Automatic Control System of Oil Circuit Precision for Engine Fire Resistance Test

A technology of automatic control and fire resistance test, applied in the field of oil circuit precision, can solve the problems that the precision cannot be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

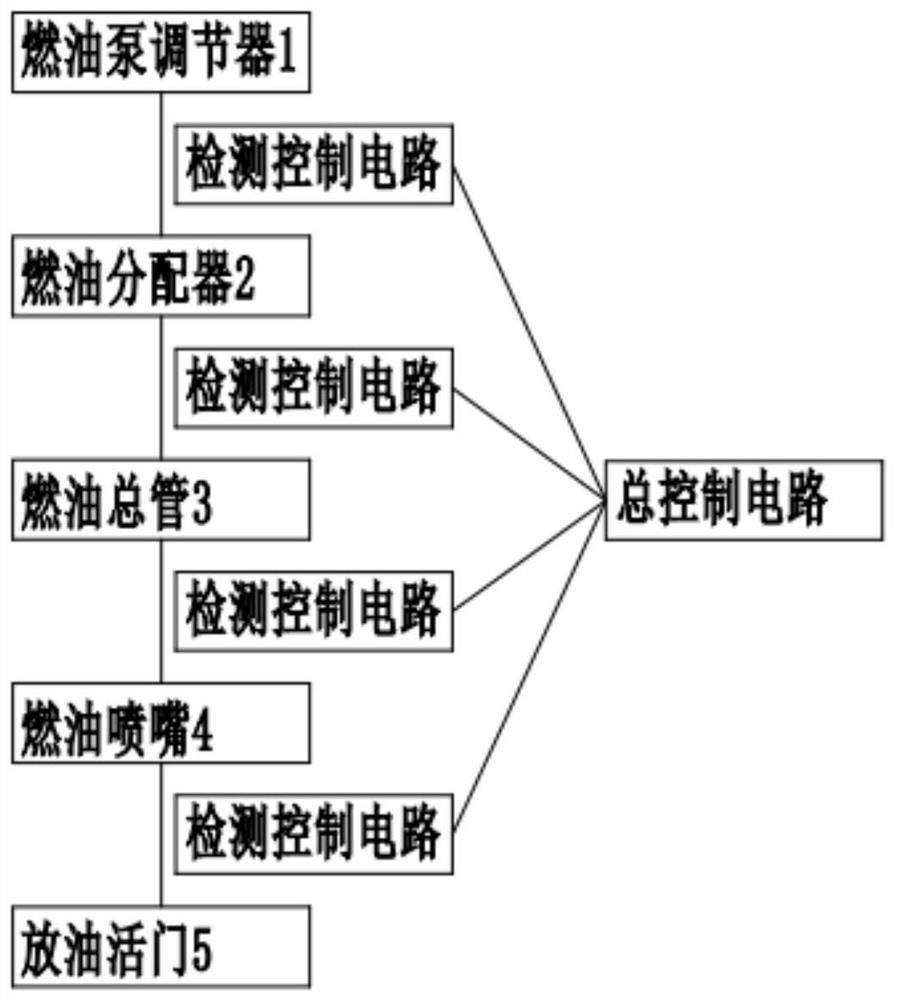

[0022] Embodiment one is basically as attached figure 1 Shown: The automatic control system for the accuracy of the oil circuit in the engine fire resistance test, which is connected to the fuel pump regulator 1, the fuel distributor 2, the fuel main pipe 3, the fuel nozzle 4 and the fuel drain valve 5 to control the amount of corresponding fuel output A stage detection control circuit and a general control circuit connected with all detection control circuits; the general control circuit detects and controls the oil output of each component step by step according to the preset order.

[0023] Each detection control circuit includes a flow sensor and a solenoid valve; the solenoid valve includes a plurality of rotation angle states for controlling the size of the fuel passage.

[0024] The detection and control circuit of each stage detects the oil output of each component oil outlet through the flow sensor, and adjusts the size of the oil outlet through the rotation angle sta...

Embodiment 2

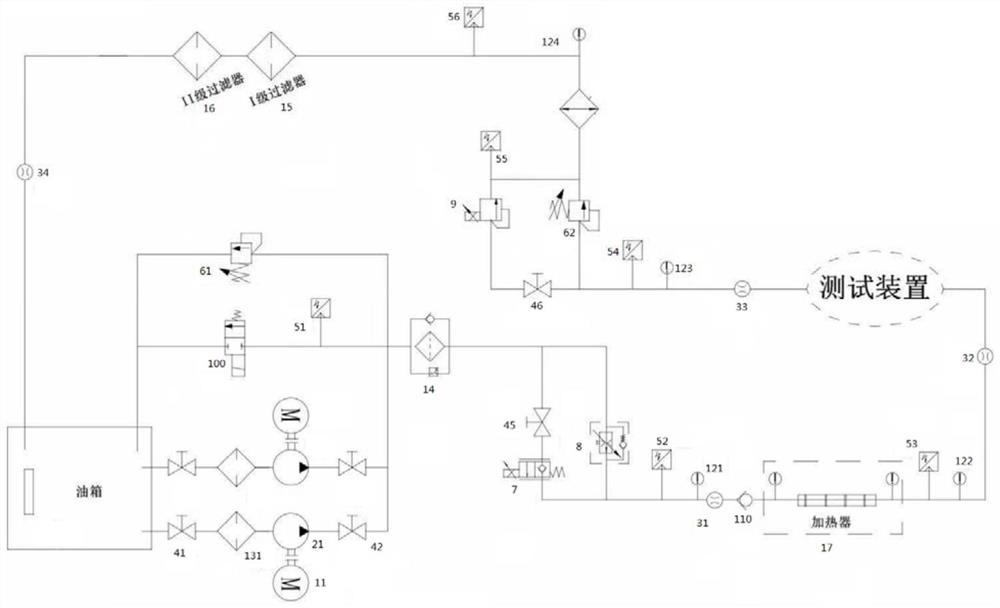

[0054] like figure 2 As shown, the detection and control circuit of each stage in this embodiment is different from that of Embodiment 1. The detection and control circuit of each stage in this embodiment is specifically a circuit circuit installed along the direction of the fuel main pipe 3. In the counterclockwise direction, the outlet of the fuel tank is respectively Connect with four branches.

[0055] The first branch includes a first ball valve 41 , a first oil suction filter 131 , a first oil pump 21 and a second ball valve 42 sequentially connected to the outlet of the oil tank, wherein the first oil pump 21 is connected to the first variable frequency motor 11 .

[0056] The second branch circuit includes a third ball valve, a second oil suction filter, a second oil pump and a fourth ball valve sequentially connected from the outlet of the oil tank, wherein the second oil pump is connected with the second frequency conversion motor.

[0057] The third branch include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com