Throttle valve key opening degree flow detection equipment

A flow detection and throttle valve technology, which is applied in the direction of internal combustion engine testing, etc., can solve the problems of inaccurate exhaust temperature control, large or small flow consistency deviation in the middle opening, and increased air volume control time. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

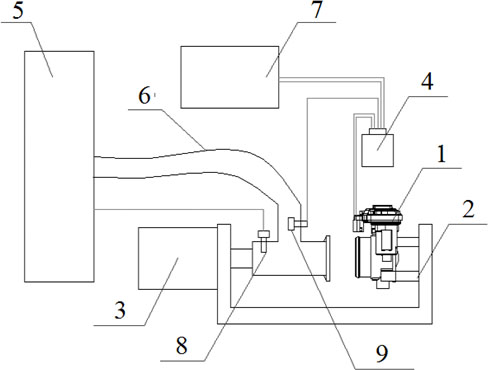

[0017] A throttle key opening flow detection device, its structure is as follows figure 1 As shown, it includes a U-shaped tooling 2, a controller 7, a vehicle computer board 4, and an air supply testing mechanism. The U-shaped tooling 2 is fixed on the work surface, and four passing bolts are arranged on the right inner wall of the U-shaped tooling 2. Install the pin of the throttle, the throttle 1 to be tested is installed in the pin of the inner wall on the right side of the U-shaped tooling 2, and the air supply testing mechanism is arranged on the left side wall of the U-shaped tooling 2.

[0018] The air supply test mechanism is used to compress the throttle valve when detecting the throttle valve, supply air to the throttle valve and perform the test, and when replacing the throttle valve, it is separated from the throttle valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com