Power conversion device and heat dissipation system thereof

A technology of power conversion device and heat dissipation system, which is applied in the field of rail transit, and can solve problems such as large module power loss, heat accumulation, power module of power conversion device, and high failure rate of electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

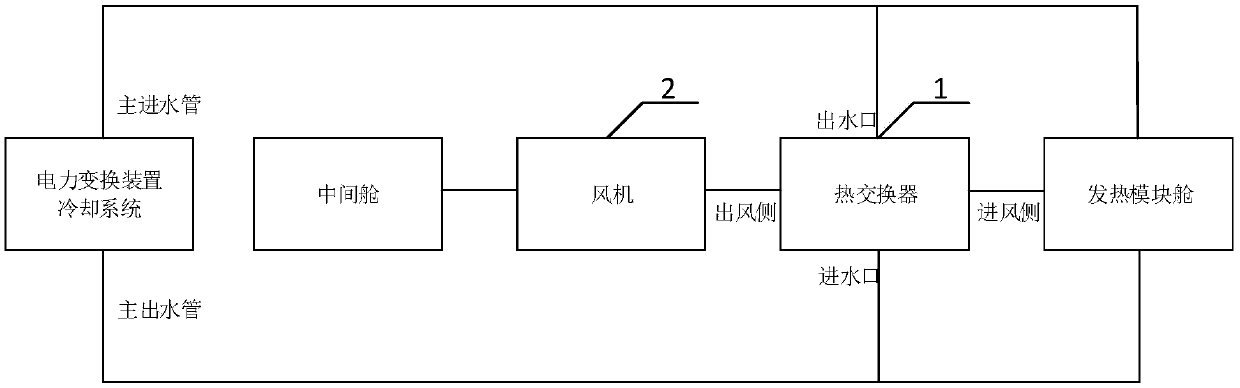

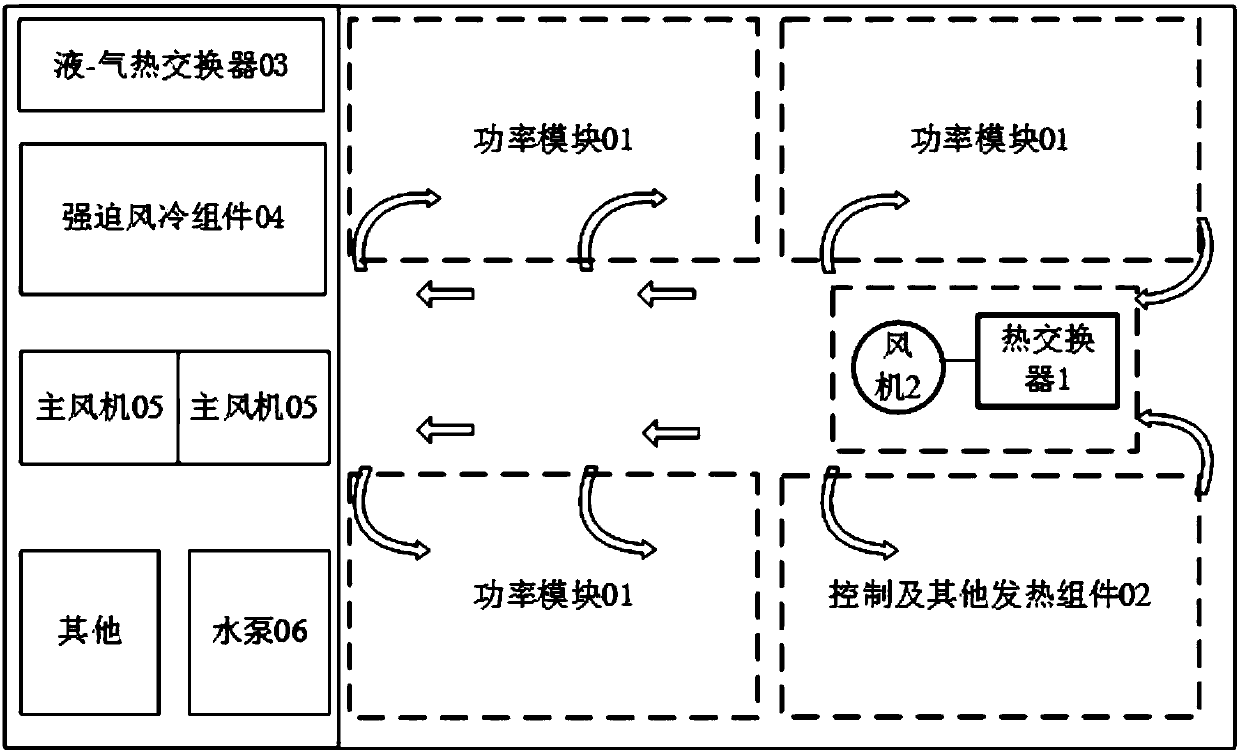

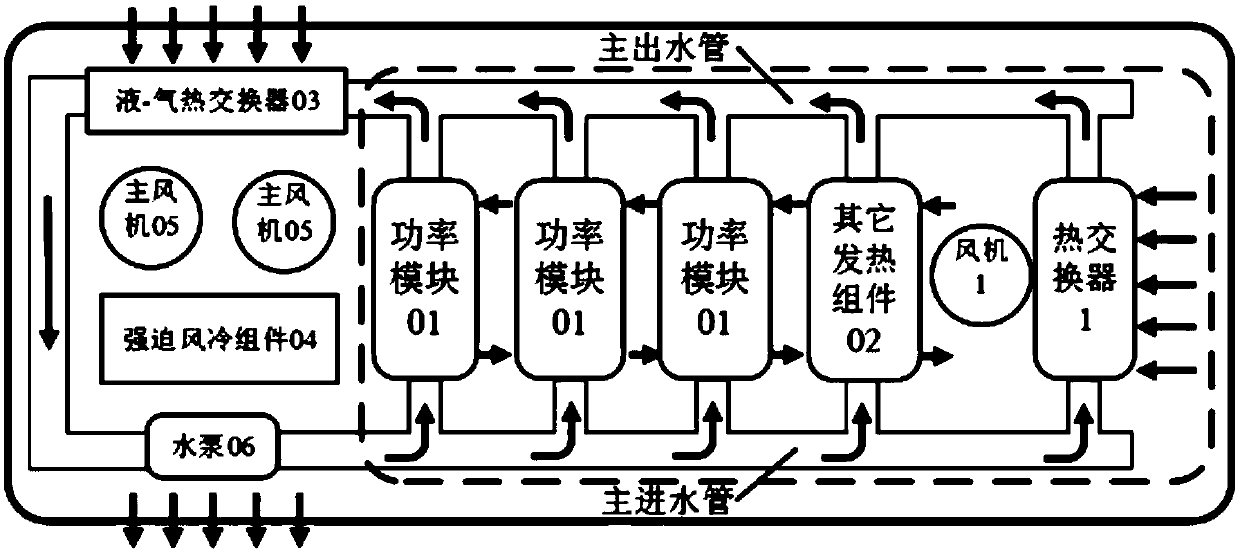

[0033] The core of the present invention is to provide a heat dissipation system for a power conversion device. The fan stirs the air in the electrical cabin to make it flow, avoiding the occurrence of local hot spots in the electrical cabin, and at the same time realizes the external heat exchange of the heat in the electrical cabin through a heat exchanger. , which greatly improves the operating temperature in the electrical compartment of the power conversion device, and improves the life and reliability of the electrical components inside the power conversion device; another core of the present invention is to provide a power conversion device including the above-mentioned heat dissipation system.

[0034] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com