Rotary medicine chamber and inner chamber large-interference-quantity assembly process

An assembly process and interference technology, which is applied in the large interference assembly process field of the rotating drug chamber and the inner bore, can solve the problems of inner bore performance changes, cold and brittle inner bore, and difficulty in cooling the inner bore, and achieve assembly Accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

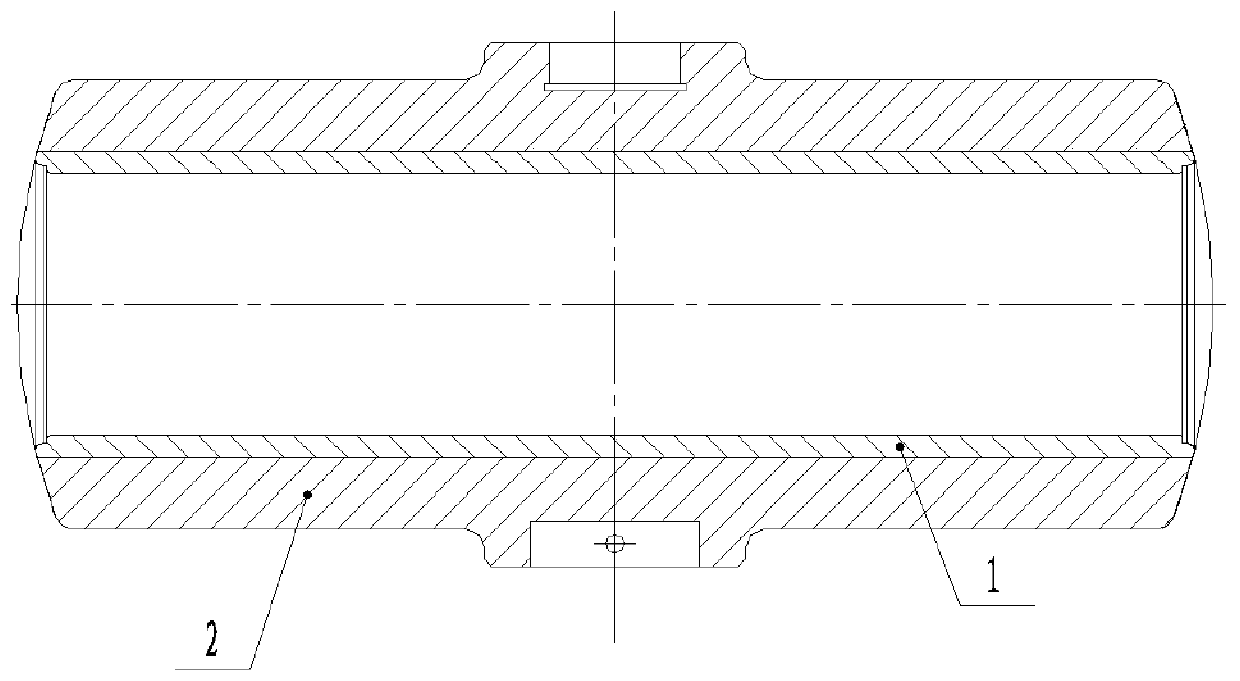

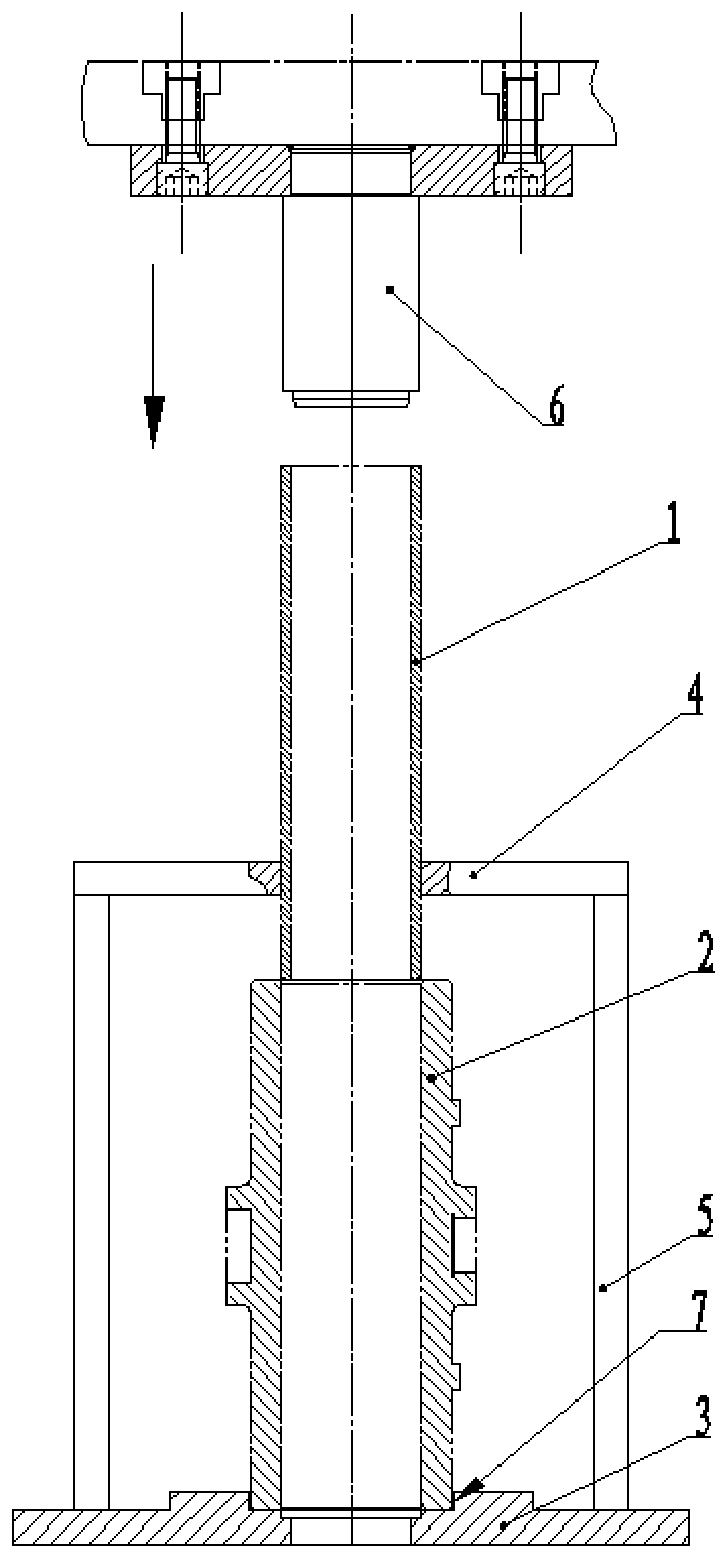

Embodiment 1

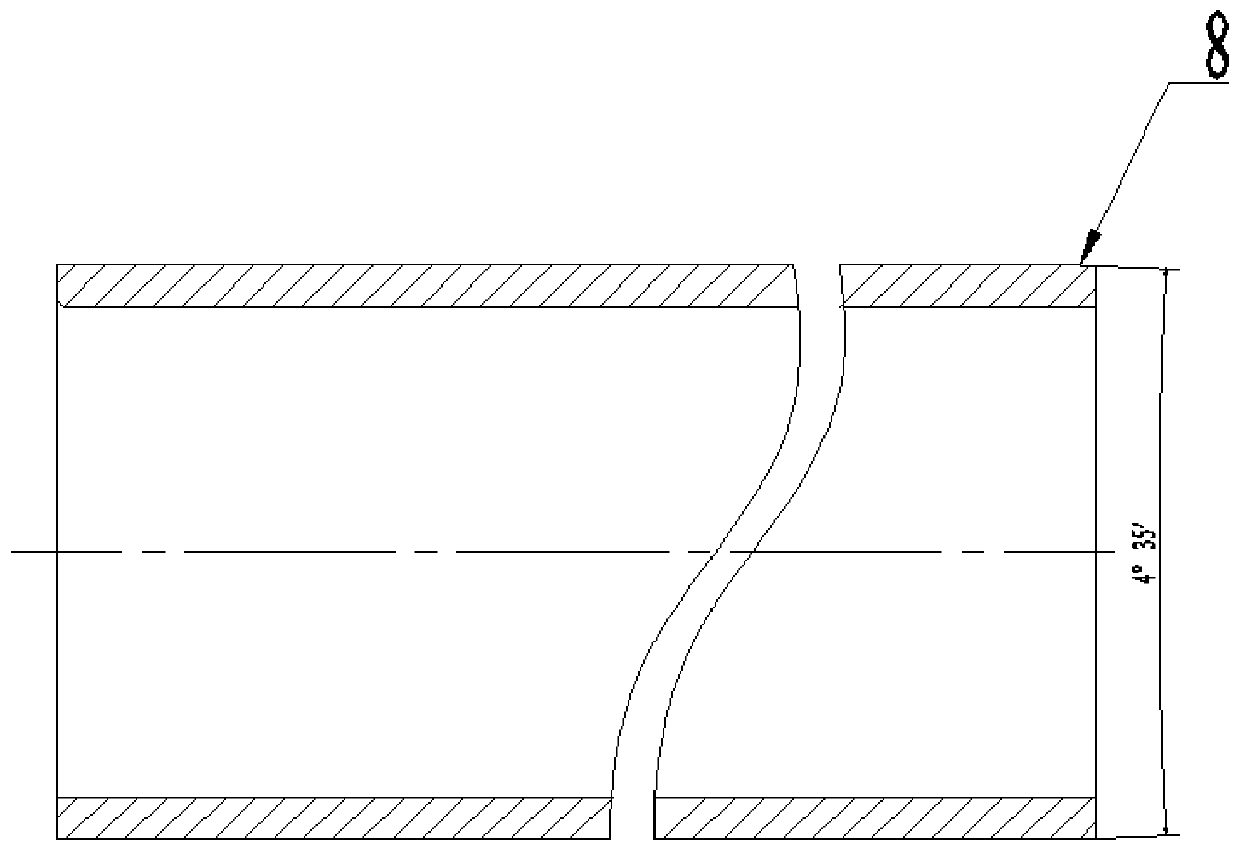

[0035] Embodiment 1, the inner hole diameter is 81.98mm rotating drug chamber 2 and the outer diameter is 82.23mm inner bore 1 is assembled. The inner bore 1 with an outer diameter of 82.28 to 82.23mm shrinks in diameter by 0.12 to 0.13mm after being cooled by liquid nitrogen; the rotating drug chamber 2 can be calculated according to the formula:

