A fixture device and clamping method for FMC motor shaft processing

A fixture device and motor shaft technology, which is applied in the field of numerical control, can solve the problems that only horizontal milling machines can be used for non-U-shaped slot milling of ports, and cannot be used for non-U-shaped slot milling of motor shaft parts, so as to achieve stability , Protect the motor shaft and avoid over-clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

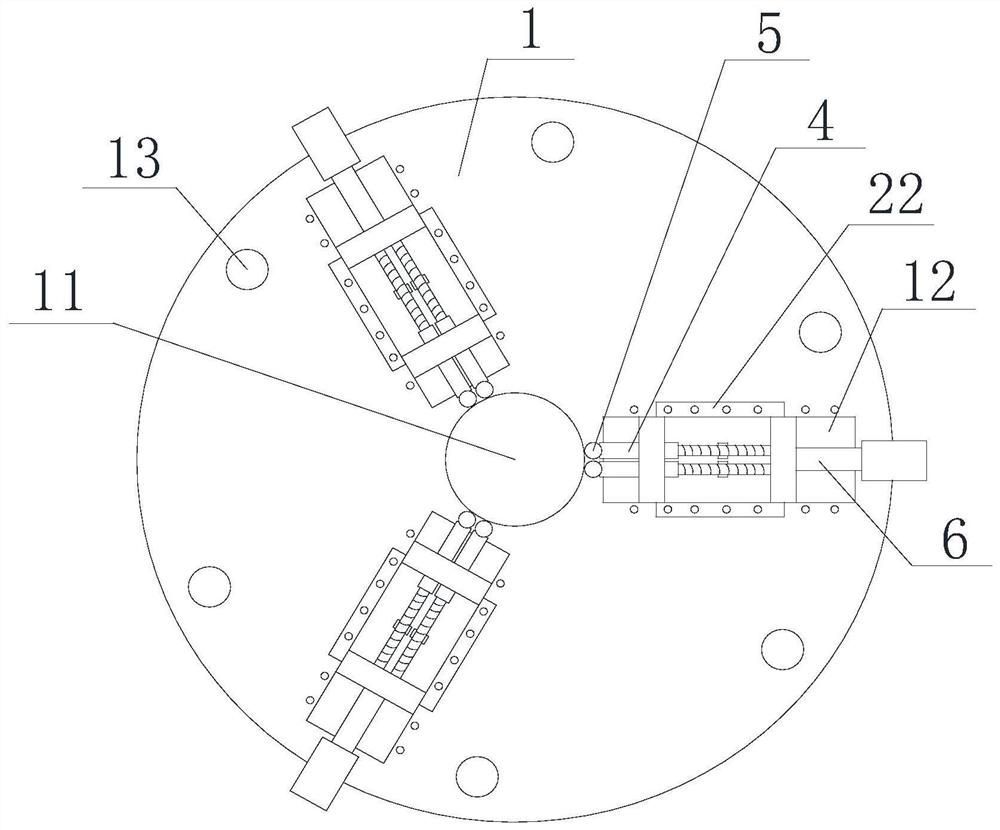

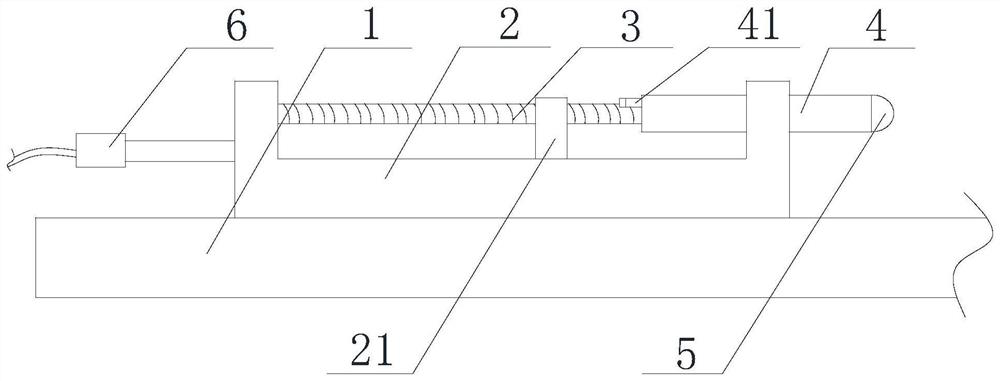

[0041] Such as figure 1 , figure 2 As shown, a fixture device used for FMC motor shaft processing includes a fixed plate 1, and a plurality of mounting holes 13 are arranged on the fixed plate 1. Installed on the workbench of the vertical milling machine, the upper end surface of the fixed disk 1 is provided with a positioning groove 11 at the center, the positioning groove 11 is a circular groove, and the upper end surface of the fixed disk 1 is outside the positioning groove 11 There are three slide grooves 12, the slide grooves 12 are dovetail grooves, the slide grooves 12 are arranged along the radial direction of the fixed disk 1, and the three slide grooves 12 are evenly arranged along the circumferential direction of the fixed disk 1. A clamping plate 2 is arranged in the chute 12, and two clamping rods 4 are arranged at the inner end of the clamping plate 2, and the end of the clamping rods 4 is provided with a limit ball 5 for clamping the motor shaft ; Also includ...

Embodiment 2

[0045] Such as figure 1 , figure 2 As shown, this embodiment is based on Embodiment 1, the clamping plate 2 is a U-shaped plate, two threaded rods 3 are vertically arranged on one side wall of the U-shaped plate, and two threaded rods 3 are arranged on the other side wall The through hole, the clamping rod 4 is penetrated in the through hole, the clamping rod 4 is a sleeve structure, and the clamping rod 4 is threadedly connected with the end of the threaded rod 3 .

[0046] The working principle of this embodiment is as follows:

[0047] Insert one end of the motor shaft to be processed into the positioning groove 11, so that the end of the motor shaft to be processed faces upward; drive the cylinder 6, so that the clamping plate 2 moves toward the motor shaft in the chute 12, and when the limit ball 5 When the motor shaft is about to be in contact with or just in contact with the motor shaft, the cylinder 6 stops, and the clamping rod 4 is manually adjusted, and the clamp...

Embodiment 3

[0049] Such as figure 1 , figure 2 As shown, this embodiment is based on Embodiment 2, and the end of the clamping rod 4 away from the limit ball 5 is provided with an operating handle 41; the bottom of the U-shaped plate is provided with a support plate 21 for supporting the threaded rod 3; The top of the support plate 21 is provided with an arc-shaped groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com