A method for controlling the microstructure of the surface layer by ultrasonic rolling

A technology of ultrasonic rolling and microstructure, applied in heat treatment process control, heat treatment equipment, manufacturing tools, etc., can solve the problem of lack of scientific and effective quantitative control methods without considering the grain refinement recrystallization mechanism and its strain rate effect And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] This embodiment is an ultra-high-strength steel (45CrNiMoVA), and the critical strain at which dynamic recrystallization occurs at a high strain rate is obtained. The specific steps and parameters are as follows:

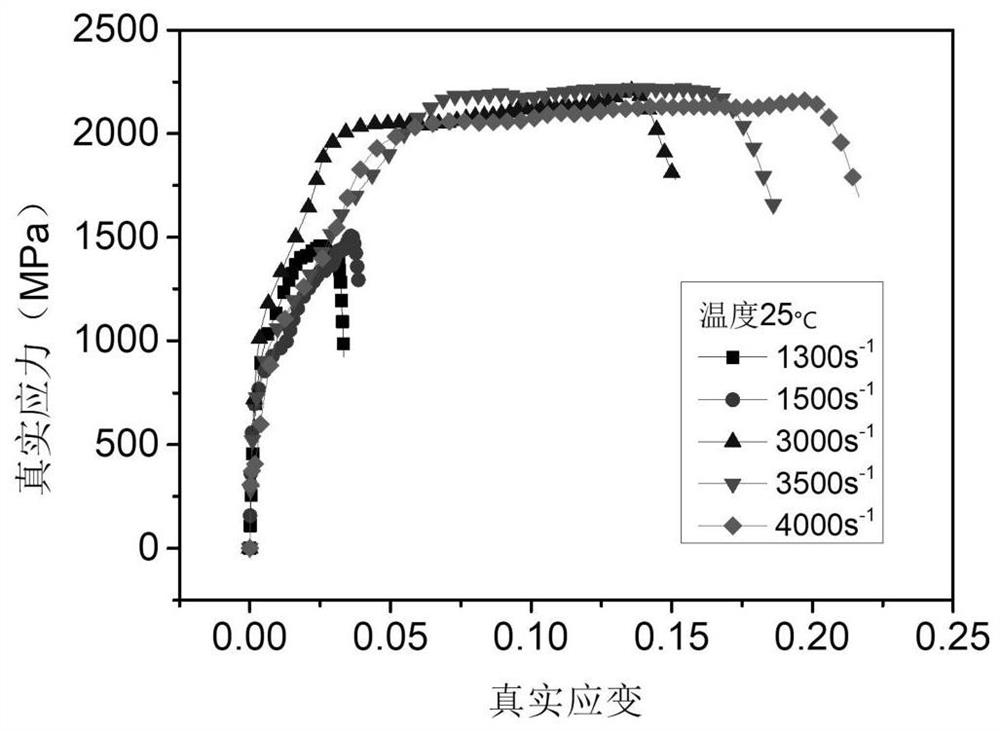

[0015] (1) The heat treatment state of ultra-high-strength steel is high-temperature quenching (870°C) + low-temperature tempering (210°C). Jinsen compression rod (size φ5mm) experiment, obtained high strain rate (1300s -1 、1500s -1 、3000s -1 、3500s -1 、4000s -1 ), the true stress-strain curve under ), such as figure 1 shown.

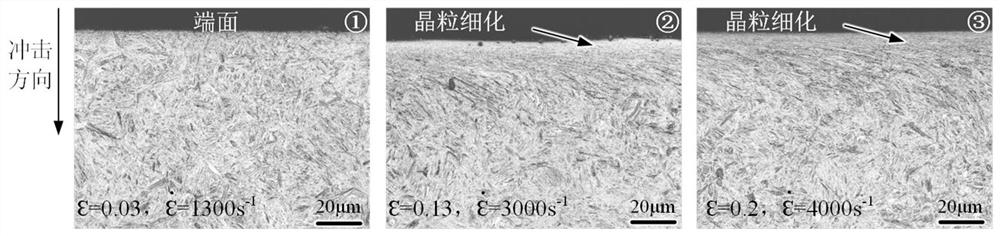

[0016] (2) Polish the deformed sample along the cross-section, corrode it with 4% nitric acid alcohol for 10s, and observe the metallographic structure changes under different deformation conditions, such as figure 2 shown, at a strain rate of 1300s -1 , Under the condition of strain 0.03, the metallographic structure of the sample has no obvious change, and the strain rate is 3000s -1 , strain 0.13 and strain rate 4000s -1 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com