Bundled fine dried noodle flush device and fine dried noodle packaging line

A kind of vermicelli and aligning technology, which is applied in the directions of packaging, transportation and packaging, the type of packaged items, etc., can solve the problems of low packaging quality and low flatness of the end face of the bundled noodle, and achieve the effect of improving stability and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

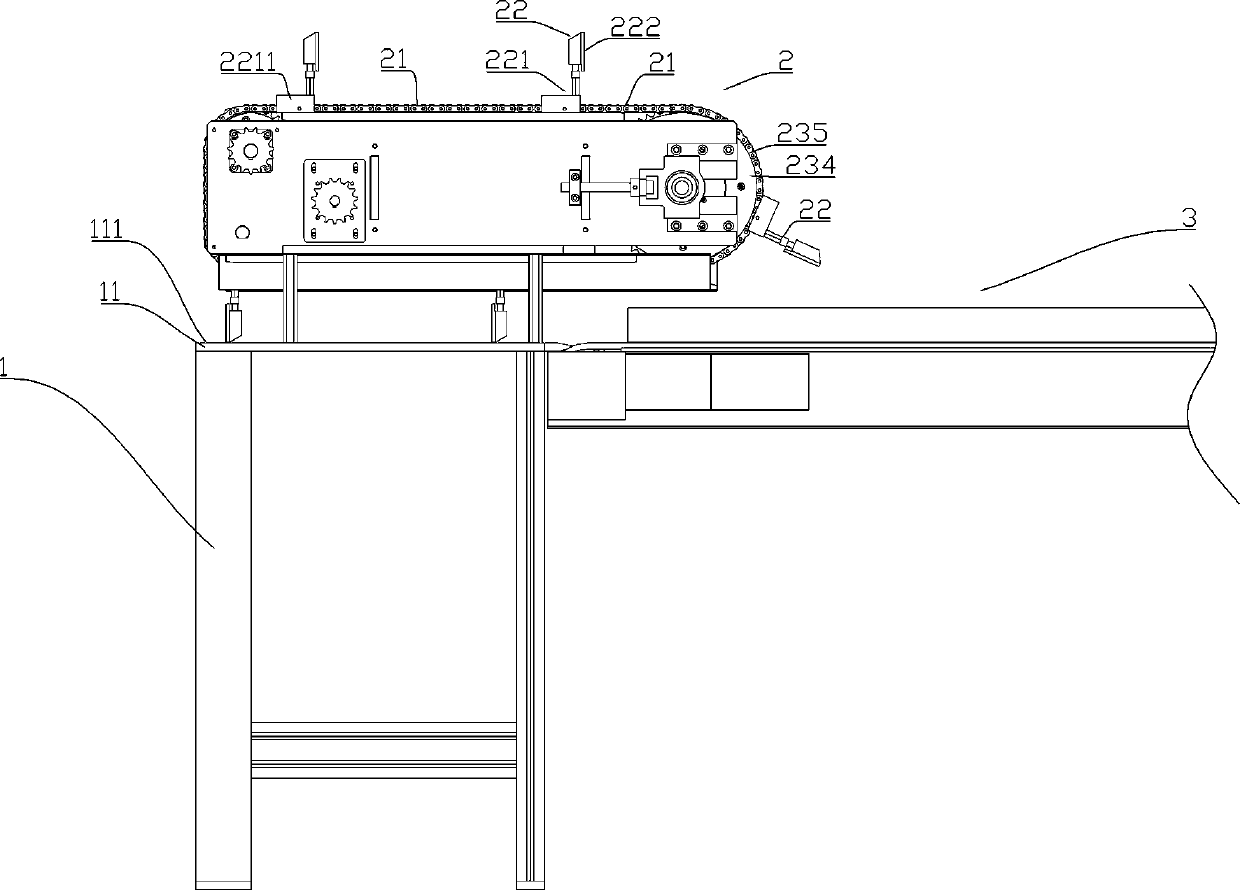

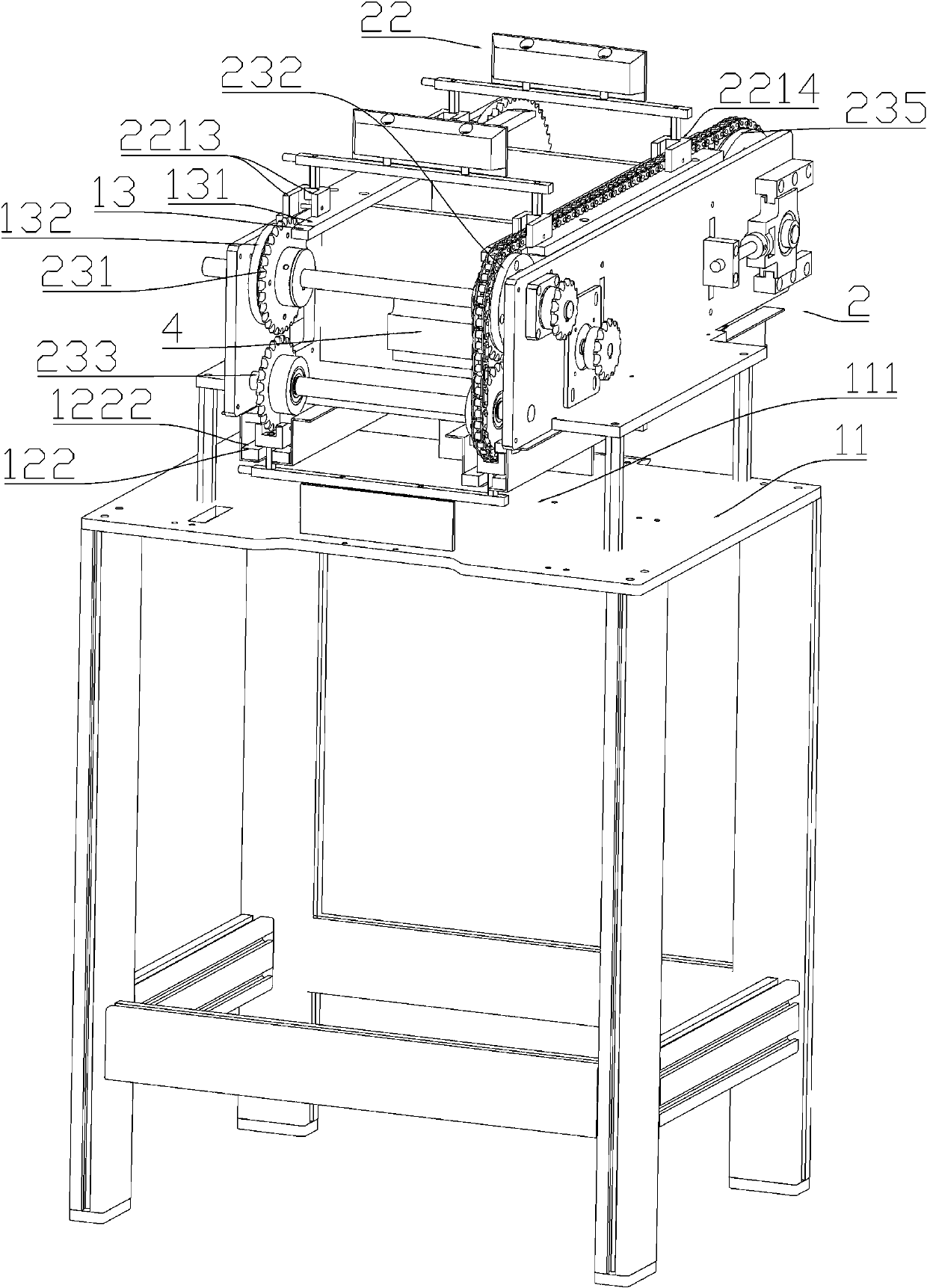

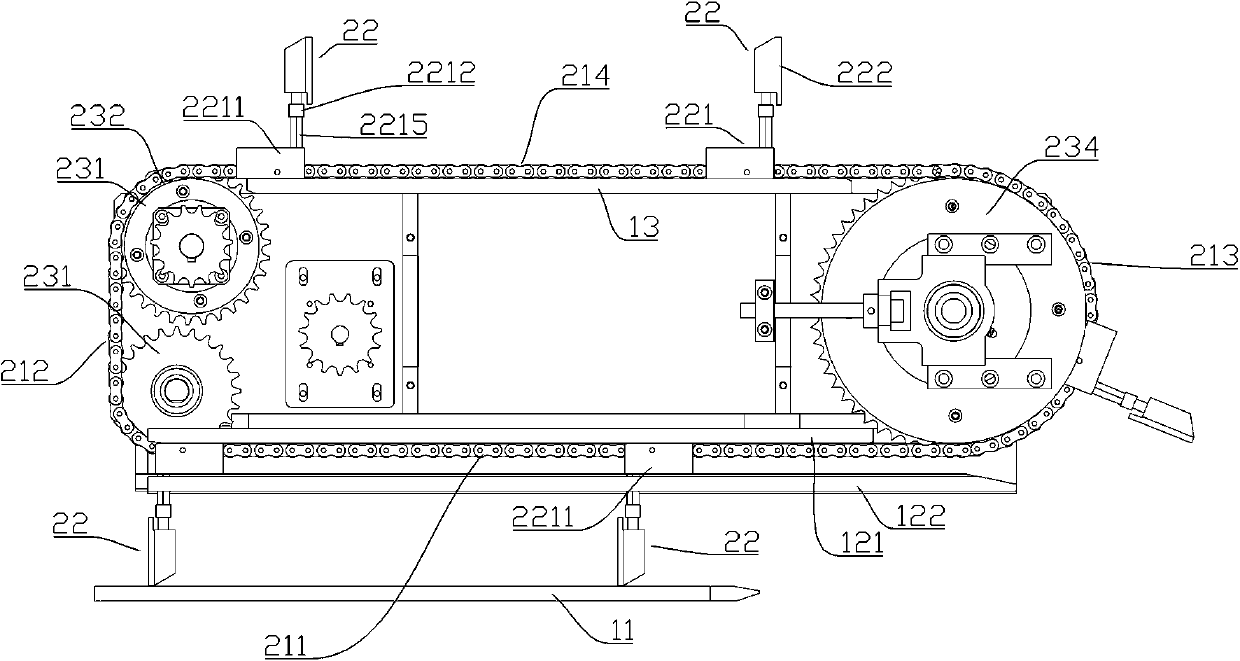

[0065] The dried noodle packaging line includes a dried noodle binding machine, a device for binding and aligning dried noodles, and a packaging machine. The noodles binding machine and packaging machine are prior art, and details will not be repeated here. In this embodiment, the device for binding and aligning dried noodles is mainly introduced.

