Base pile pitching type single-pile pile stabilizing frame and pile sinking method

A single pile and stabilizing pile technology, applied in sheet pile wall, building, foundation structure engineering, etc., can solve the problem that the relative position error of the pile top cannot meet the design, the pile position deviation control cannot meet the requirements, the construction environment and climatic conditions are poor, etc. problems, to achieve the effect of convenient precision adjustment, saving pile driving time, and convenient adjustment and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

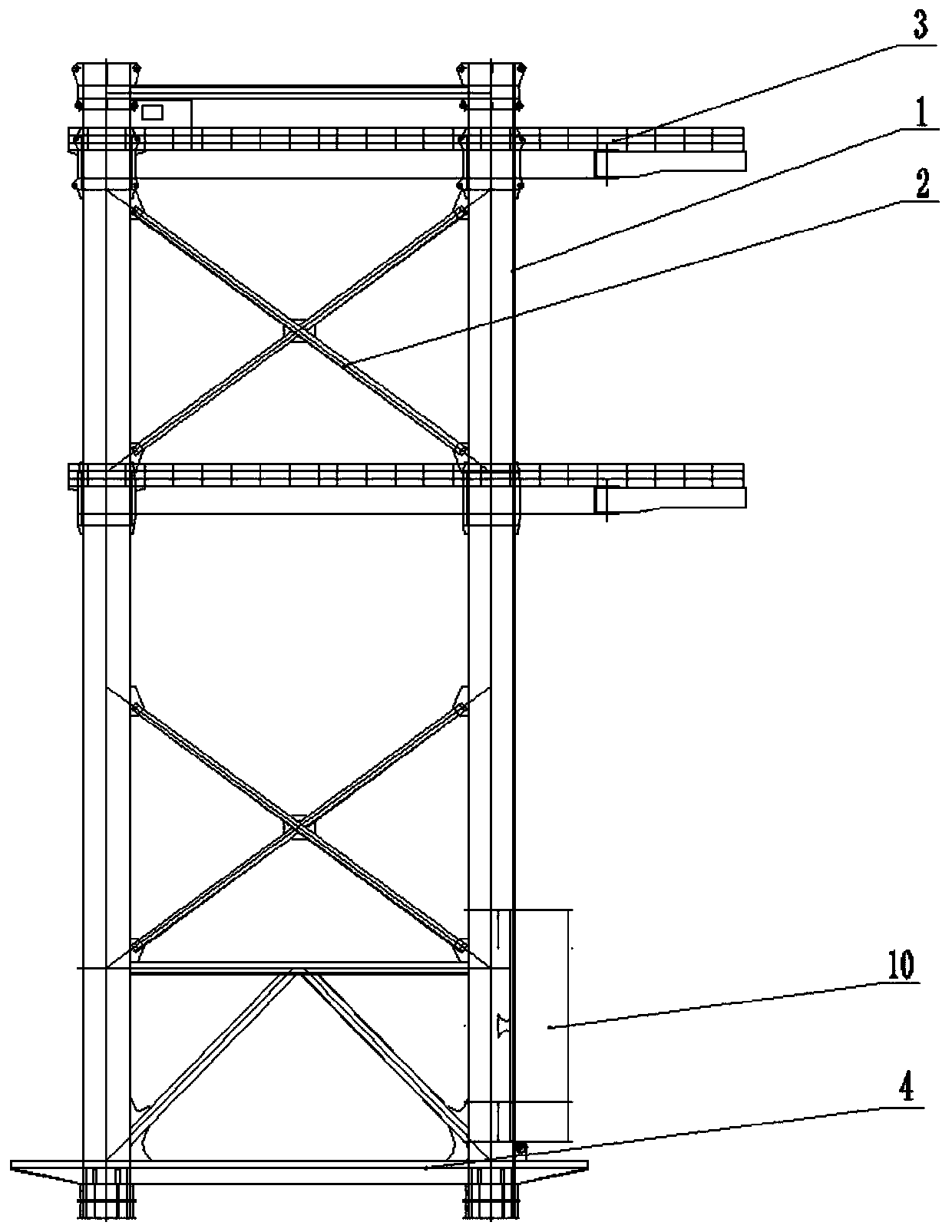

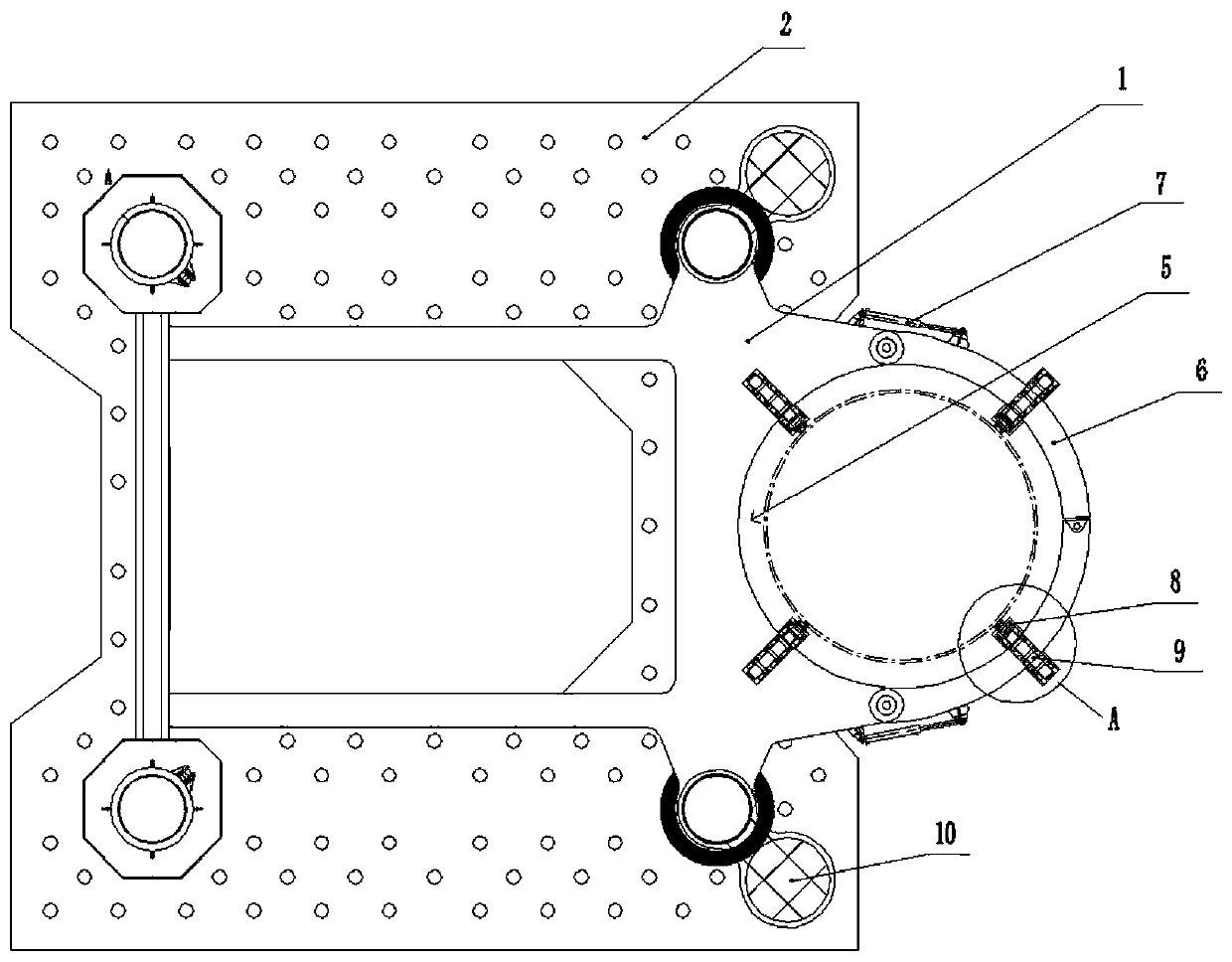

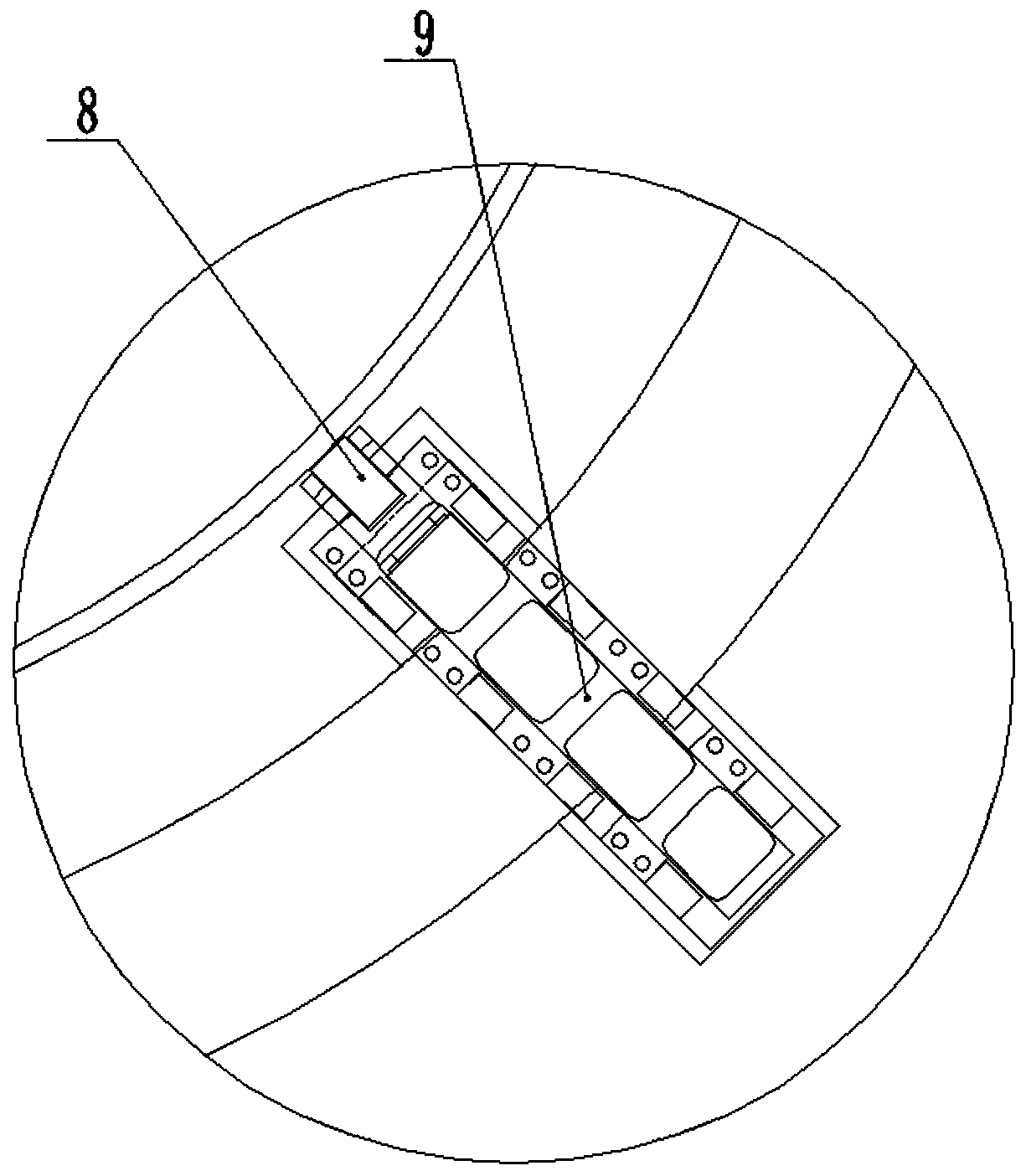

[0038] A single-pile stabilizing frame with piles inserted at the bottom of the base, including a pile-stabilizing truss. The pile-stabilizing truss is mainly composed of a number of vertical support columns 1, and the support columns 1 are connected by reinforcing braces 2 to form a main body of the pile-stabilizing truss. Part, the support column 1 is provided with a hollow cylinder cavity, the hollow cylinder cavity is used for the supporting positioning pile to be worn, the positioning pile is installed in the hollow cylinder cavity and the bottom of the positioning pile is fixed in the seabed;

[0039] Several pile-stabilizing platforms 3 are installed up and down in the middle and upper part of the pile-stabilizing truss, and anti-settling plates 4 are fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com