Control method for automatic wheel diameter calibration of EMU

A control method and EMU technology, applied in the direction of rim measurement/measurement, railway signal and safety, etc., can solve problems such as loss, and achieve the effects of ensuring effectiveness, saving human resources, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

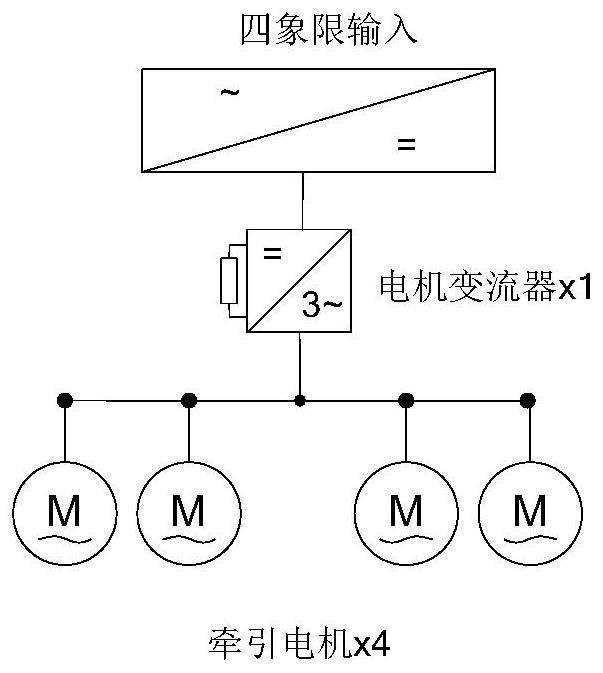

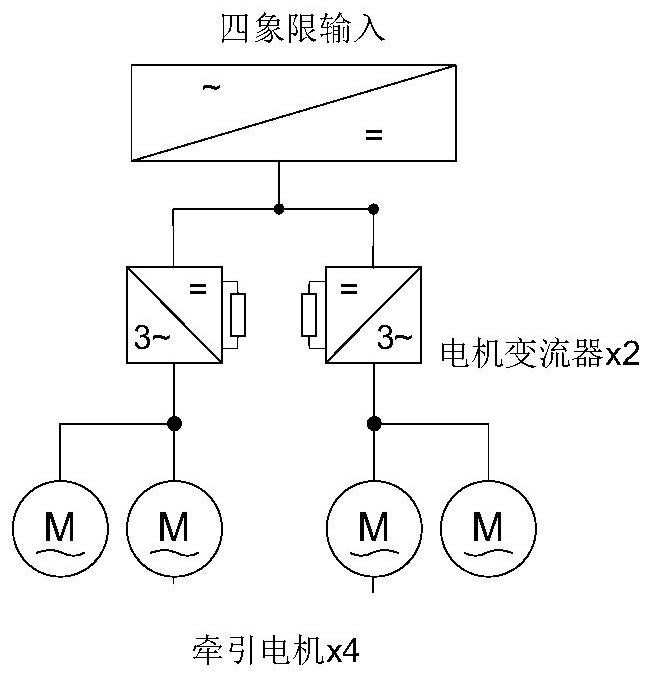

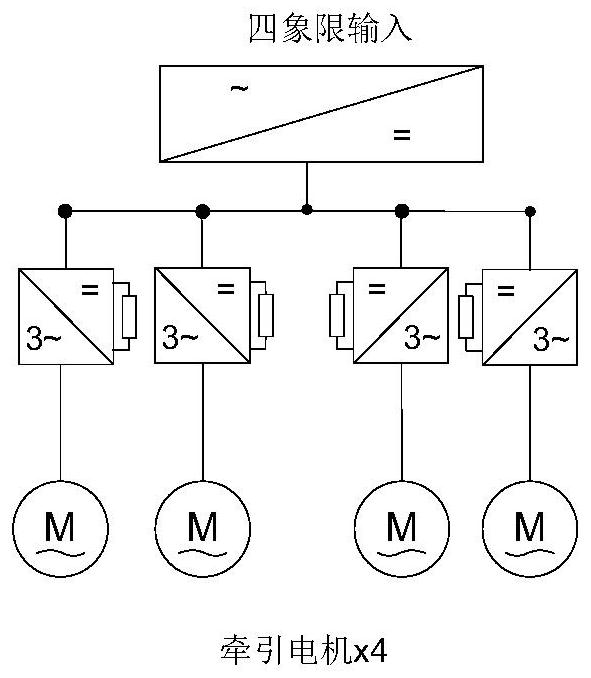

[0026] Embodiment 1, in the existing traction control system of rail vehicles, the traction force is output by the traction motor controlled by the motor converter, and can be divided into three modes: vehicle control, frame control and axle control according to the number of control motors.

[0027] Among them, such as Picture 1-1 The vehicle control method shown is a traction motor with 4 shafts driven by 2 power bogies of 1 motor car with 1 motor converter module;

[0028] Such as Figure 1-2 The rack control mode shown is that one motor converter module drives two traction motors of one power bogie;

[0029] Such as Figure 1-3 The axis control method shown is a traction motor driven by a motor converter module to drive a power bogie.

[0030] In the above three power control methods, each traction motor is equipped with a speed sensor for monitoring the corresponding output shaft.

[0031] Such as figure 2 As shown, in the frame control mode, the two traction motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com