Specially-shaped batch steel transfer tool

A special-shaped steel and tool technology, which is applied in the field of batch transfer tools for special-shaped steel, can solve the problems of scratches on the surface of special-shaped steel and affect the appearance quality, and achieve the effects of preventing scratches, flexible and convenient transfer, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

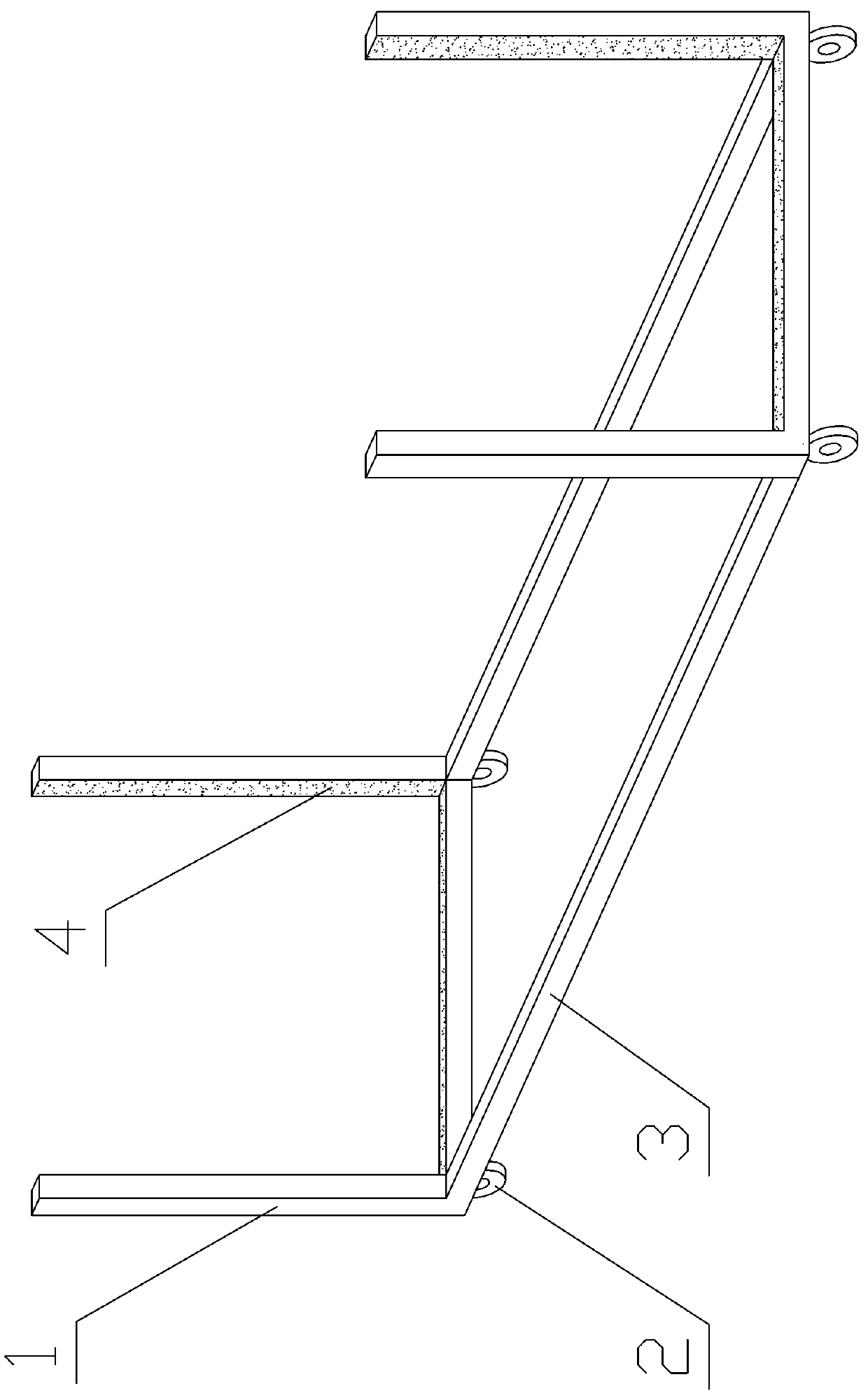

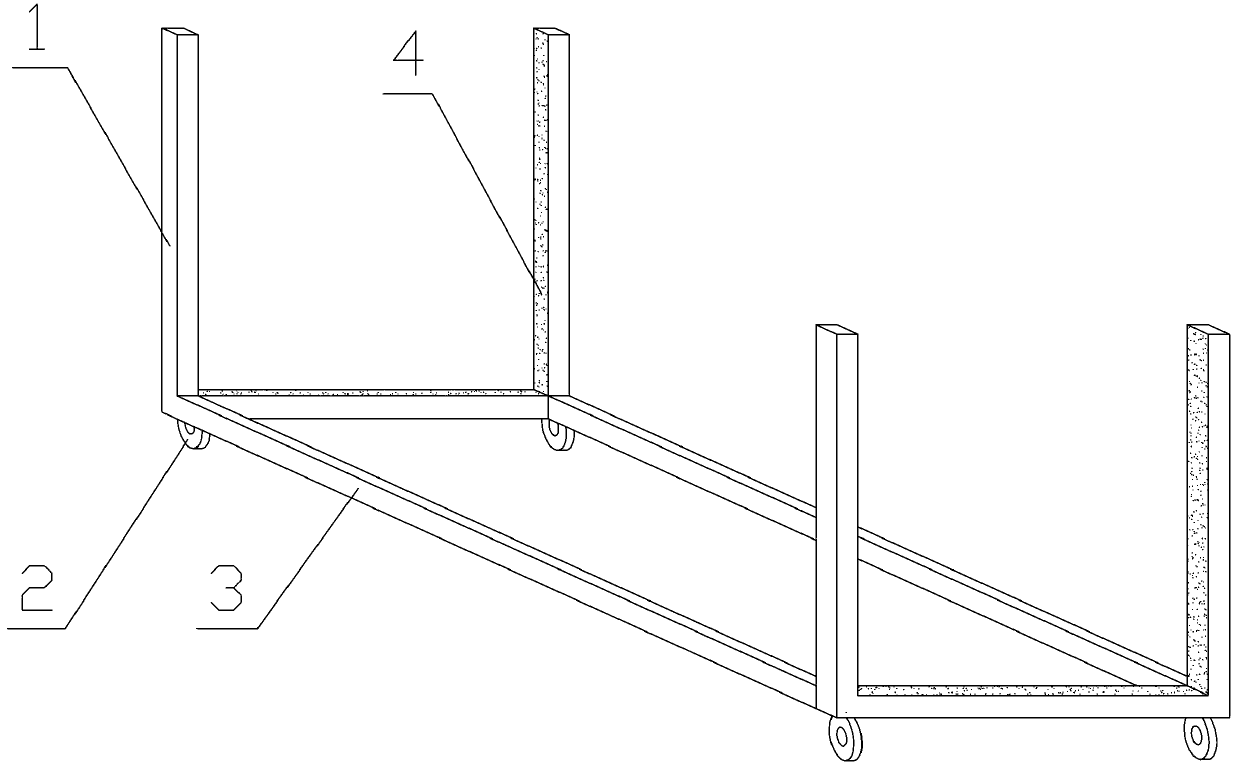

[0008] see figure 1 , the present invention is a batch transfer tool for special-shaped steel materials, which has two rectangular frames 1 arranged side by side. The bottom is equipped with traveling wheels 2, and the inner surface and the inner bottom surface of the rectangular frame are provided with an anti-scratch rubber layer 4.

[0009] The invention can simultaneously transfer large batches of special-shaped steel rods, the transfer is flexible and convenient, and at the same time, it can prevent the surface of the steel rods from being scratched, and has good application effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com