Photovoltaic module frame long edge shifting device fitted with punching machine and point riveting machine

A technology for photovoltaic modules and transfer devices, which is applied in the directions of feeding devices, positioning devices, storage devices, etc., to achieve the effect of reducing labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

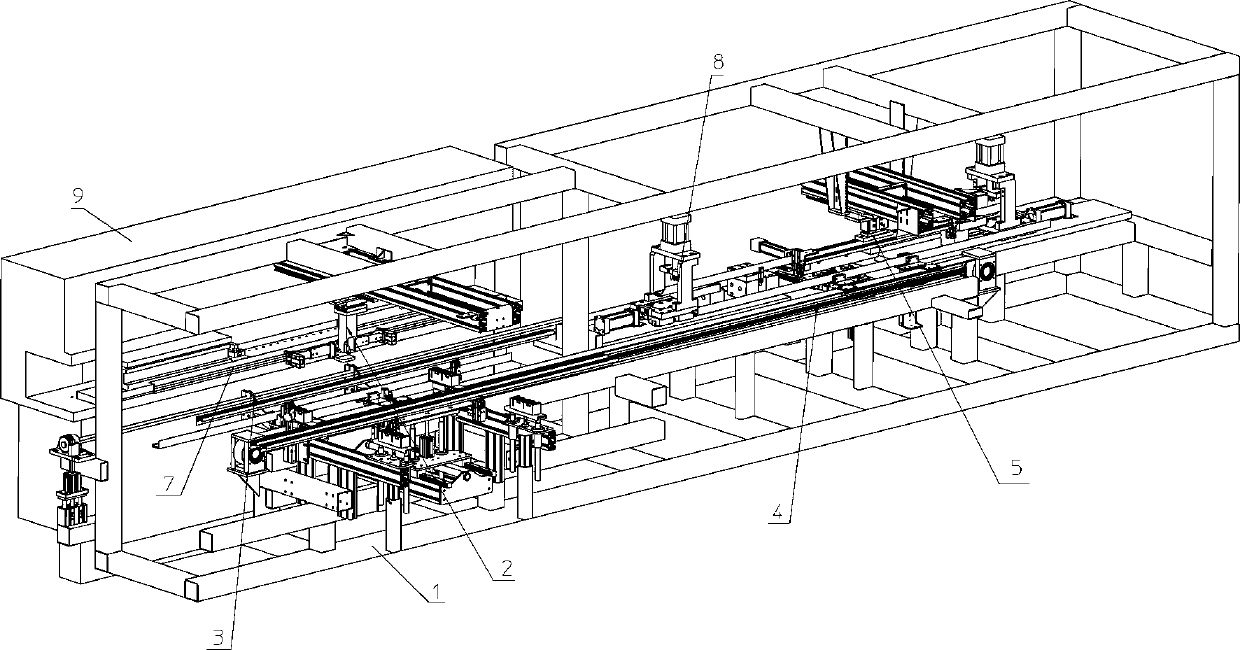

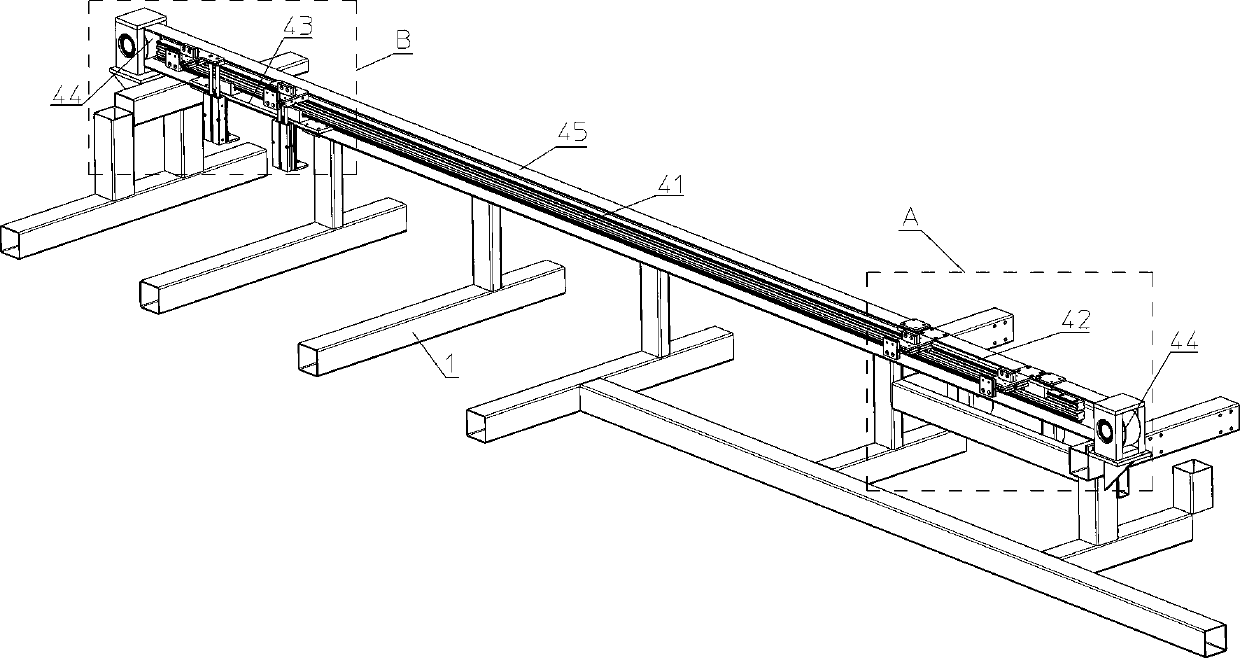

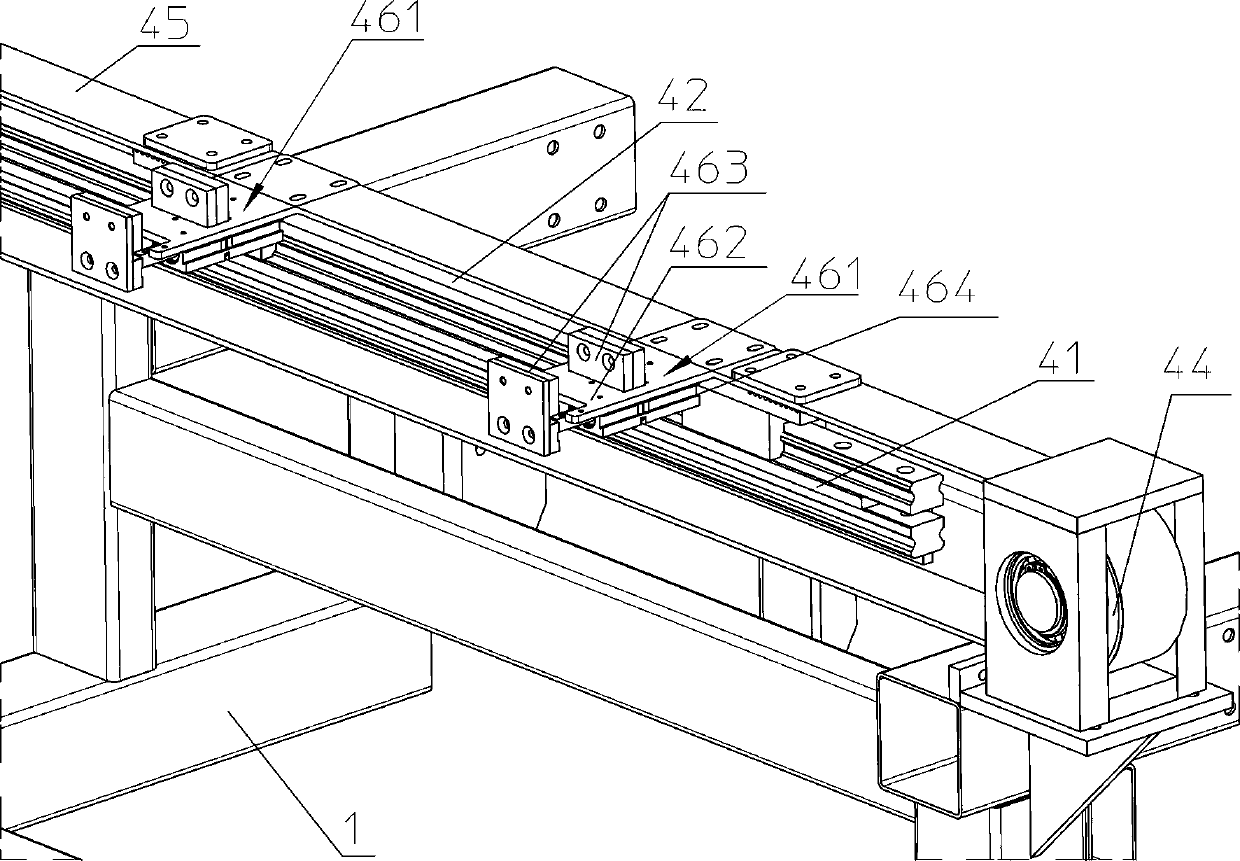

[0028] Such as figure 1 , figure 2 As shown, a photovoltaic module frame long side transfer device that cooperates with the punching machine and the riveting point machine includes: the long side 7 can be transferred from the punching and blanking station on the side of the punching machine 9 to the riveting point The transfer device 4 of the riveting point feeding station on one side of the machine 8, the punching feeding manipulator 2 capable of grabbing the long side 7 to be punched and sending it into the punching die of the punching machine 9, The punching machine 9 completes the punched long side 7 and transfers it to the punching and blanking manipulator 3 of the punching and blanking station, which can grab the long side transferred by the transfer device 4 to the riveting point loading station 7 and send it to the riveting poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com