Laminated assembly structure and method of quartz crystal resonator and resonator

A quartz crystal and assembly structure technology, applied in the field of resonators, can solve the problems of limited acceleration sensitivity, improve the cost and stability of crystal oscillators, etc., and achieve the effect of simple assembly method, easy operation, and guaranteed accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0060] As a specific embodiment of the quartz crystal resonator stack assembly method provided by the present invention, it also includes the following steps:

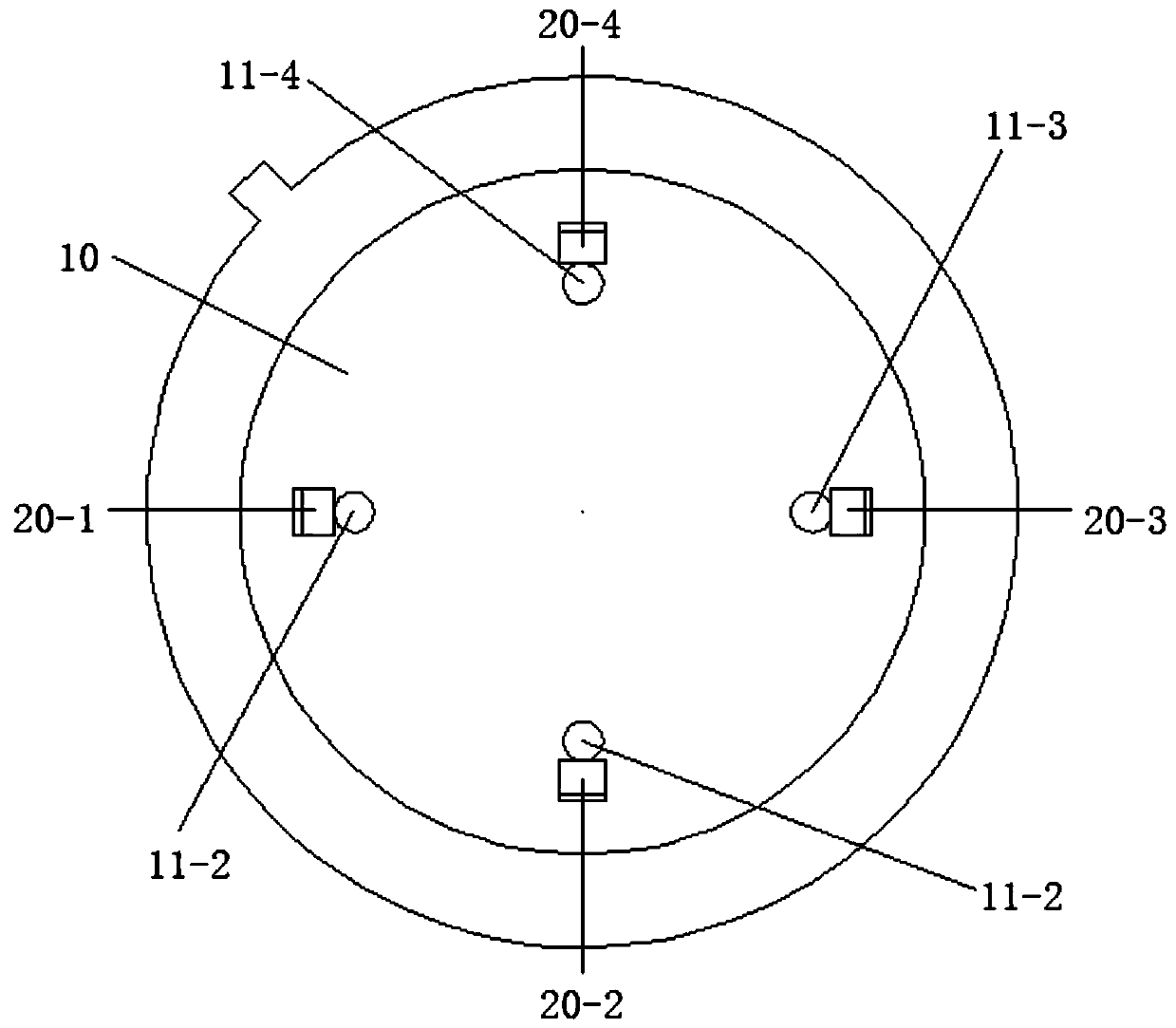

[0061] A holding claw 21 for holding the buffer wafer 30 is preset on the spring plate 20 .

