Cleaning device for removing sand and soil in dehydrated vegetable raw material without machine halt

A technology for dehydrating vegetables and cleaning devices, applied in the fields of application, food processing, food science, etc., can solve the problems of cumbersome cleaning process and production interruption, and achieve the effect of convenient and convenient cleaning of sediment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

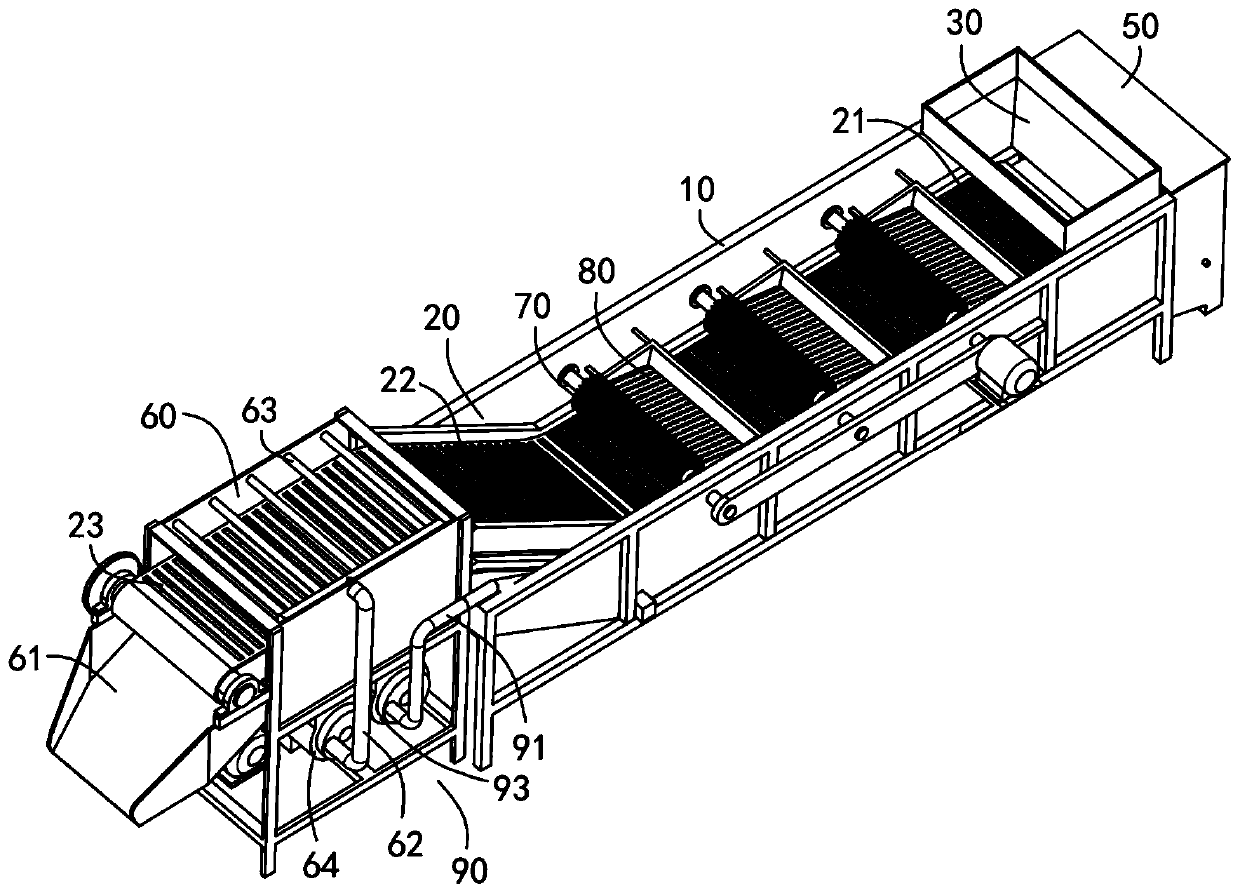

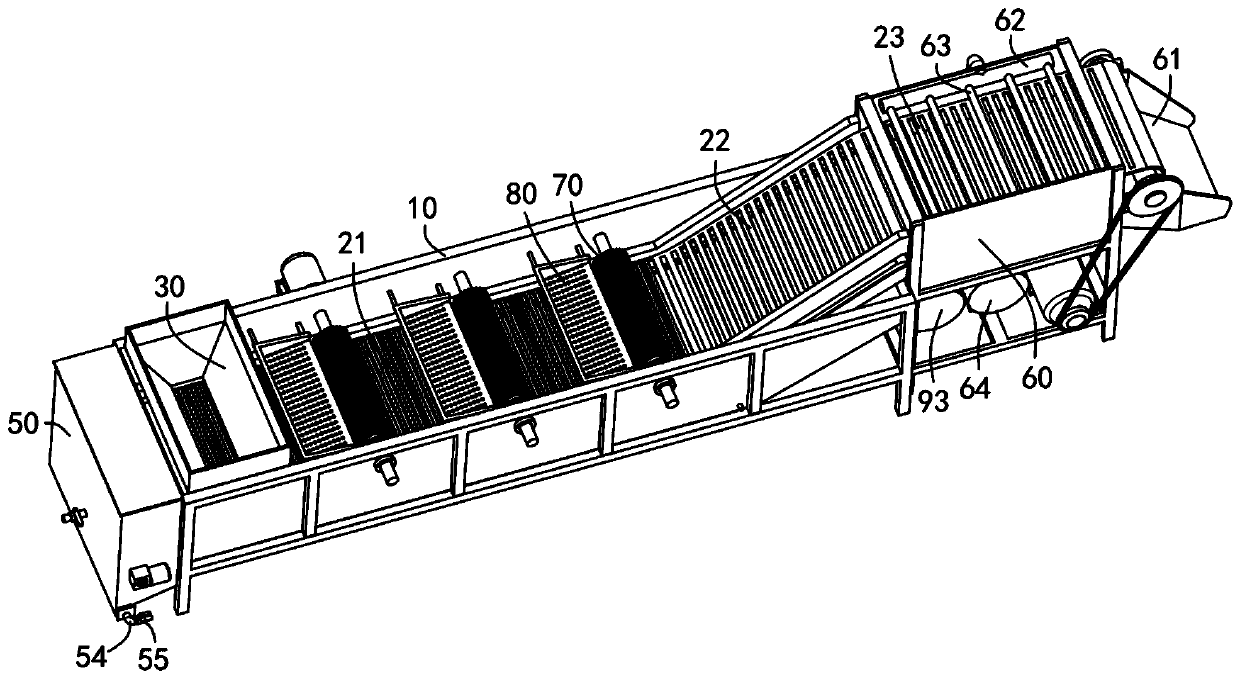

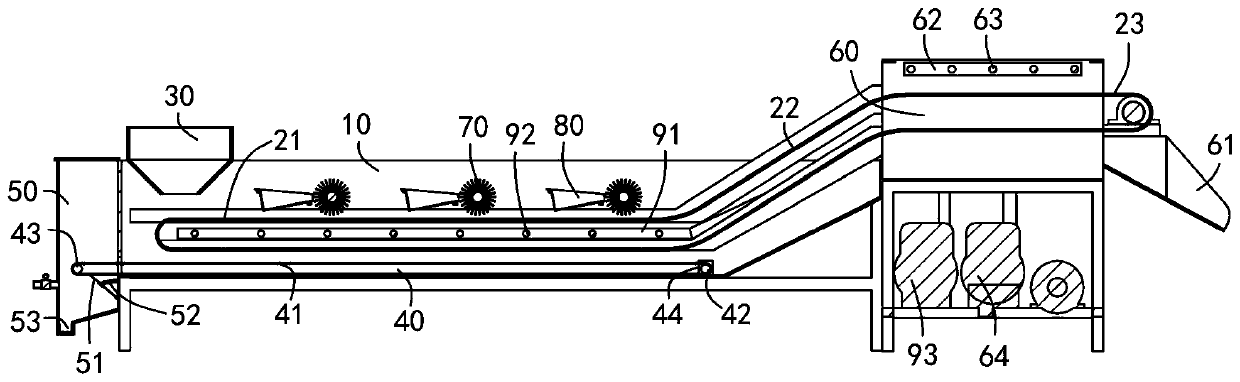

[0022] In order to illustrate the technical solutions of the embodiments of the present invention more clearly, the accompanying drawings used in the embodiments will be briefly introduced below. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

[0023] see Figure 1 to Figure 4 , the embodiment of the present invention provides a cleaning device for removing sediment in dehydrated vegetable raw materials without stopping the machine, including a body 10, a conveying mesh belt 20, a feeding bin 30, a sediment conveying belt conveyor 40, and a sand settling box 50. The body 10 is A flat and long sealed box, the top of the body 10 is open, the conveying mesh belt 20 is built in the body 10, the length direction of the conveying mesh belt 20 is consistent with the length direction of the body 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com