Battery cell winding device and method

A winding device and cell technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of easy deviation of the diaphragm, fluctuation of diaphragm tension, and long auxiliary time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

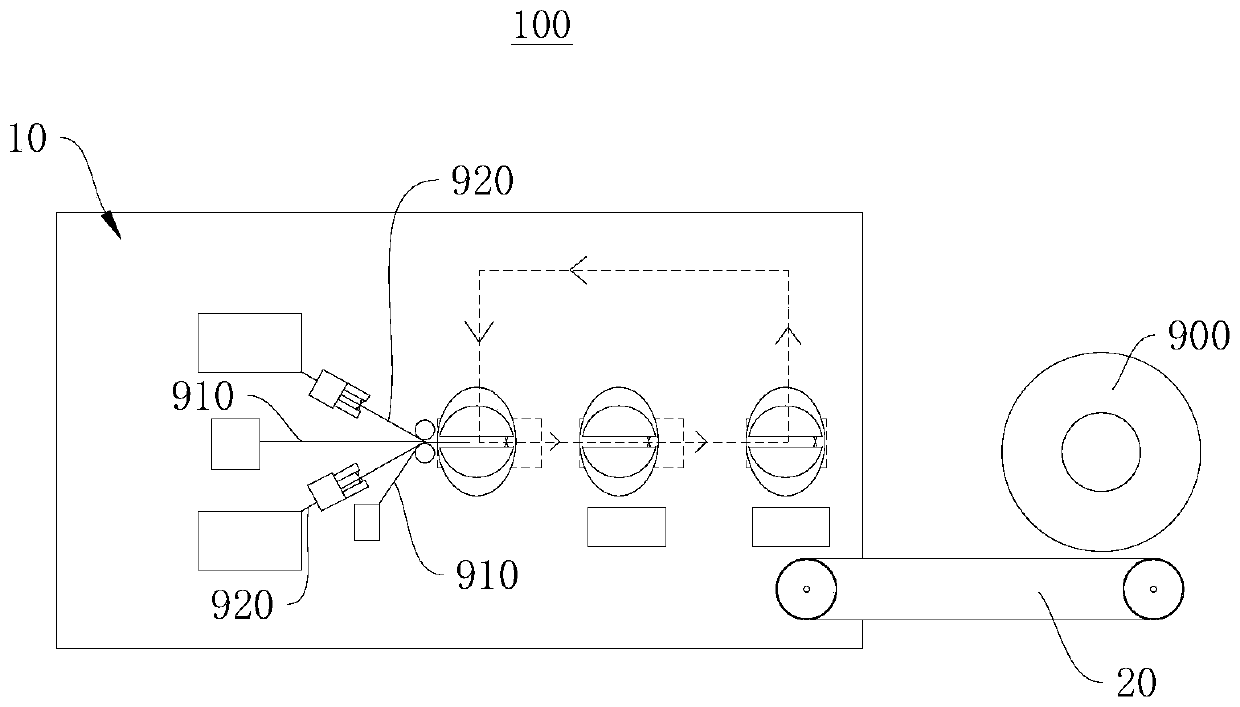

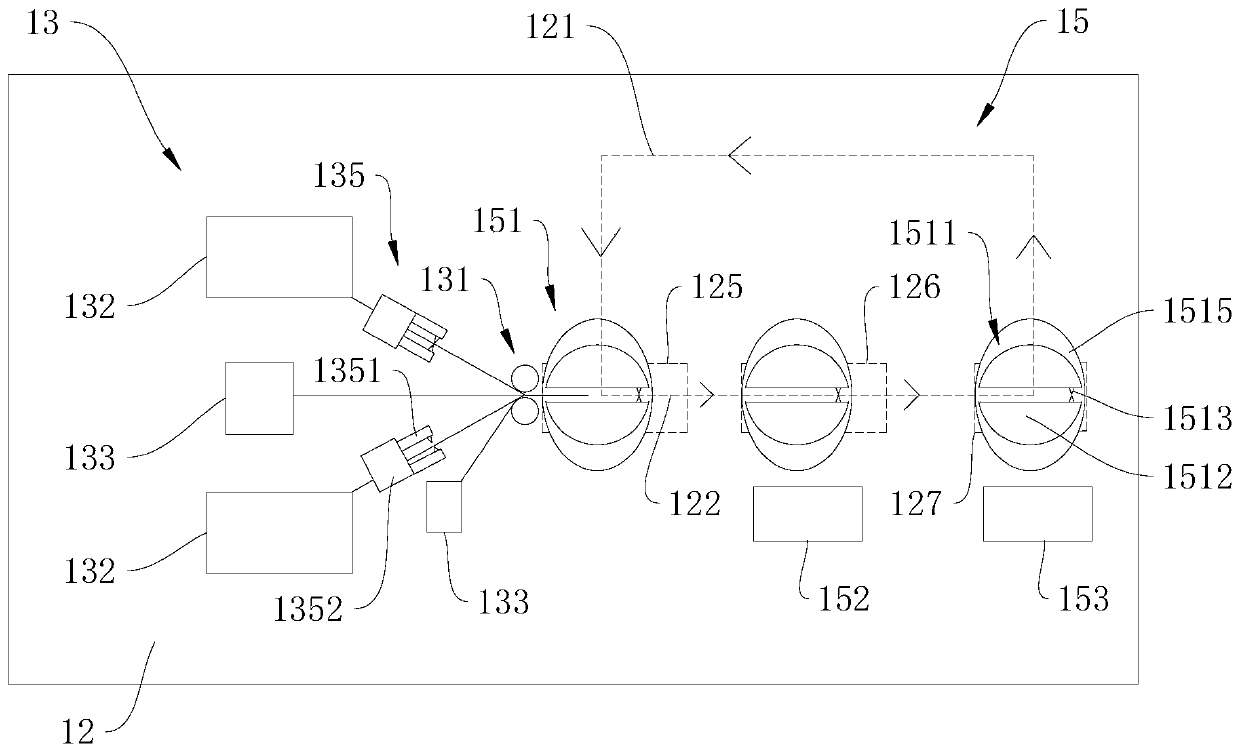

[0035] see figure 1 , figure 1 It is a schematic diagram of the structure of the cell winding device 10 applied to the cell production system 100 provided by the first embodiment of the present invention.

[0036] The first embodiment of the present invention provides a cell winding device 10, which has the characteristics of being able to continuously transport the separator 910, and having high winding efficiency and winding quality. The cell winding device 10 can be applied to a battery production device or a battery production line, etc. Of course, the cell winding device 10 can also be used independently.

[0037] Wherein, taking the cell winding device 10 applied to the battery production device as an example, the cell production system 100 includes the cell winding device 10, which is wound by the cell winding device 10 to form a winding core 900, of course, the battery The core production system 100 may also include a production transmission mechanism 20, which is di...

