Light splitting and taping integrated LED detection method and device

A detection method and detection equipment technology, applied in sorting and other directions, can solve the problems of large damage quantity and damage degree, failure to meet market requirements, poor material consistency, etc., to achieve strong operability, improve quality, and increase consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

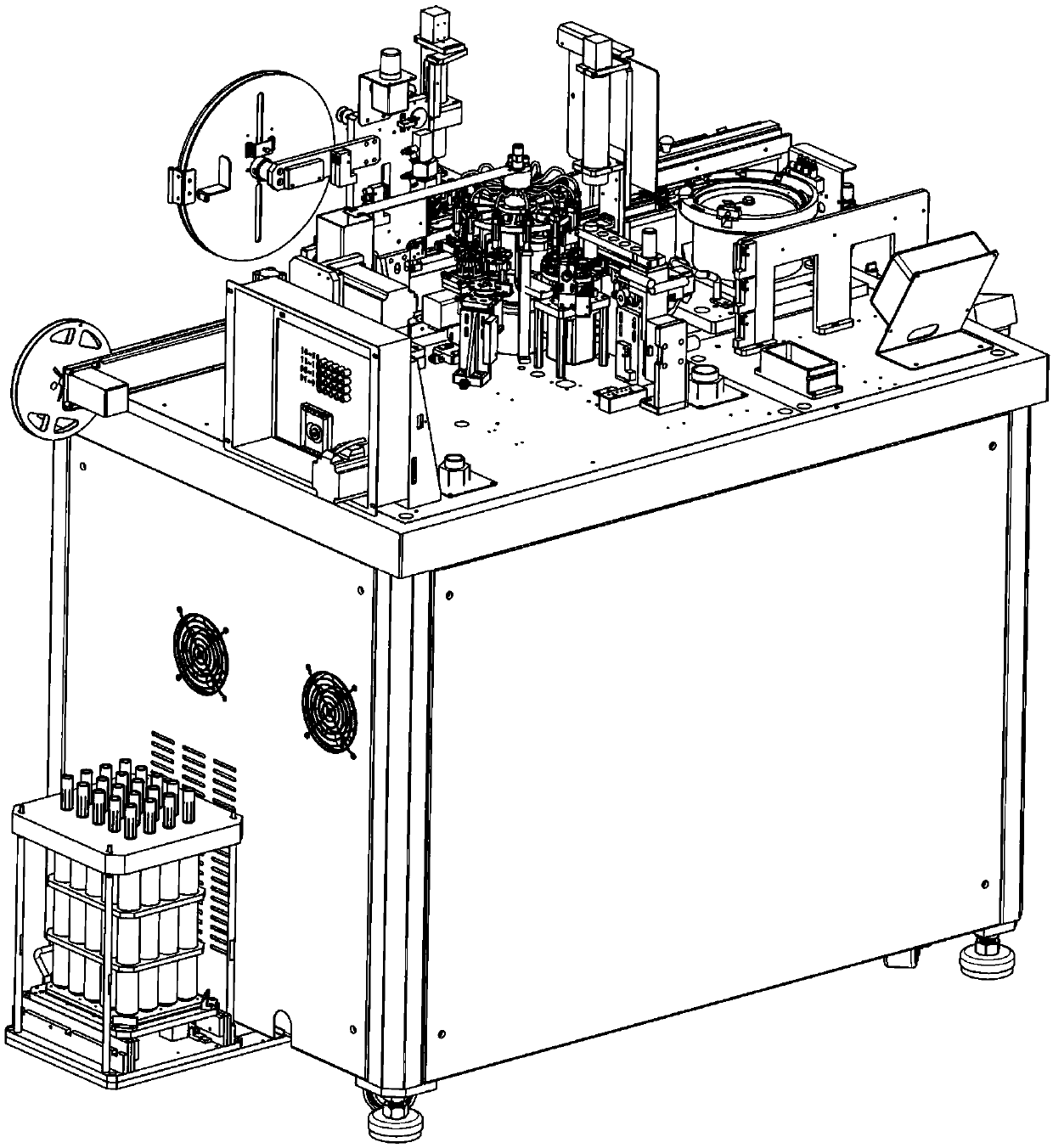

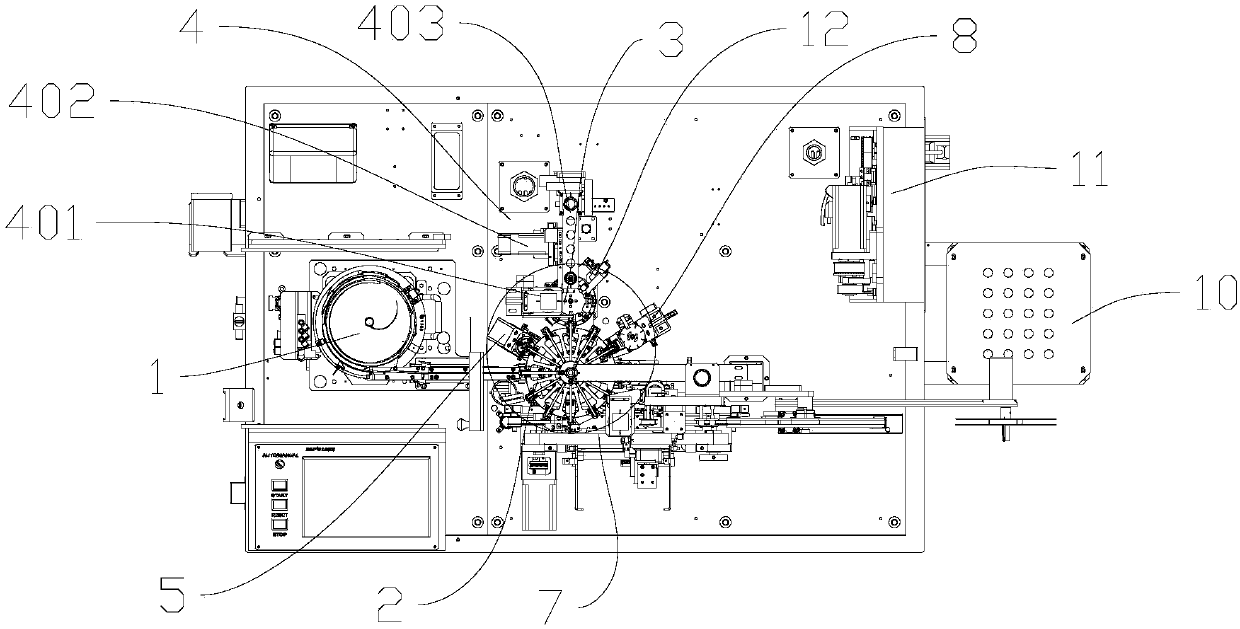

[0055] Such as Figures 1 to 5 A kind of LED detection equipment integrated with light splitting and braiding is shown, including:

