Water filling type rubber dam sand scouring and discharging system used for silting preventing behind long piled wharf

A technology for high-piled wharfs and rubber dams, which is applied in water conservancy projects, river regulation, sea area projects, etc., can solve the problems of large manpower, material and financial resources, long dredging time, inconvenience in construction, etc. Ease of getting the effect of shipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the invention is described in further detail:

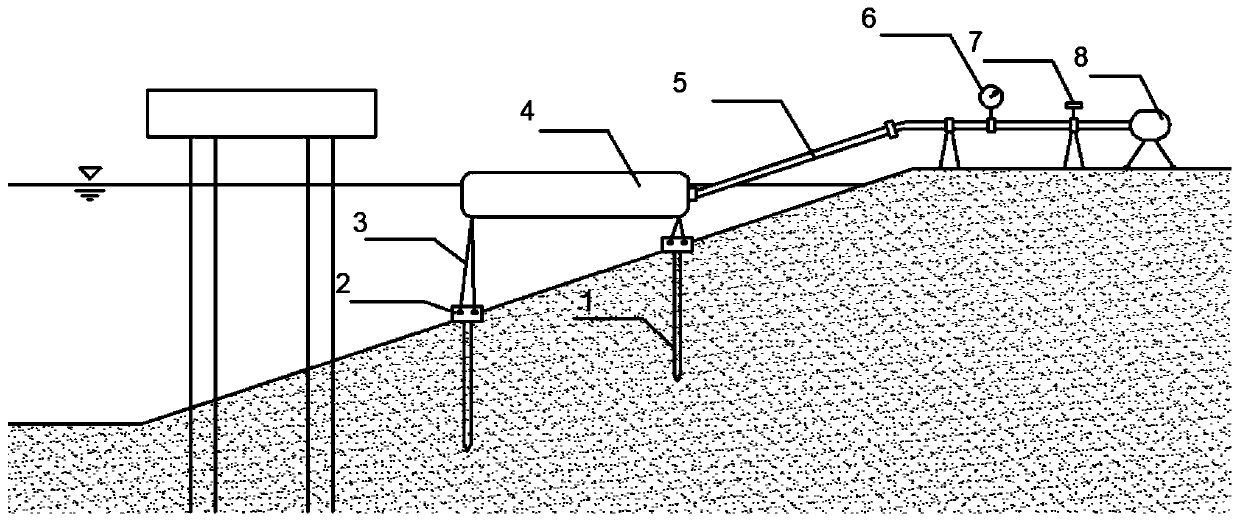

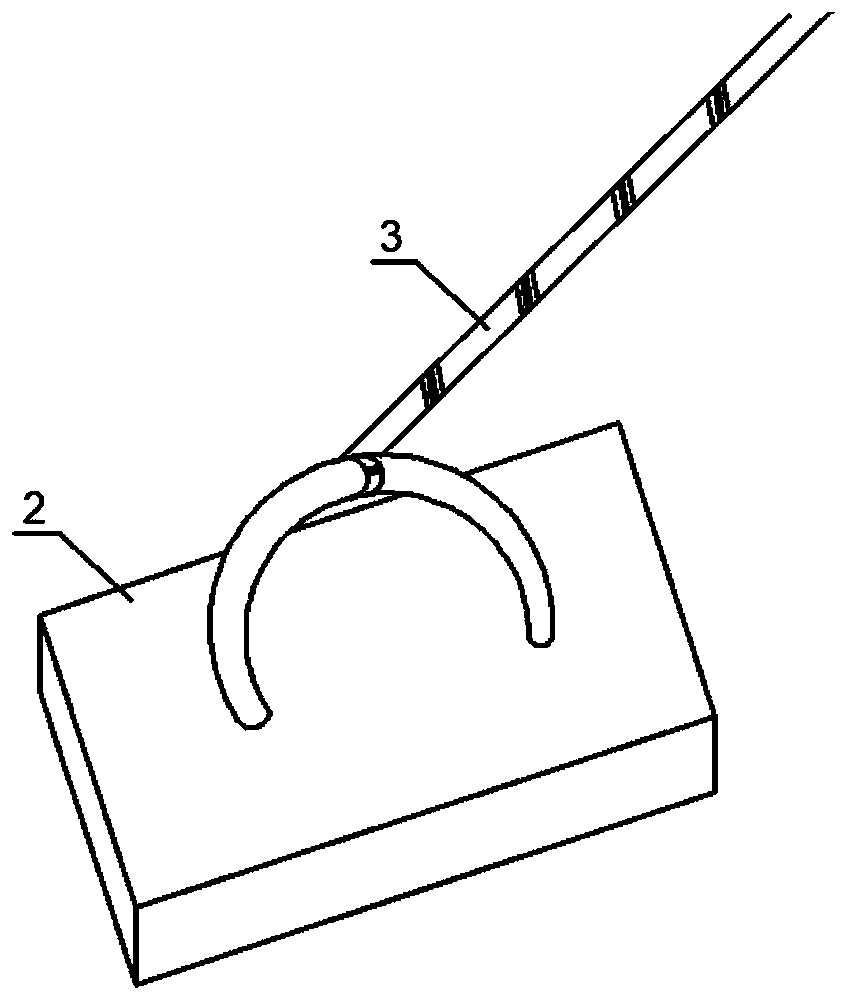

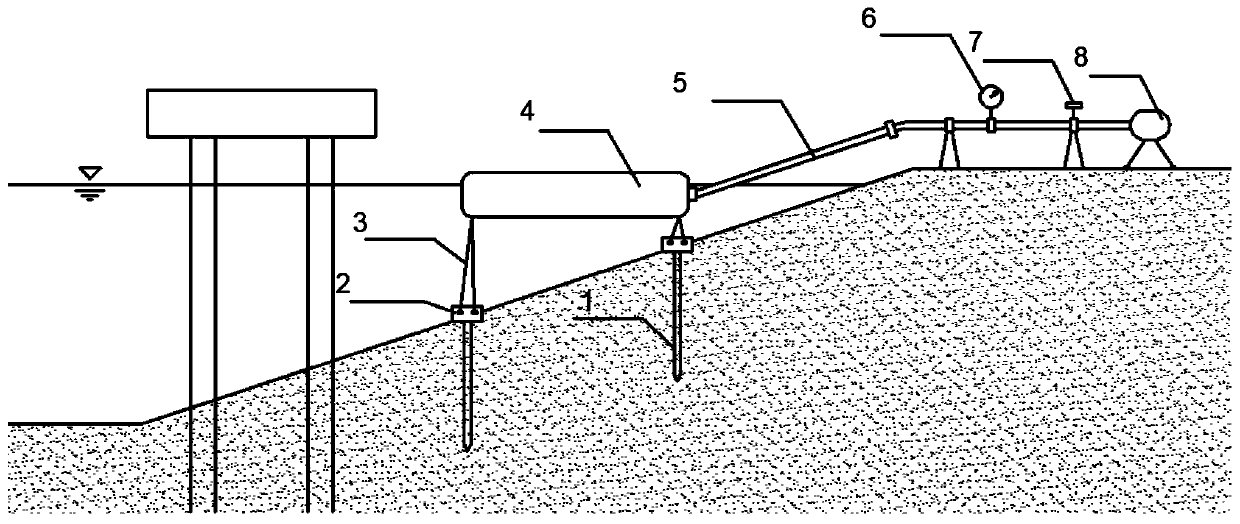

[0022] Such as figure 1 Shown is a water-filled rubber dam flushing and sand-discharging system for silting prevention at the rear of a high-pile wharf according to the present invention, including an anchor rod 1, a bottom plate 2, a fixed anchor 3, a water-filled rubber dam 4, and a water-filled pipeline 5 , water pressure gauge 6, water filling valve 7, and water pump 8. The anchor rod 1 is fixed on the bottom bed, the bottom plate 2 is arranged on the top of the anchor rod 1, the fixed anchor 3 connects the bottom plate 2 and the water-filled rubber dam 4, the water-filled pipeline 5 connects the water-filled rubber dam 4 and the water pump 8, and the water-filled pipeline 5. A water pressure gauge 6 and a water filling valve 7 are arranged near the water pump 8.

[0023] The anchor rods 1 take the water-filled rubber dam 4 as the axis of symmetry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com