[0036]

[0037] It can be calculated how much the inner hole of the rotating drug chamber 2 can expand theoretically after heating, where α is the change of the outer diameter or inner diameter, K is the linear expansion coefficient of the material, D1 is the diameter of the inner hole before heating, and T2 is the dry The required heating temperature set by the box, T1 is the room temperature before heating. In the case of a room temperature of 30°C, if the rotating drug chamber 2 is heated to 350°C, according to formula 1), it can be calculated that the diameter of the inner hole of the rotating drug chamber 2 after heating ca...

Embodiment 2

[0038] In the second embodiment, the rotating drug chamber 2 with an inner hole diameter of 81.9 mm and the inner bore 1 with an outer diameter of 82.2 mm are assembled. In the case of a room temperature of 30°C, if the rotating drug chamber 2 is heated to 350°C, the diameter of the inner hole of the rotating drug chamber 2 after heating can theoretically be enlarged by 0.29877mm, and the diameter of the inner bore 1 can theoretically be calculated according to formula 1). The shrinkage is about 0.1mm, so in theory, the rotating drug chamber 2 can be heated to 350°C to complete the assembly. Put the rotating drug chamber 2 into a QX841-2 drying oven and heat it to 350°C, and keep it warm for 3 hours, and put the inner chamber 1 in a liquid nitrogen tank for cooling treatment, and keep it warm for 3 hours; The hole actually expanded to 82.2mm, which was expanded by 0.3mm, and the outer diameter of the inner bore 1 actually shrank to 82.1mm after cooling, which was reduced by 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com