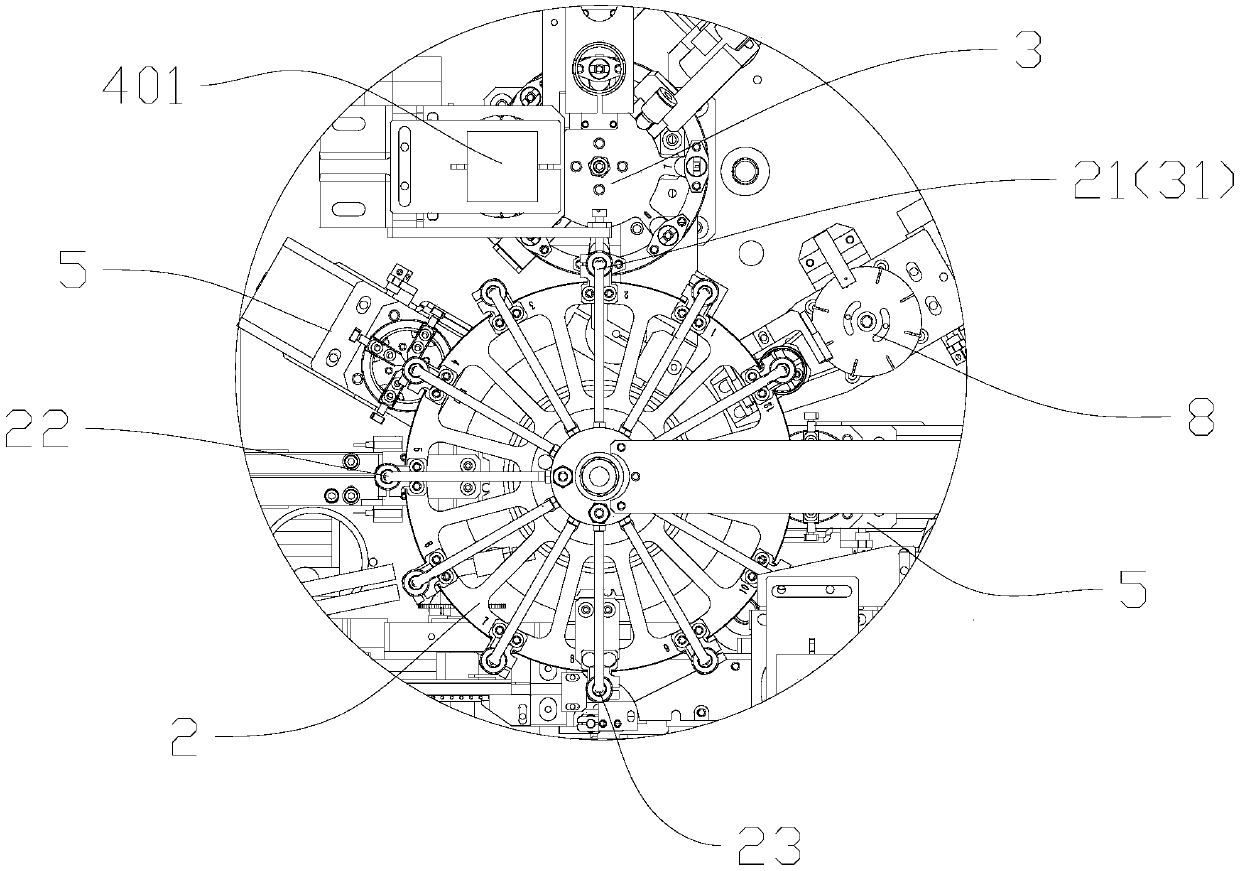

[0056] The first indexing plate 2, the first indexing plate 2 has a plurality of indexing stations, and the circumference of the first indexing plate 2 is provided with an exchange station 21, a feeding station 22, and a polarity rotation station , Taping station 23 and correction station;

[0057] The second indexing plate 3 is provided with a plurality of stations in cooperation with the first indexing plate 2, and each station cooperates with the station of the first indexing plate 2 to rotate on the same index, and exchange LEDs with it , the circumference of the second indexing disc is provided with an exchange station 31, a detection station and a classification blowing station;

[0058] The detection system 4 includes at least an image detection device 401 and a spectroscopic detection device 403, and the LEDs that are exchanged to the s...

Embodiment 2

[0085] Refer to attached Figure 6 As shown, the LED detection equipment with integrated spectroscopic braiding used in the detection method described in embodiment 1 is different from embodiment 1 in that the flat measuring mechanism is installed on the bottom side of the LED to form an integrated spectroscopic braiding at the bottom side. machine.

[0086] The rest of the components have the same structure as that of the LED testing device described in Embodiment 1.

Embodiment 3

[0088] A method for detecting LEDs with integrated light-splitting and braiding, comprising the steps of:

[0089] (1), transport the LED to the first indexing plate;

[0090] (2) Rotate the first indexing plate to the correction station, and perform position correction;

[0091] (3) By rotating the first indexing plate to the exchange station, the LED is exchanged to the second indexing plate;

[0092] (4) Rotate to the detection station through the second indexing plate, the image detection device detects the top surface image of the LED, and detects whether the material appearance of the LED is damaged or stained; and performs a spectroscopic test to divide the LED into different categories;

[0093] (5) Exchange the LEDs of the same classification to the first indexing plate, and the LEDs of other classifications are blown down on the second indexing plate to the receiving barrels of different classifications;

[0094](6) Rotate the classified LEDs to the polarity rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com