no. 2 example

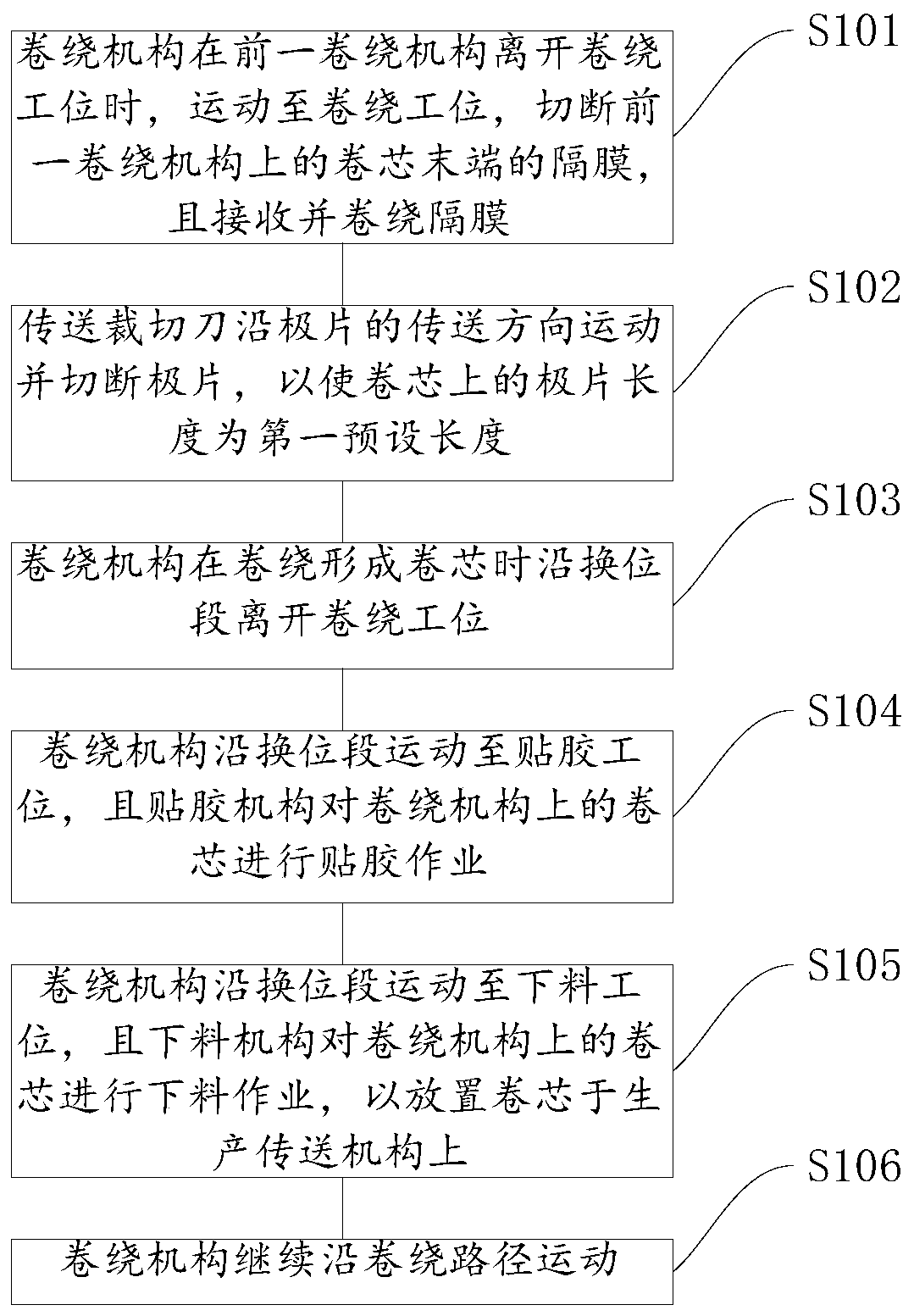

[0071] see image 3 , image 3 It is a schematic flow chart of the cell winding method provided by the second embodiment of the present invention.

[0072] The battery winding method is applied to the battery winding device 10. The basic principle and technical effects of the battery winding device 10 are the same as those of the above-mentioned embodiments. For a brief description, the parts not mentioned in this embodiment are as follows: Reference may be made to the corresponding content in the foregoing embodiments.

[0073] The cell winding method includes:

[0074] Step S101: the winding mechanism 151 moves to the winding station 125 when the previous winding mechanism 151 leaves the winding station 125, cuts off the diaphragm 910 at the end of the winding core 900 on the previous winding mechanism 151, and receives and The membrane 910 is wound.

[0075] In this way, after the previous winding mechanism 151 winds to form the winding core 900 and leaves the winding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com