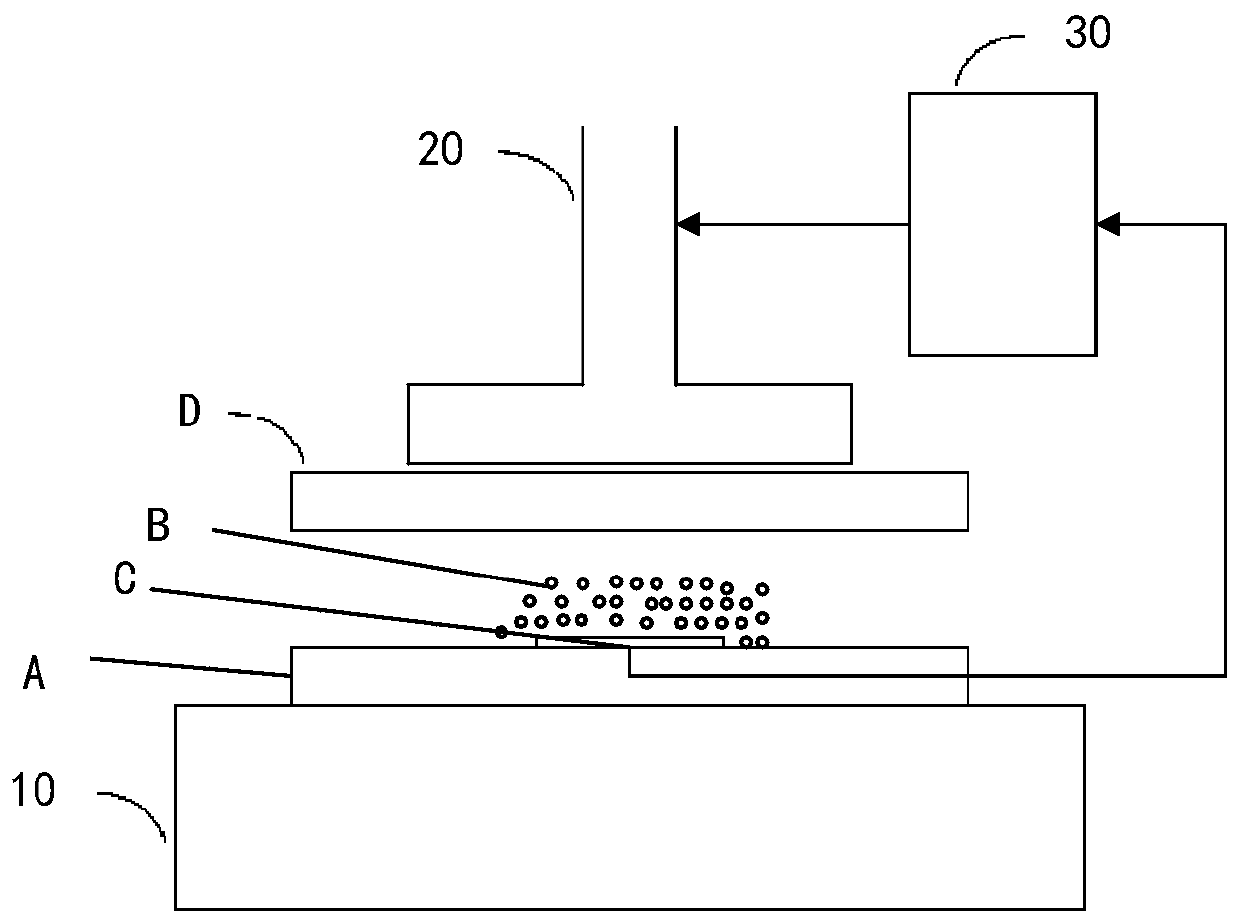

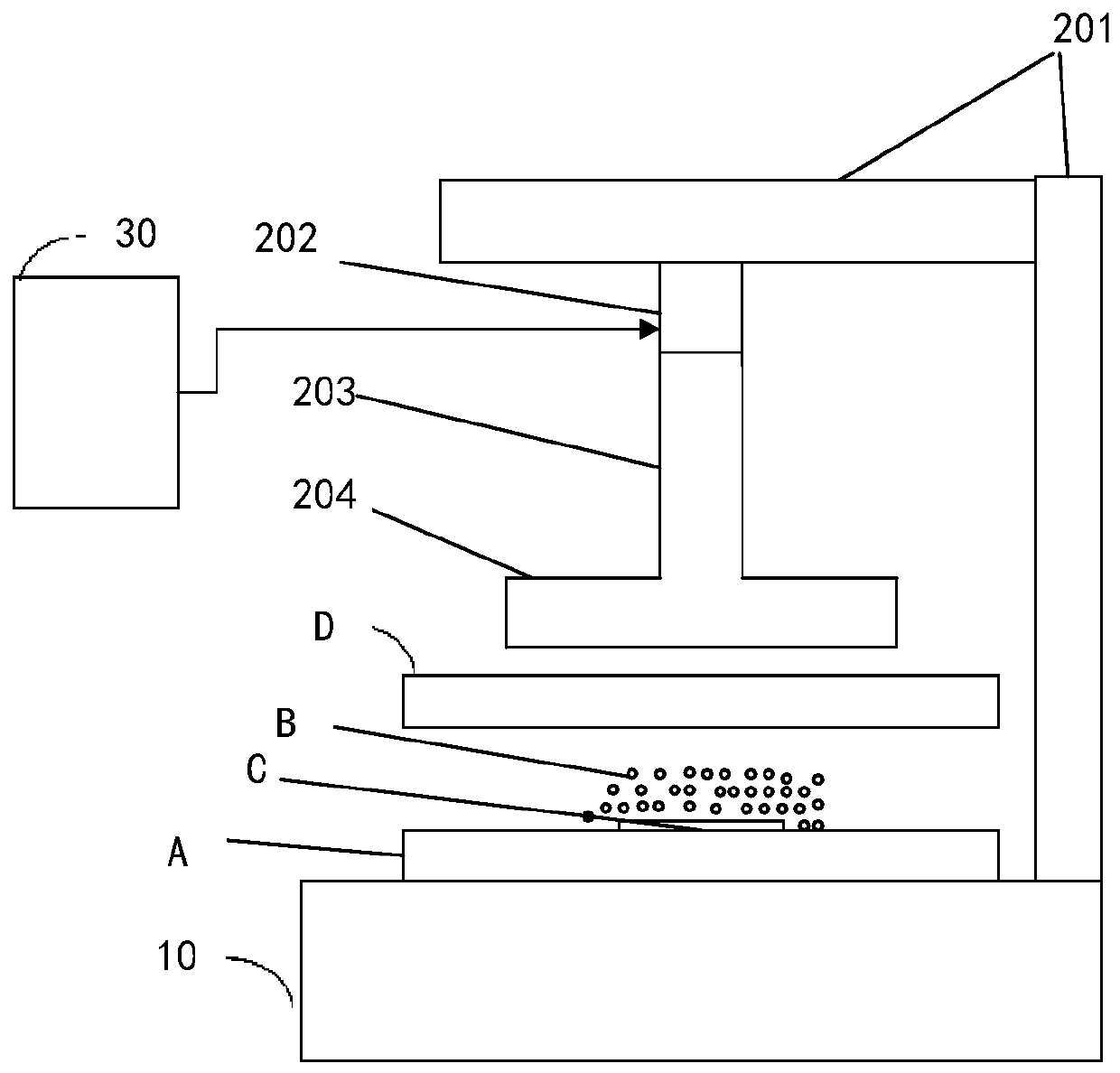

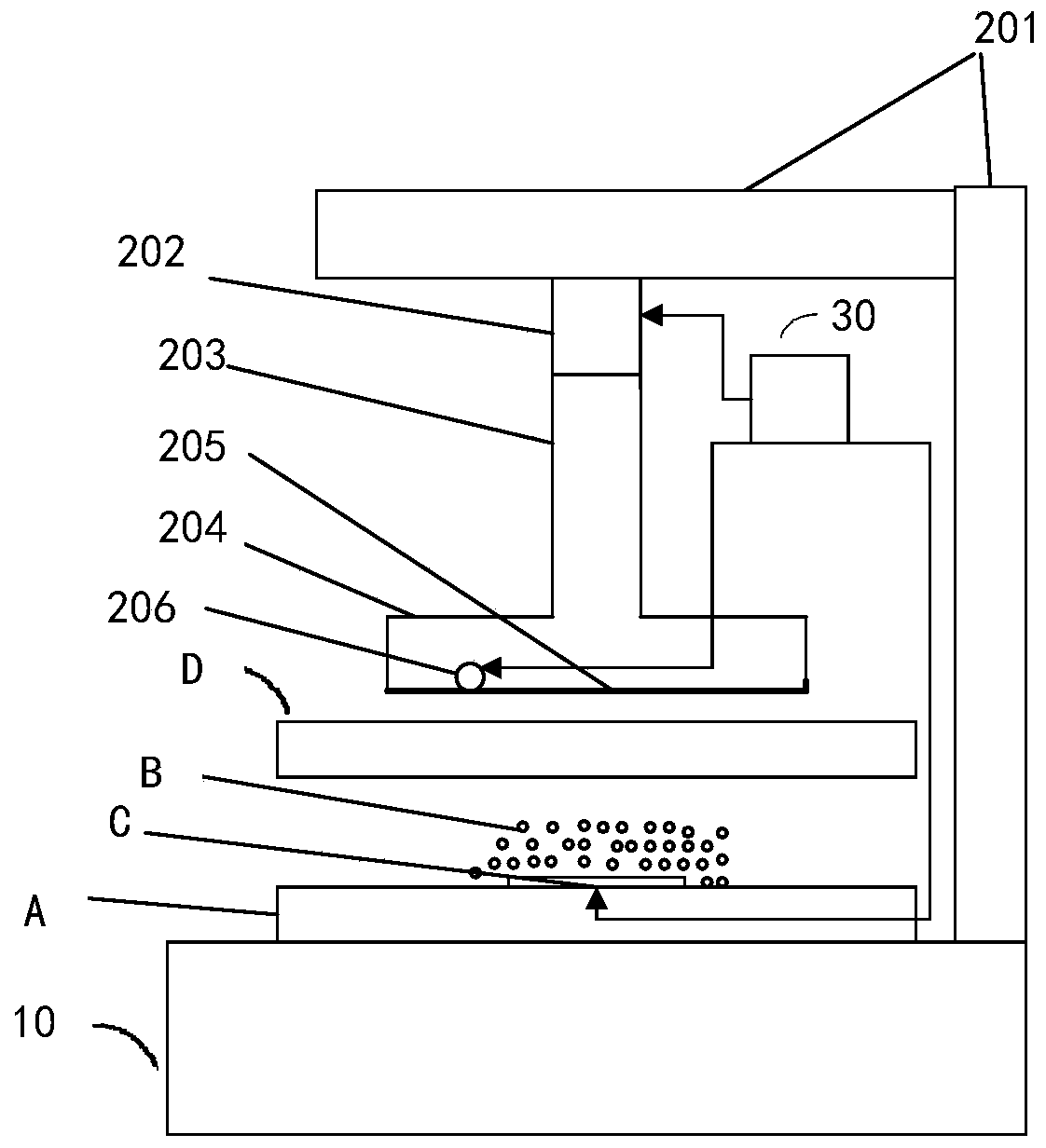

[0024] Such as figure 1 As shown, the embodiment of the present application provides an assembly equipment, the assembly equipment includes a base 10, a heating and pressing mechanism 20 and a controller 30, a device to be pressed is placed on the base 10, and the device to be pressed includes a first Part A, hot melt B, pressure sensor C and second part D, the hot melt B is placed on the first part A, and the hot melt B wraps the pressure sensor C to be assembled. A second part D is placed on the upper part of the pressure sensor C and the hot melt B, and the heating and pressing mechanism 20 is arranged above the second part D, and the heating and pressing mechanism 20 and the pressure sensor C to be assembled are connected with the control device 30 is electrically connected.

[0025] When assembling the assembly equipment designed above, the controller 30 will obtain the initial displacement signal and temperature signal transmitted from the outside, and the force feedbac...

no. 2 example

[0040] The present application provides an assembly system, the system includes an input device and the assembly device described in any optional implementation manner in the first embodiment, the assembly device includes a base, a heating and pressing mechanism and a controller, the input device and The controller is electrically connected, and the input device can be used to receive the operation of the staff to input initial temperature parameters to the controller, etc., and its specific functions and functions are consistent with those described in the first embodiment, and will not be repeated here. .

[0041] In the assembly system designed above, during the assembly process of the pressure sensor, the force parameters of the pressure sensor to be assembled are used as the controller to control the force factor of the heating and pressing device, so that the controller continuously controls the pressure value of the heating and pressing mechanism. Changes, and then make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com