[0062] The step of connecting the buffer electrode region 31 of the buffer wafer 30 to the spring plate 20 includes:

[0063] Dispense the conductive glue on the claw 21 of the spring plate 20, place the buffer wafer 30 on the claw 21, and connect with the conductive glue.

[0064] As a specific embodiment of the quartz crystal resonator stack assembly method provided by the present invention, it also includes the following steps:

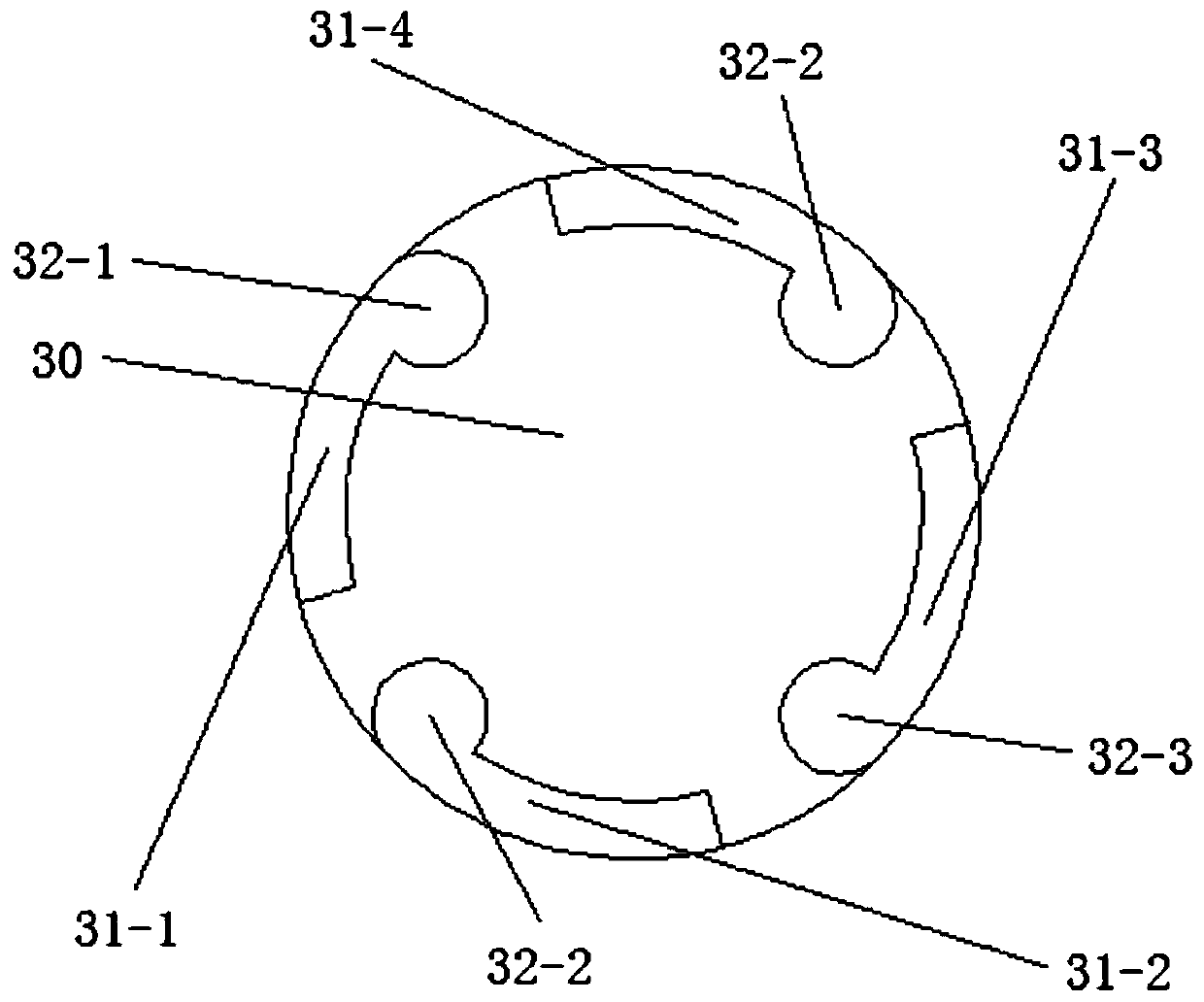

[0065] A connection point 32 extending to the inner side of the edge of the buffer wafer 30 is preset in the buffer electrode region 31 .

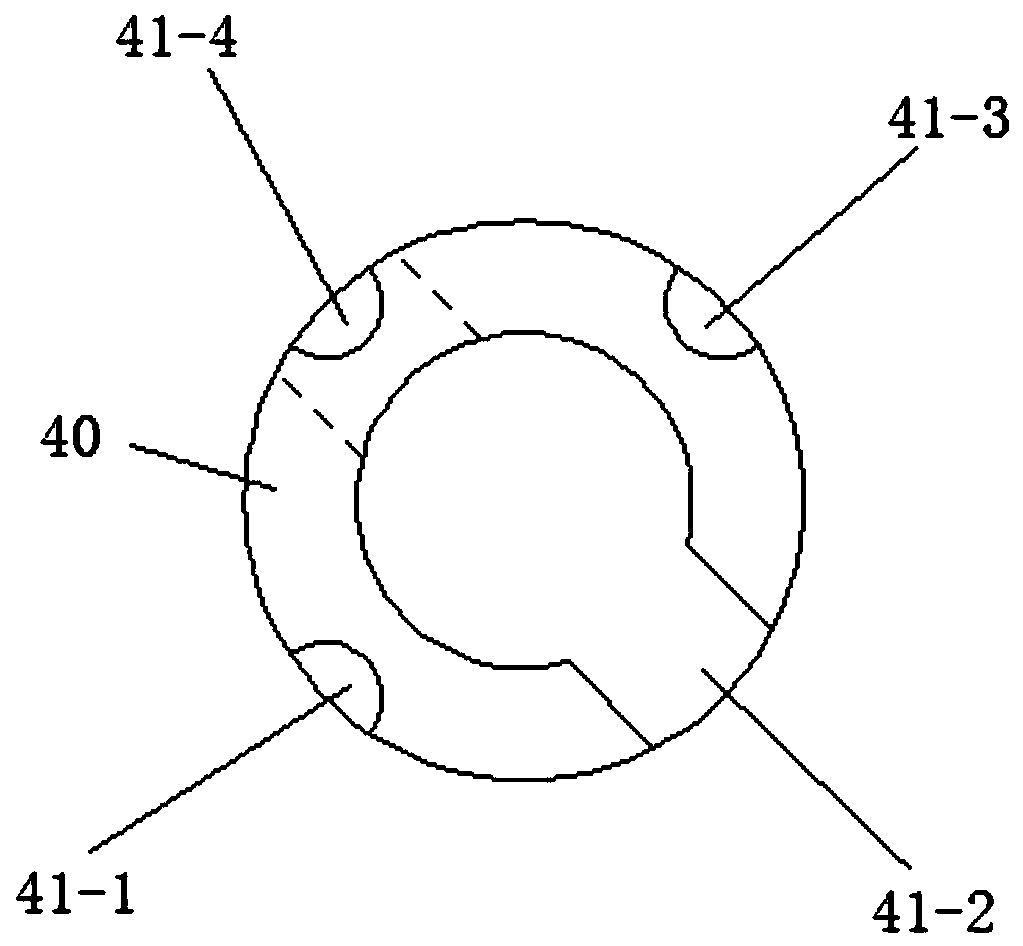

[0066] The step of connecting the output electrode region 41 of the frequency output wafer 40 to the buffer electrode region 31 of the buffer wafer 30 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com