[0066] Since the bundled dried noodles in groups are not neatly transported, which affects the subsequent packaging efficiency, it is necessary to arrange the bundled dried noodles in groups through a device for aligning the bundled dried noodles. The bundled dried noodles in groups in the present invention refer to at least two bundled dried noodles that are juxtaposed into one package. Group. The device for aligning the bundled dried noodles in this embodiment is used to make the end surfaces of bundled dried noodles flush in groups.

[0067] Such as Figure 1 to Figure 5 As shown, the device for bundling dried noodles includes ...

specific Embodiment 2

[0085] The specific embodiment 2 of the device for bundling dried noodles of the present invention, the difference between the device for bundling dried noodles in this embodiment and the above-mentioned specific embodiment is only that one working anti-rotation mating surface is provided.

specific Embodiment 3

[0086] Specific embodiment 3 of the device for bundling dried noodles of the present invention. The difference between the device for bundling and trimming dried noodles in this embodiment and the above-mentioned specific embodiments is only that: in this embodiment, the ring-shaped transmission chain is arranged on the lower side of the fixed bearing surface. There are two fixed bearing surfaces, and a support column avoidance channel for the support column to pass is formed between the two fixed bearing surfaces, and the plate body is arranged on the upper side of the fixed bearing surface. In other embodiments, the endless transmission chain can also be arranged horizontally, and at this time the endless transmission chain is in the horizontal plane. In other embodiments, the endless transmission chain can also be a transmission belt, and now the push plate can be fixed on the transmission belt. Of course, in other embodiments, the push plate can also be directly fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com