A fire retardant treatment system for wooden fire doors

A flame-retardant treatment and fire-resistant door technology, which is applied in furnaces, mechanical conveyors, electric charge manipulation, etc., can solve the problems of reducing the strength of door panels, failure to balance, and cell structure damage, so as to reduce labor intensity, improve work efficiency, and balance strength The effect of fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in further detail below in conjunction with the accompanying drawings.

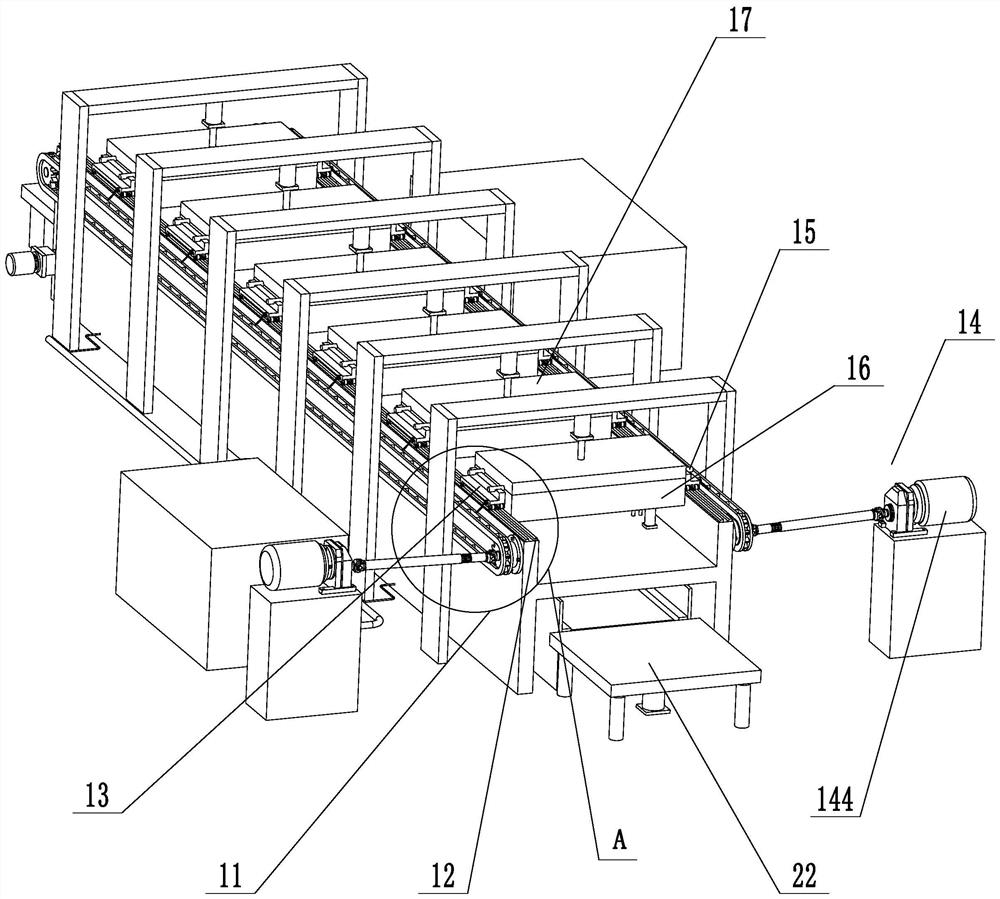

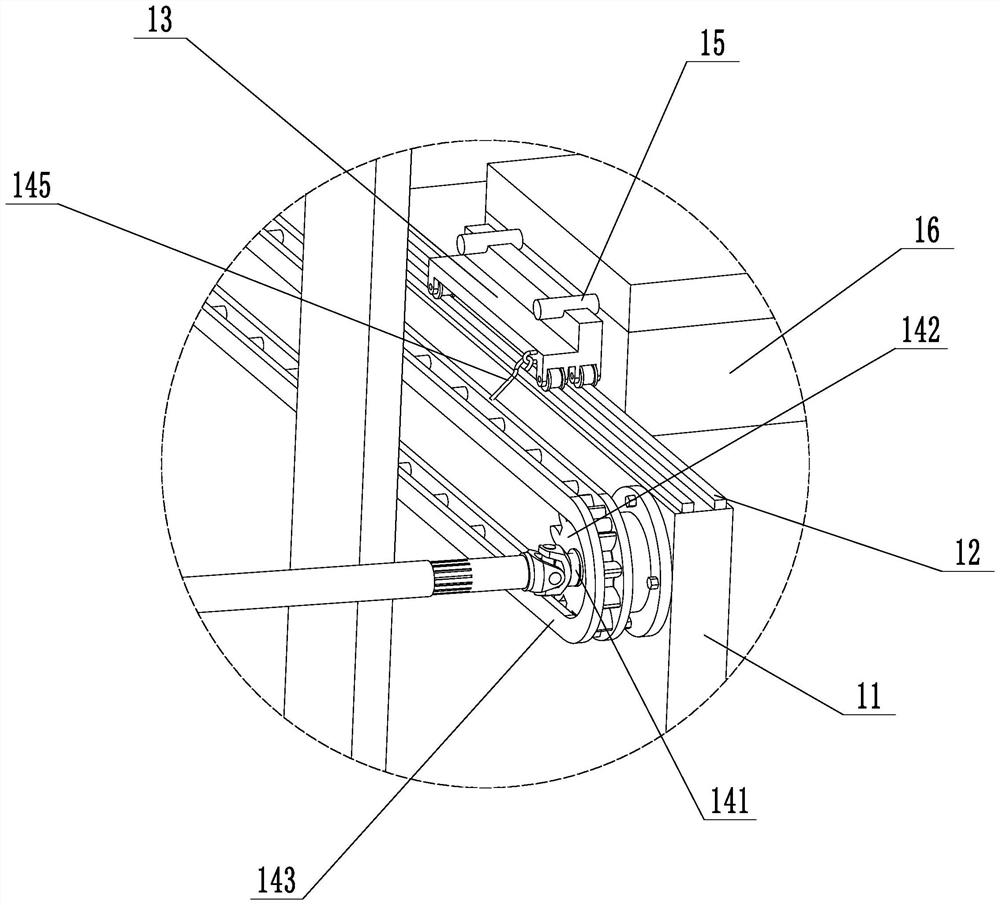

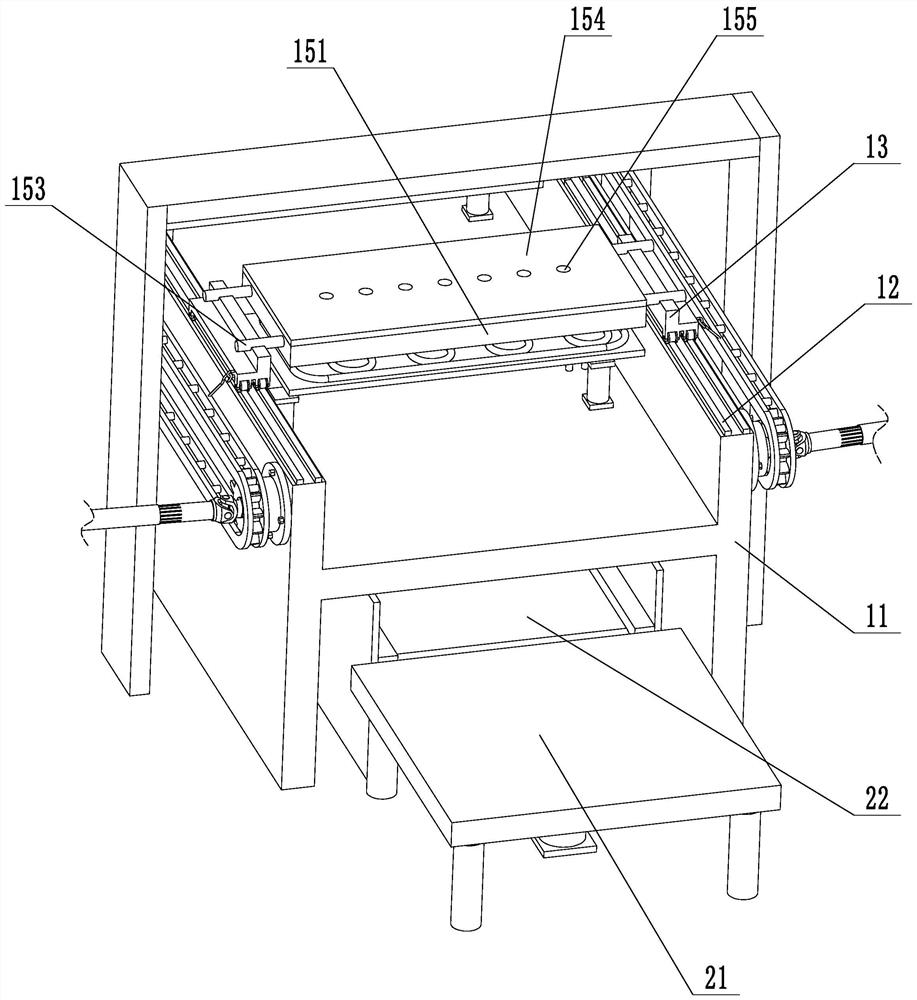

[0061] refer to figure 1 with figure 2 , is a fire retardant treatment system for wooden fire doors disclosed in the embodiment of the present invention, which uses alternating cooling and heating to treat the door, so that the door panel can absorb as much fire retardant liquid as possible without destroying the internal structure of the door panel. The system is mainly composed of workbench 11, track 12, transport trolley 13, driving part 14, jig 15, heating part 16 and cooling part 17, etc. The main part is workbench 11, and two sets of rails are installed on workbench 11. 12. The number of rails 12 in each group is two, and these rails 12 are all parallel to each other and located in the same plane, and are used to provide a moving basis for the transport trolley 13 .

[0062] Transport trolley 13 is mainly made up of car body and the wheel that is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com